Application of general formula AM<2>O<5-x> compound as catalyst for catalyzing VOC combustion

An am2o5-x, compound technology, applied in the application field of catalyst, can solve the problem of high cost of VOC treatment catalyst, and achieve the effect of good catalytic effect, long service life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

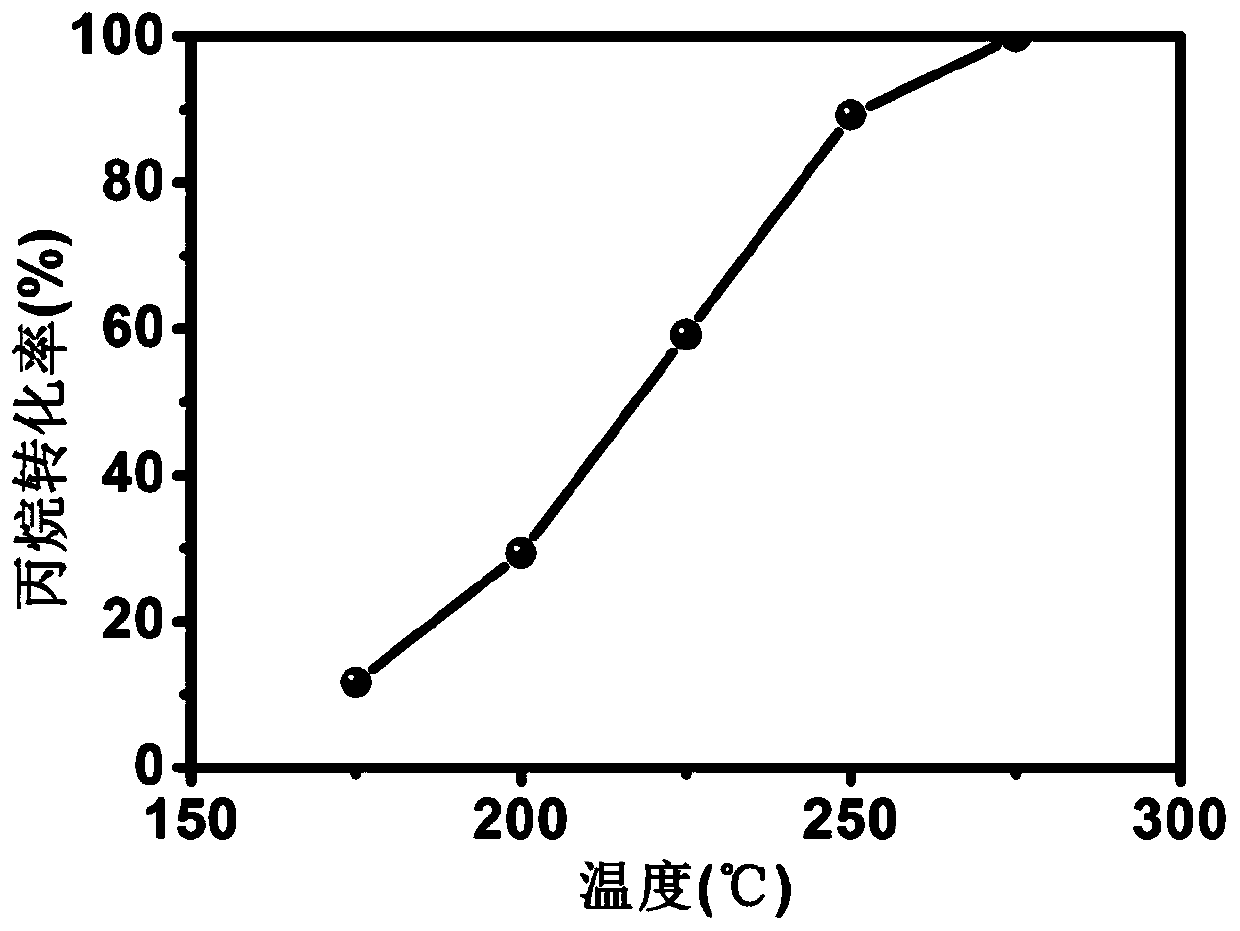

[0046] The VOC gas introduced is propane with a concentration of 1000 ppm, the gas flow rate is 40 ml / min, and the catalyst has a particle size of 20 to 45 nm and a specific surface area of 30 to 55 m. 2 / g of SmMn 2 O 5 After granulation, select particles with a size of 80-100 mesh for propane catalysis, the dosage is 100mg, and the reaction space velocity is 24000ml·g -1 ·H -1 , The conversion rate of propane is represented by the consumption rate of reactants, and the test results are shown in figure 1 . The result shows the T of propane 50 (Representing the temperature at which the conversion rate is 50%) is 217°C, T 90 (Representing the temperature at which the conversion rate is 90%) is 251°C.

Embodiment 2

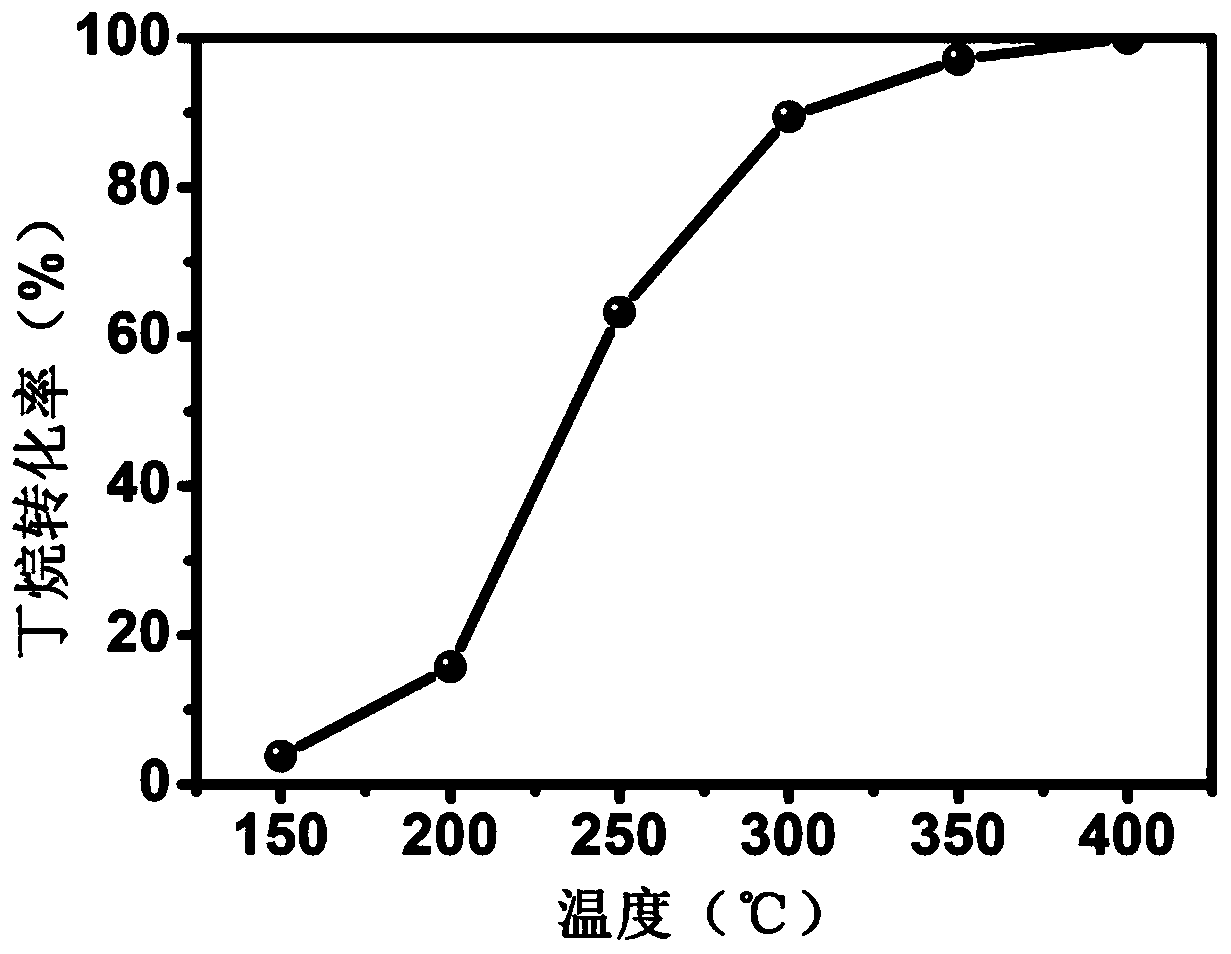

[0048] The VOC gas introduced is butane with a concentration of 1000ppm, the gas flow rate is 40ml / min, the catalyst has a particle size of 20~45nm and a specific surface area of 30~55m 2 / g of SmMn 2 O 5 After granulation, select particles with a particle size of 80-100 mesh for butane catalysis, the dosage is 50mg, and the reaction space velocity is 48000ml·g -1 ·H -1 , The conversion rate of butane is determined by CO 2 Generation rate, see the test results figure 2 . The result shows the T of butane 50 (Representing the temperature when the conversion rate is 50%) is 235℃, T 90 (Represents the temperature at which the conversion rate is 90%) is 300°C.

Embodiment 3

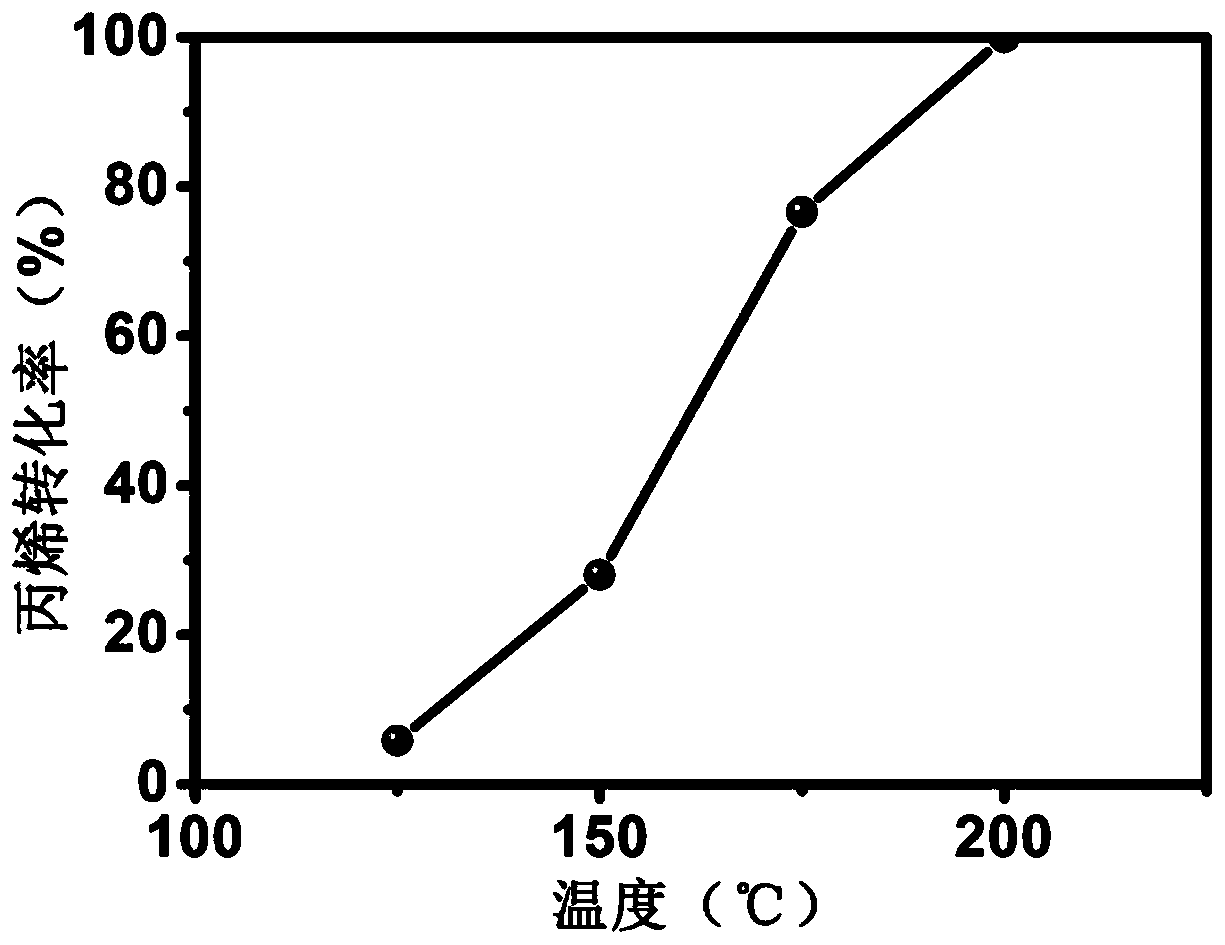

[0050] The VOC gas introduced is propylene with a concentration of 1000ppm, the gas flow rate is 40ml / min, and the catalyst has a particle size of 20~45nm and a specific surface area of 30~55m. 2 / g of SmMn 2 O 5 After granulation, select particles with a size of 80-100 mesh for propylene catalysis, the dosage is 100mg, and the reaction space velocity is 24000ml·g -1 ·H -1 , The conversion rate of propylene is expressed by the consumption rate of reactants, and the test results are shown in image 3 . The result shows that the T of propylene 50 (Representing the temperature at which the conversion rate is 50%) is 161°C, T 90 (Representing the temperature at which the conversion rate is 90%) is 189°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com