Method for preparing gamma-decalactone (GDL) from kitchen waste grease

A technology of waste oil and decanolactone, which is applied in the field of food-grade natural flavor γ-decalactone, can solve the problems of large differences in output, and achieve the effect of saving production costs and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

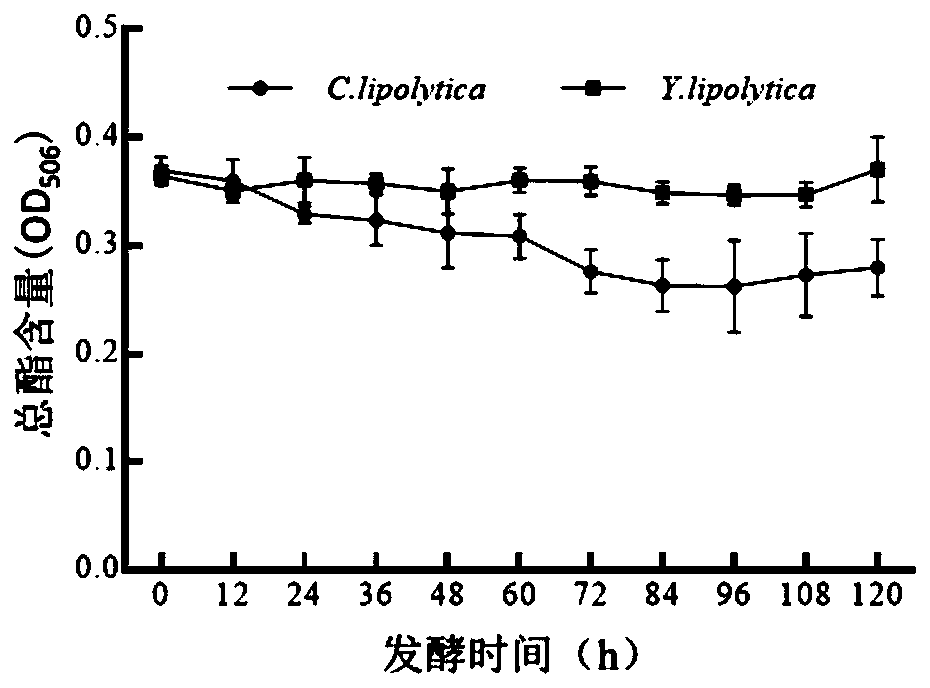

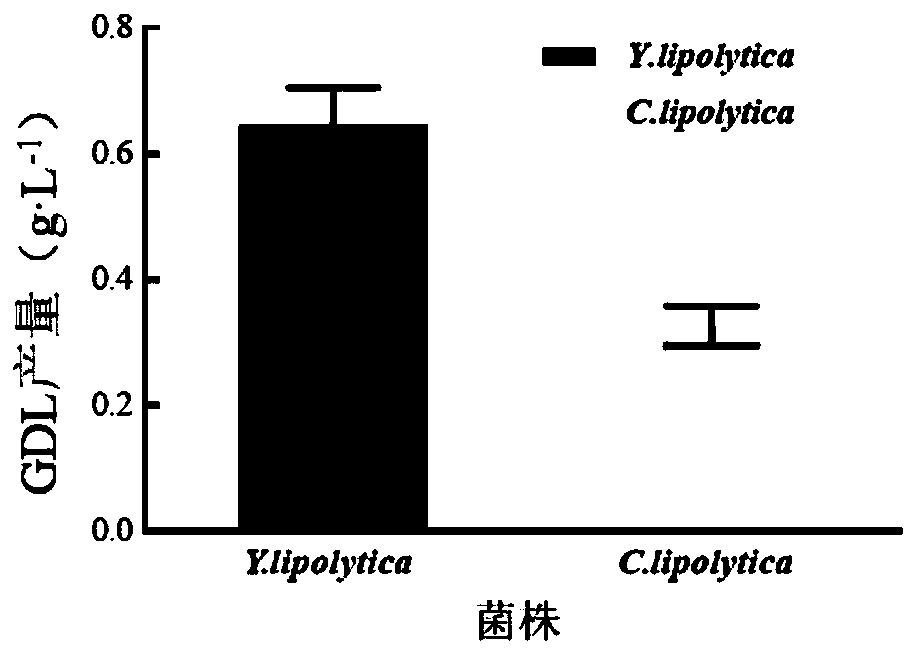

[0031] Example 1 Degradation of oil and production of GDL by two strains of yeast

[0032] 1. Determination of the ability of different yeast strains to degrade esters.

[0033] Esters and lactones react with hydroxylamine under alkaline conditions to form hydroxamic acid, and hydroxamic acid complexes with Fe under acidic conditions to form a purple-red complex. 506 nm absorbs.

[0034] Through screening and verification of various strains, single colonies of Yarrowia lipolytica (Yarrowialipolytica) CICC 32187 and Candida lipolytica (Candida lipolytica) CICC 31223 were finally picked and inoculated in 5 mL of YPD liquid medium, shaken at 28 °C (200r / min) and cultured overnight; transfer the inoculation amount of 10% volume concentration to 30 mL of YPD liquid medium, culture at 28 ° C for 12 h with shaking (200 r / min), centrifuge at 6 000 r / min for 3 min, and buffer the bacterial cells with sorbitol washed twice, and adjust the cell concentration to OD 600 The bacterial s...

Embodiment 2

[0044] Example 2 Using the culture medium mixed with kitchen waste oil to carry out biofermentation of ricinoleic acid to produce gamma-decalactone

[0045] 1. Activation of strains: Inoculate Yarrowia lipolytica CICC 32187 and Candida lipolytica CICC 31223 into YPD medium respectively, culture at 28°C for 2 days for activation, and obtain activated single colonies respectively .

[0046] The quality composition of the YPD medium is as follows: 2% glucose, 2% peptone, 1% yeast powder, 2% agar, deionized water as a solvent, and natural pH. The medium was sterilized at 121 °C for 20 min.

[0047] 2. Seed culture: Pick 3 to 5 single colonies of the above-mentioned activated yeast and inoculate them in a 500mL Erlenmeyer flask containing 300mL seed medium under aseptic conditions, and cultivate them on a shaker at 28-30°C and 150rpm for 1 day , to obtain Yarrowia lipolytica seed liquid and Candida lipolytica seed liquid respectively. No contamination was found through microscop...

Embodiment 3

[0056] Embodiment 3 Utilizes the substratum mixed culture that contains kitchen waste grease to ferment castor oil to produce gamma-decalactone

[0057] Change the ricinoleic acid in step 4 of Example 2 to 80g / L castor oil, and change the kitchen waste oil mass concentration into 3% in the GDL transformation medium, and other operations are the same as in Example 1. The output of 1 liter of fermentation broth was 0.15g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com