A preparation method of a surface-enhanced Raman scattering chip that can be used for trace detection, and the resulting product and application

A surface-enhanced Raman and trace technology, applied in Raman scattering, measuring devices, instruments, etc., can solve the problems of difficult storage of products and complicated preparation process, and achieve excellent performance of surface-enhanced Raman, simple preparation of raw materials, and easy use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]Accurately weigh 800 mg of melamine and dissolve it in 250 mL of ultrapure water, and heat to keep the solution at a constant temperature of 60±5 °C. Under stirring conditions, slowly pour 50 mL of silver nitrate aqueous solution with a concentration of 38 mM into the above-mentioned hot melamine aqueous solution, and continue stirring to obtain a colorless and transparent colloidal solution.

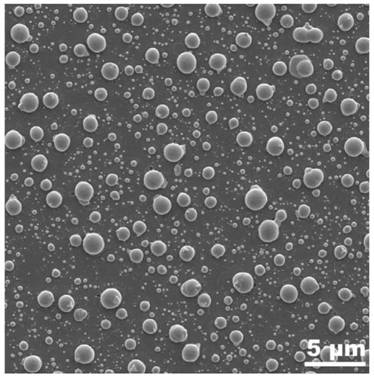

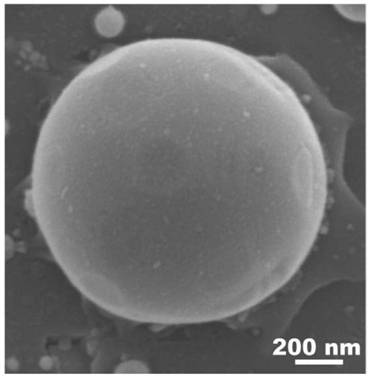

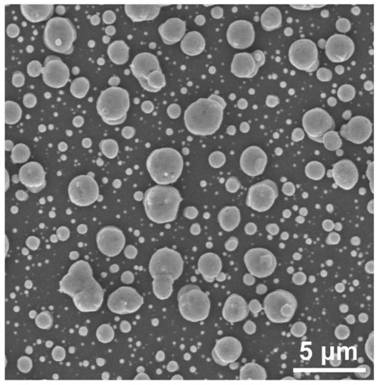

[0042] Take a substrate with a groove capacity of 10 μl, and quickly transfer 10 μl of the above colloid solution to each groove of the array substrate with a pipette. All the solvents in the grooves are volatilized, and the white xerogel film evenly covers the bottom of each groove. Transfer the above-mentioned substrate containing the xerogel film to a muffle furnace, slowly raise the temperature to 450°C at a rate of 2°C / min in an air atmosphere, and keep the temperature at this temperature for 180min to remove the organic components and make the precious metal The ions are re...

Embodiment 2

[0044] Accurately weigh 400 mg of carbonamide and dissolve it in 250 mL of ultrapure water, and slowly pour 50 mL of silver nitrate aqueous solution with a concentration of 38 mM into the above carbonamide aqueous solution under stirring at room temperature, and continue stirring to obtain a colorless and transparent colloidal solution.

[0045] Take a substrate with a groove capacity of 50 μl, and quickly transfer 50 μl of the above colloid solution to each groove of the array substrate with a pipette. All the solvents in the grooves are volatilized, and the white xerogel film evenly covers the bottom of each groove. Transfer the above-mentioned substrate containing the xerogel film to a muffle furnace, slowly raise the temperature to 400°C at a rate of 5°C / min under a nitrogen atmosphere, and keep the temperature at this temperature for 120min to remove the organic components and make the precious metal The ions are reduced to a noble metal film with a rough surface, and th...

Embodiment 3

[0047] Accurately weigh 550 mg of thiourea and dissolve it in 250 mL of ultrapure water, and slowly pour 100 mL of 20 mM sodium chloroaurate aqueous solution into the above-mentioned thiourea aqueous solution under stirring at room temperature, and continue stirring to obtain light Yellow transparent colloidal solution.

[0048] Take a substrate with a groove capacity of 100 μl, and quickly transfer 100 μl of the above colloid solution to each groove of the array substrate with a pipette. All the solvents in the grooves were volatilized, and the light yellow xerogel film evenly covered the bottom of each groove. Transfer the above-mentioned substrate containing the xerogel film to a muffle furnace, slowly raise the temperature to 500 °C at a rate of 10 °C / min in the air, and keep the temperature at this temperature for 60 min to remove the organic components and make the noble metal ions After reducing to a noble metal film with a rough surface, and then naturally cooling to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com