Oxidation resistant copper-based electrically conductive paste and preparation method thereof

A technology of conductive paste and copper oxide, which is applied in the direction of conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., can solve the problem of increased resistivity, large local resistance, and large surface energy of electronic pastes and other problems, to achieve the effect of improving antioxidant performance, good antioxidant performance, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

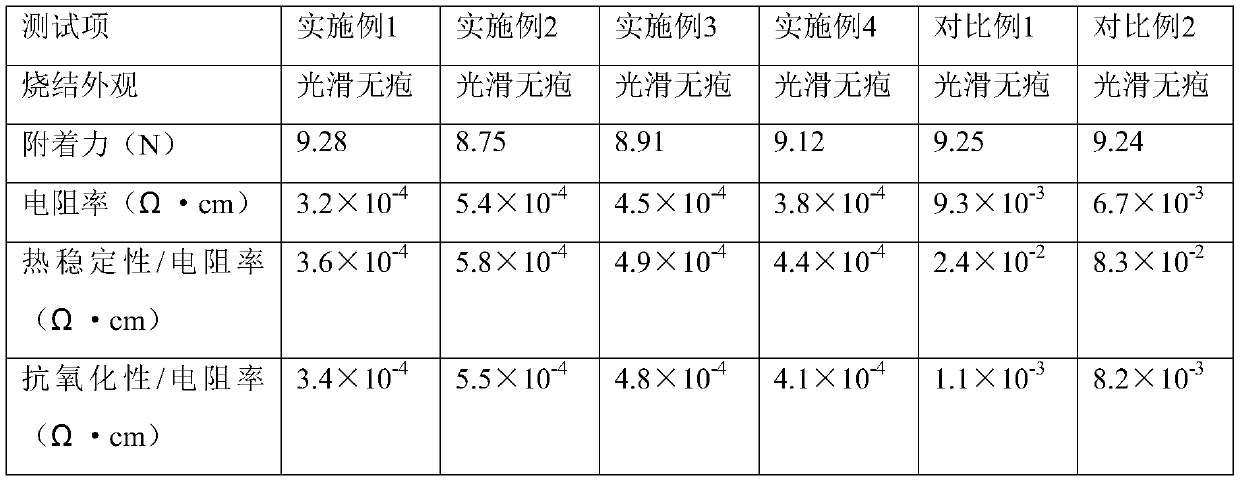

Examples

Embodiment 1

[0019] A preparation method for oxidation-resistant copper-based conductive paste, comprising the following steps:

[0020] (1) Add 65 parts of copper powder to 45 parts of aqueous solution containing 15wt% dispersant, add 12 parts of 0.5M hydrochloric acid solution under agitation, then add 8 parts of 3mg / mL aniline in ethanol solution, at room temperature Stir and mix for 30 minutes; then add 3 parts of chloroform and stir for 8 minutes;

[0021] (2) Add 6 parts of hydrochloric acid solutions containing 3wt% ammonium persulfate to the solution prepared in step (1) under the condition of an ice bath, and react for 3.5h under stirring; remove the precipitate in the reaction system by suction filtration The substance was intercepted, and washed 4 times with ethanol solution, and finally washed once with aqueous solution, and the precipitate was resuspended in 45 parts of step (1) in the aqueous solution containing 15wt% dispersant to prepare mixture A;

[0022] (3) AgNO 3 Add...

Embodiment 2

[0029] A preparation method for oxidation-resistant copper-based conductive paste, comprising the following steps:

[0030] (1) Add 50 parts of copper powder to 30 parts of aqueous solution containing 10wt% dispersant, add 8 parts of 0.5M hydrochloric acid solution under stirring conditions, then add 5 parts of 1mg / mL aniline ethanol solution, at room temperature Stir and mix for 20 minutes; then add 2 parts of chloroform and stir for 5 minutes;

[0031] (2) Add 4 parts of hydrochloric acid solutions containing 1wt% ammonium persulfate to the solution prepared in step (1) under the condition of an ice bath, and react for 2h under stirring; remove the precipitate in the reaction system by suction filtration Carry out interception, and wash with ethanol solution 3-5 times, finally wash again with aqueous solution, resuspend the precipitate in 30 parts of aqueous solution containing 10wt% dispersant in step (1), and prepare mixture A;

[0032] (3) AgNO 3 Added to the mixture A ...

Embodiment 3

[0039] A preparation method for oxidation-resistant copper-based conductive paste, comprising the following steps:

[0040] (1) Add 60 parts of copper powder to 40 parts of aqueous solution containing 12wt% dispersant, add 10 parts of 0.6M hydrochloric acid solution under stirring conditions, then add 6 parts of 2 mg / mL aniline ethanol solution, and at room temperature Stir and mix for 25 minutes; then add 2.5 parts of chloroform and stir for 6 minutes;

[0041](2) 5 parts of hydrochloric acid solutions containing 2wt% ammonium persulfate were added in the solution prepared in step (1) under the condition of ice bath, and reacted for 3h under stirring; the precipitate in the reaction system was removed by suction filtration Carry out interception, and wash with ethanol solution 3-5 times, finally wash once again with aqueous solution, resuspend the precipitate in 40 parts of the aqueous solution containing 12wt% dispersant in step (1), make mixture A;

[0042] (3) AgNO 3 Add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com