Preparation method and application of a metal-organic framework core-shell porous nickel sulfide electrode material

A metal-organic framework and electrode material technology, applied in the direction of hybrid capacitor electrodes, can solve the problems that cannot meet the needs of large-scale storage devices, and achieve good cycle characteristics, large capacity, and the effect of relieving physical stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0032]A preparation method based on a metal-organic framework core-shell porous nickel sulfide electrode material, comprising the steps of:

[0033] Step 1. Dissolve a certain quality of soluble nickel salt in a certain volume of anhydrous methanol, stir evenly, then add a certain quality of trimesic acid, and stir for a certain period of time to obtain a mixed solution A for use;

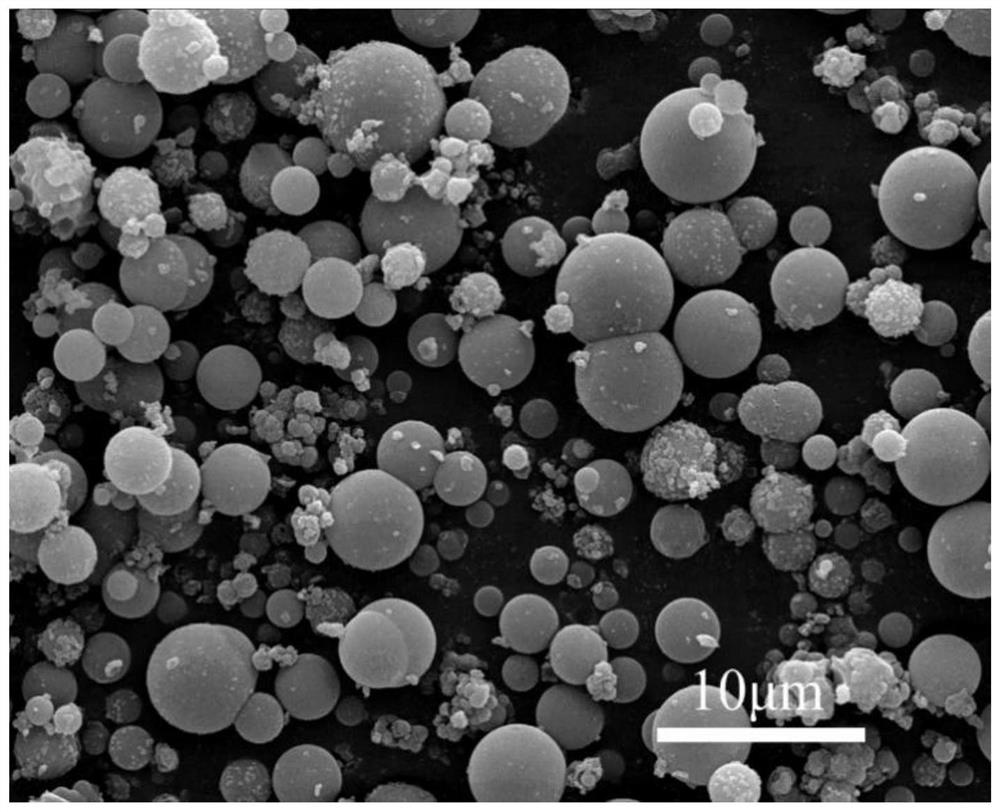

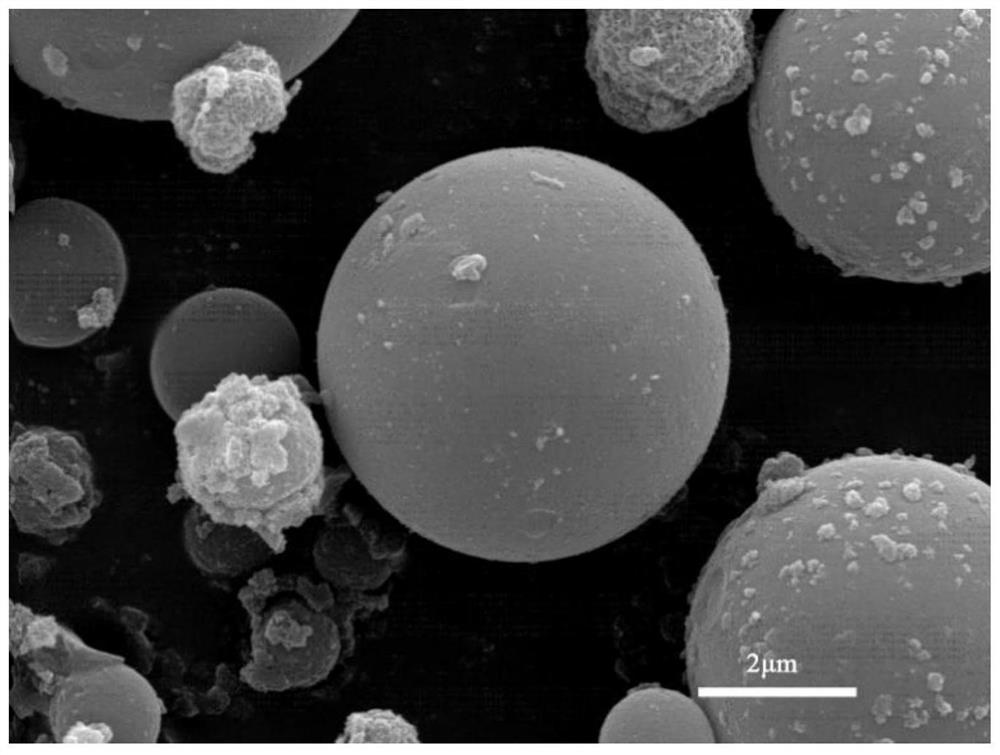

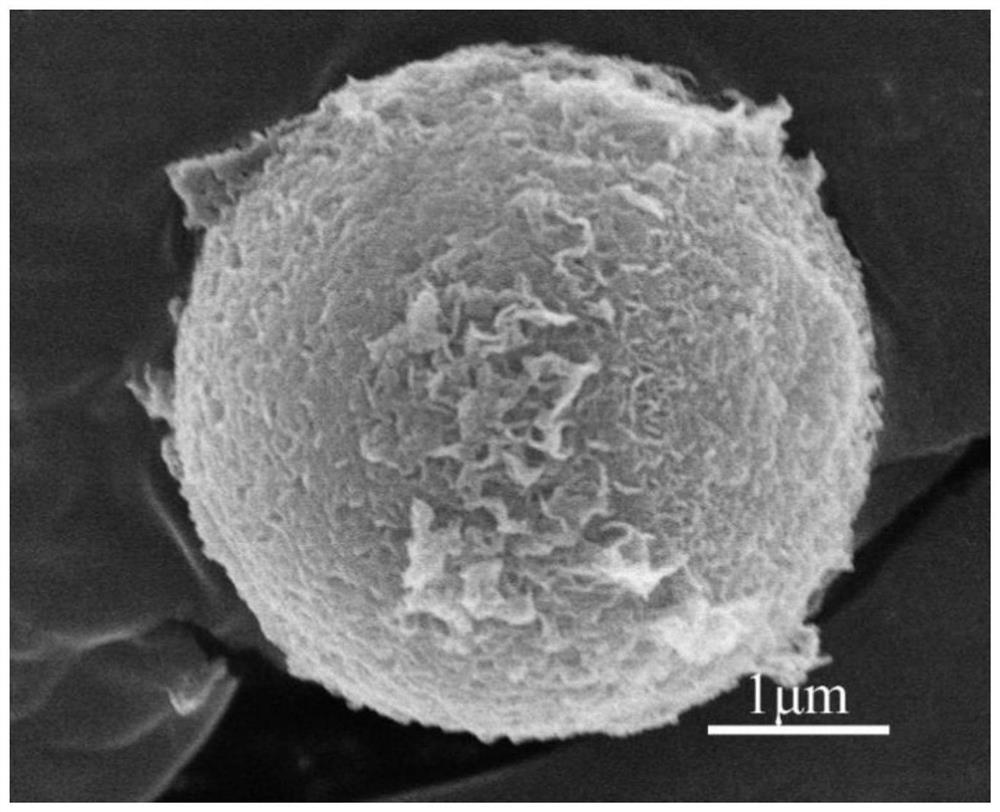

[0034] Step 2. Add the mixed solution A obtained in step 1 into a high-pressure reactor, place the reactor in an oven and heat it for a certain period of time, then cool it down to room temperature naturally, and centrifuge the obtained mixture for 3 times with anhydrous methanol and deionized water. Obtain spherical nickel metal organic framework material after drying, stand-by;

[0035] Step 3, ultrasonically dispersing a certain mass of the spherical nickel metal organic framework material prepared in step 2 in a certain volume of absolute ethanol, then slowly adding a certain volume of sodium s...

specific Embodiment approach 2

[0047] According to the preparation method of a metal-organic framework-based core-shell porous nickel sulfide electrode material described in the first embodiment, the metal-organic framework-based core-shell porous nickel sulfide electrode material is prepared, and the prepared Ni 3 S 4 materials for supercapacitor materials.

[0048] The cyclic voltammetry curve of the porous nickel sulfide electrode material based on the metal-organic framework core-shell described in this embodiment as a supercapacitor material is as follows Figure 9 As shown, the scanning speed of cyclic voltammetry is 5mv / s, 10mv / s, 20mv / s, 30mv / s, 50mv / s, and 80mv / s. It can be seen from the figure that at 5mv / s, 10mv / s , 20mv / s scanning speed, charging and discharging have obvious redox peaks.

[0049] The charge-discharge curve of the metal-organic framework-based core-shell porous nickel sulfide electrode material described in this embodiment is as follows: Figure 10 As shown, the charge and dis...

specific Embodiment approach 3

[0050] A preparation method based on a metal-organic framework core-shell porous nickel sulfide electrode material, comprising the steps of:

[0051] Step 1. Dissolve a certain quality of soluble nickel salt in a certain volume of anhydrous methanol, stir evenly, then add a certain quality of trimesic acid, and stir for a certain period of time to obtain a mixed solution A for use;

[0052] Step 2. Add the mixed solution A obtained in step 1 into a high-pressure reactor, place the reactor in an oven and heat it for a certain period of time, then cool it down to room temperature naturally, and centrifuge the obtained mixture for 3 times with anhydrous methanol and deionized water. Obtain spherical nickel metal organic framework material after drying, stand-by;

[0053] Step 3, ultrasonically dispersing a certain mass of the spherical nickel metal organic framework material prepared in step 2 in a certain volume of absolute ethanol, then slowly adding a certain volume of sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com