Cylinder type series-connection line direct-current monopole motor

A unipolar motor and circuit technology, applied in electrical components, electromechanical devices, etc., can solve problems such as restricting the practical development process of unipolar superconducting motors, difficulty, corrosion, etc., to improve the effective current-carrying density and stability. Improve power density and efficiency, time-stretching effect of pulsed current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

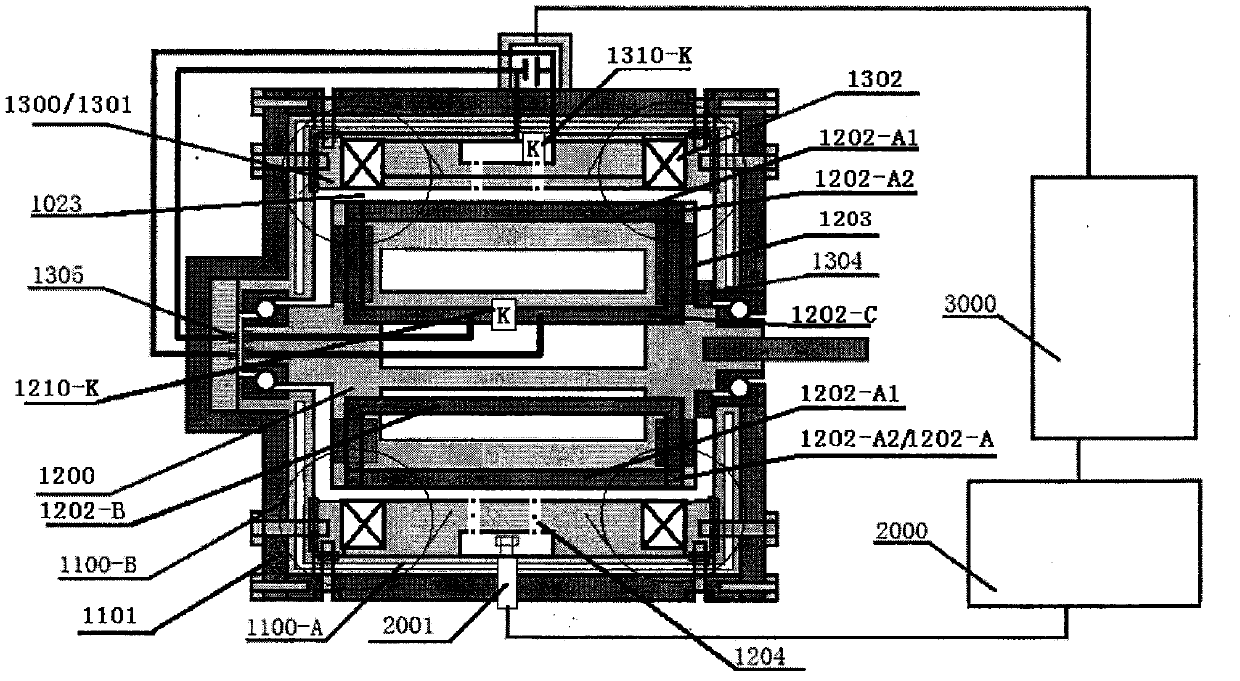

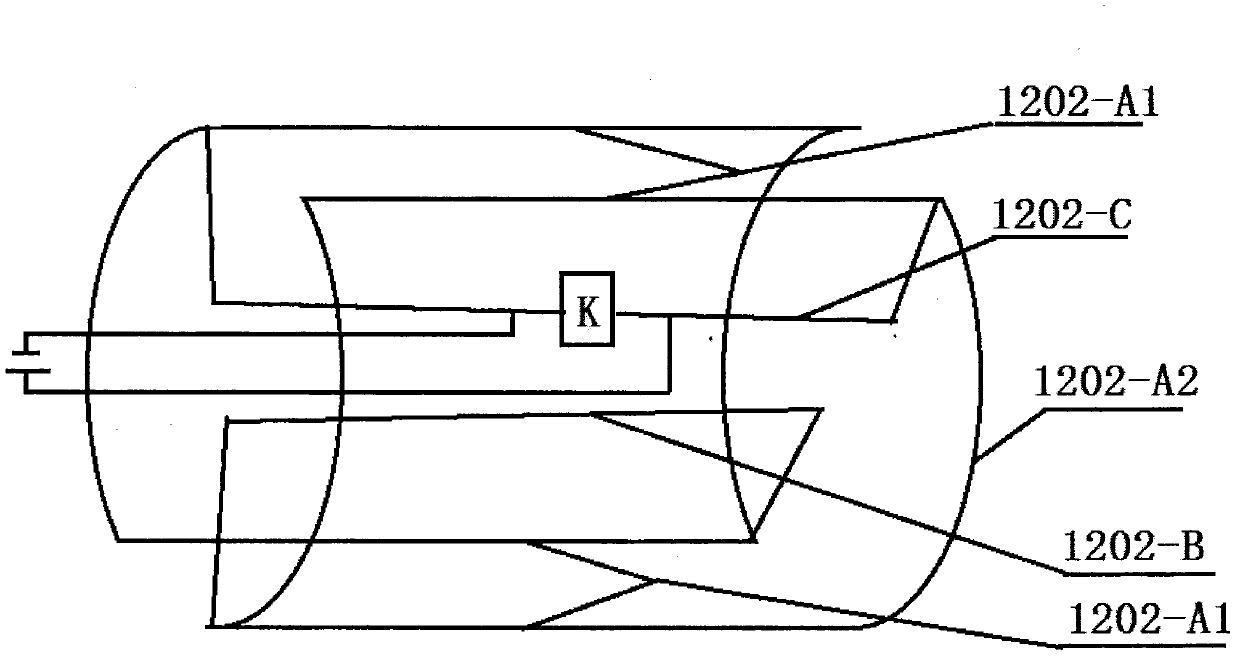

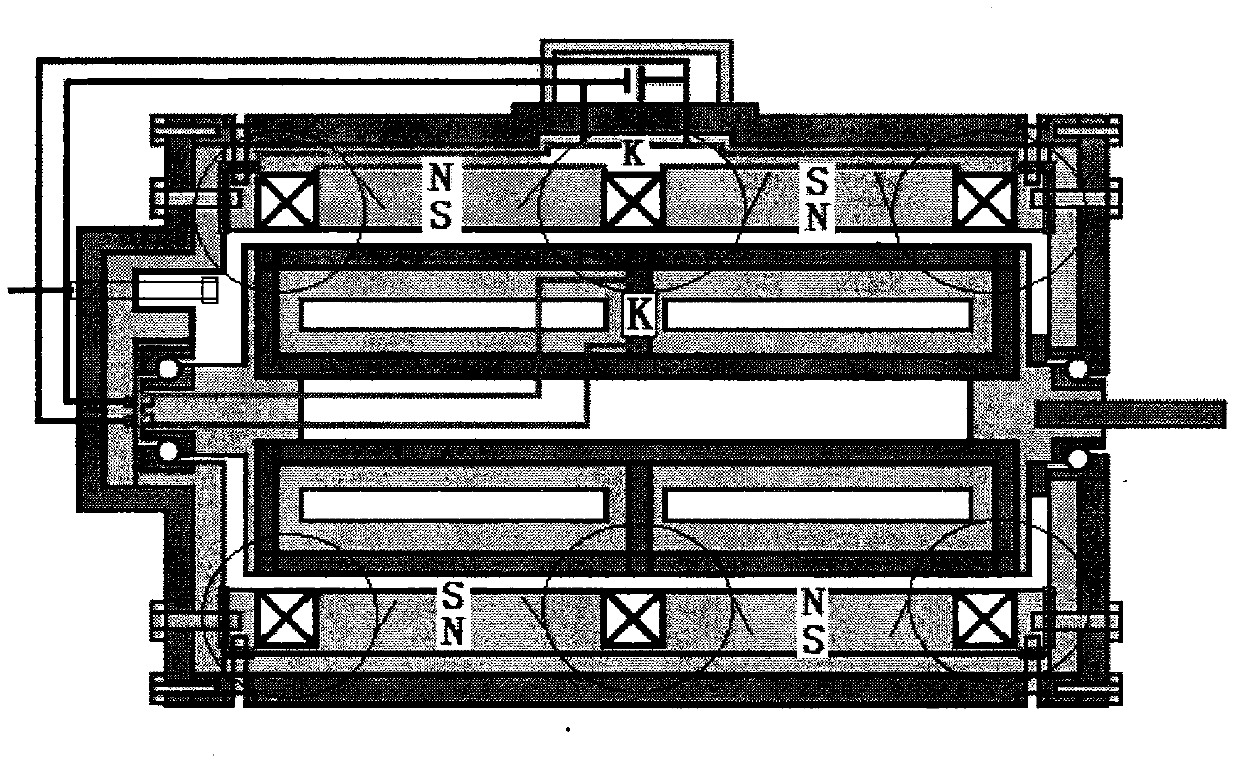

Embodiment 1

[0028] Example 1: Ferromagnetic material-oriented silicon steel is selected as the casing (1100), the hollow cylindrical glass fiber reinforced plastic is arranged on the inner wall of the cylindrical shell (1100-A), and the hollow disc glass fiber reinforced plastic is arranged on the disc end cover (1100-B). The inner wall and the hollow layer are evacuated to 10 -5 Torr vacuum is maintained for static vacuum as the thermal insulation layer, which is a low-temperature chamber (1101); the cylindrical glass fiber reinforced plastic is used as the cylindrical rotor (1201), and YBCO high-temperature superconducting tape is selected by segment welding or 3D printing. Open-loop squirrel cage armature (1202), each group of parallel armature lines (1202-A2) parallel 4 axial armature lines (1202-A1), and set on the barrel rotor (1201), series armature The circuit (1202-B) is connected in series with each group of parallel armature circuits (1202-A2) to form an open-loop squirrel cage s...

Embodiment 2

[0038] Embodiment 2: The difference from Embodiment 1 is that an external prime mover provides mechanical kinetic energy to make the barrel rotor (1201) rotate, and the axial armature circuit (1202-A1) of the rotor part cuts 2 ring super The unipolar radial magnetic field lines generated by the excitation coil (1302) generate a stable direct current induced current, which can be used as a generator by connecting an external energy storage device or an electrical device or a networked power supply.

Embodiment 3

[0039] Embodiment 3: The difference from Embodiments 1 to 2 above is that the open-loop squirrel cage armature (1202) uses conventional copper armature windings, and the superconducting coils are arranged in a toroidal low-temperature container. Watt conduction refrigeration provides support.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com