Brazing method for improving connecting strength of PDC and steel matrix

A technology of connection strength and brazing method, applied in the direction of welding/welding/cutting articles, welding equipment, other manufacturing equipment/tools, etc., can solve the problem that the shear strength and impact resistance toughness cannot meet the brazing strength of polycrystalline diamond composite sheet , the influence of wear resistance of PDC composite sheets, and the large difference in thermal expansion coefficient, etc., to improve the flow spreadability, reduce slag inclusions and pores, and increase the brazing area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

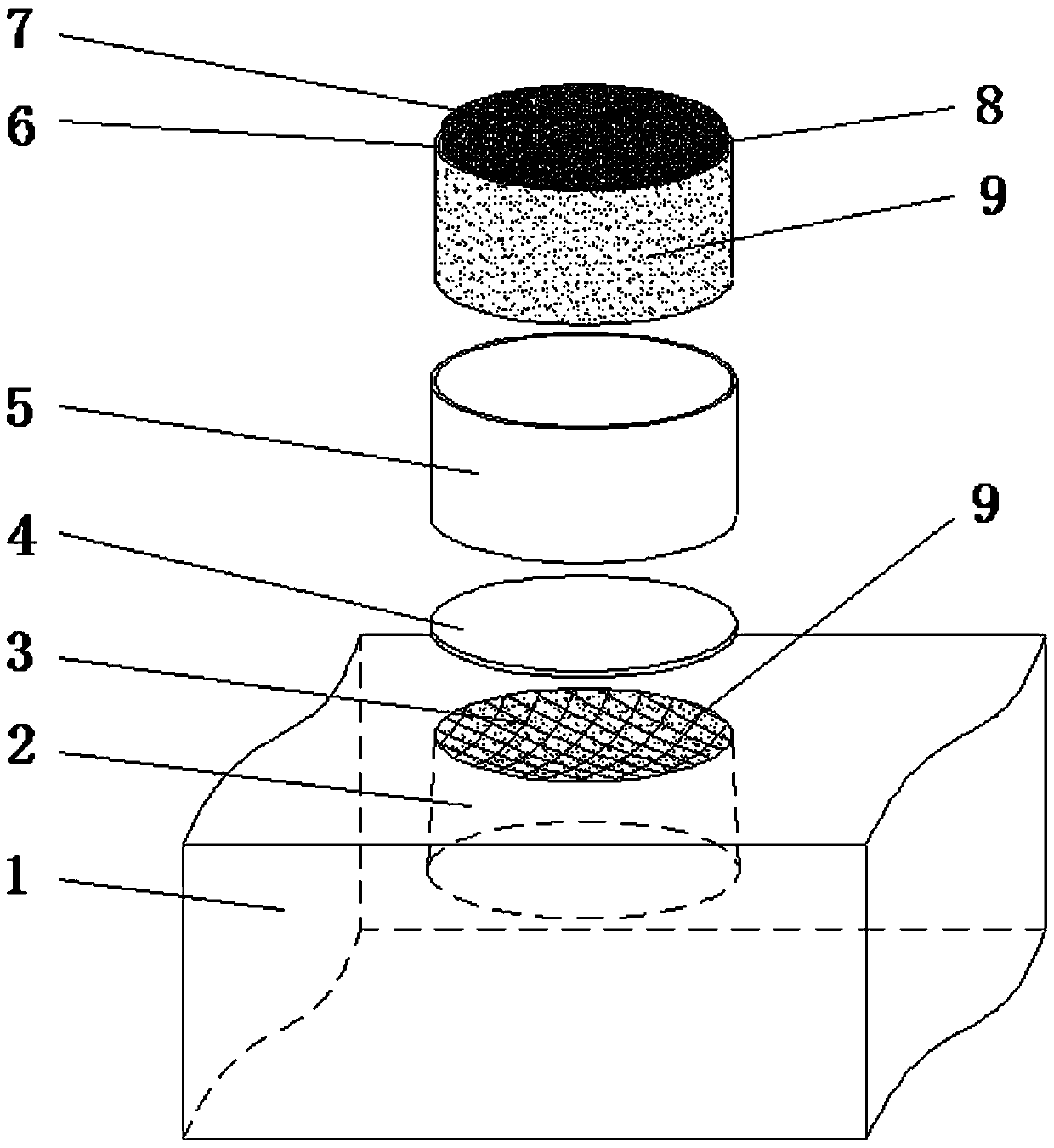

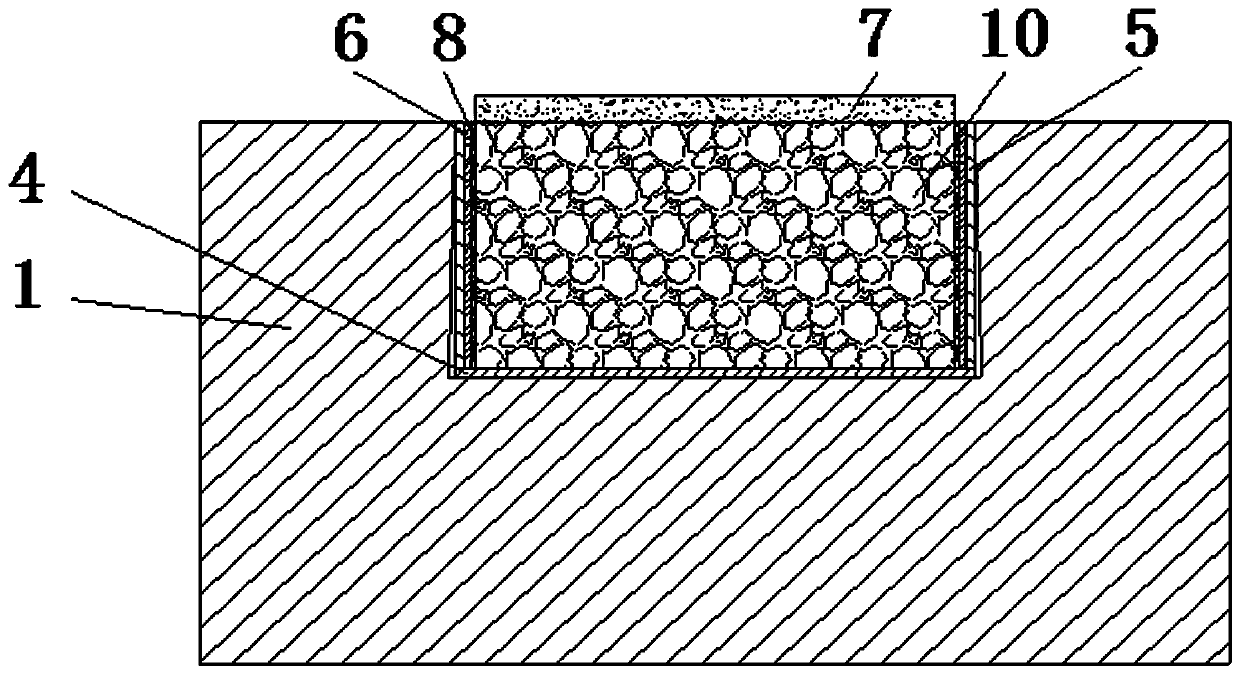

[0063] A brazing method for improving the connection strength between PDC and steel matrix mainly includes the following steps:

[0064] Step 1: Carry out grinding, alkali washing, pickling, acetone scrubbing and distilled water washing on the drill bit steel substrate 1 and the PDC cemented carbide segment 10 in sequence, and air dry for later use;

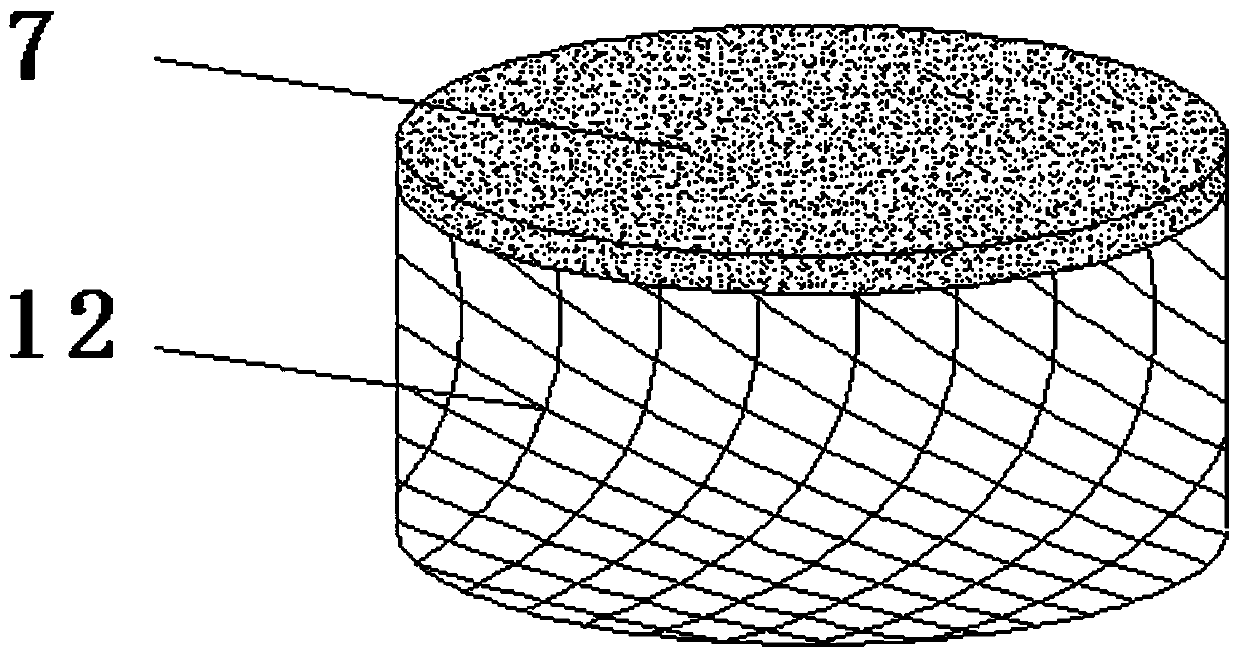

[0065] Step 2: Carry out laser etching treatment on the PDC cemented carbide section 10 air-dried in step 1. The method of carrying out laser etching treatment on the PDC cemented carbide section is: use laser to etch the peripheral surface of the PDC cemented carbide section into regular Or irregular striped lines 11 or reticular lines 12, the depth of the striped lines 11 and the reticular lines 12 is 0.05 mm, the line spacing is 1mm, and the PDC cemented carbide segments 10 after the laser etching process are sequentially electroless plated Cobalt and electroplating nickel treatment, the method for described electroless cobalt...

Embodiment 2

[0072] A brazing method for improving the connection strength between PDC and steel matrix mainly includes the following steps:

[0073] Step 1: Carry out grinding, alkali washing, pickling, acetone scrubbing and distilled water washing on the drill bit steel substrate 1 and the PDC cemented carbide segment 10 in sequence, and air dry for later use;

[0074] Step 2: Carry out laser etching treatment on the PDC cemented carbide section 10 air-dried in step 1. The method of carrying out laser etching treatment on the PDC cemented carbide section is: use laser to etch the peripheral surface of the PDC cemented carbide section into regular Or irregular striped lines 11 or reticular lines 12, the depth of the striped lines 11 and the reticular lines 12 is 0.08 mm, the line spacing is 2mm, and the PDC cemented carbide segments 10 after the laser etching process are sequentially electroless plated Cobalt and electroplating nickel treatment, make PDC cemented carbide section form one ...

Embodiment 3

[0081] A brazing method for improving the connection strength between PDC and steel matrix mainly includes the following steps:

[0082] Step 1: Carry out grinding, alkali washing, pickling, acetone scrubbing and distilled water washing on the drill bit steel substrate 1 and the PDC cemented carbide segment 10 in sequence, and air dry for later use;

[0083] Step 2: Carry out laser etching treatment on the PDC cemented carbide section 10 air-dried in step 1. The method of carrying out laser etching treatment on the PDC cemented carbide section is: use laser to etch the peripheral surface of the PDC cemented carbide section into regular Or irregular striped lines 11 or reticular lines 12, the depth of the striped lines 11 and the reticular lines 12 is 0.05-1 mm, the line spacing is 1-4 mm, and the PDC cemented carbide segment after laser etching 10 Carry out electroless cobalt plating and electroplating nickel treatment successively, make PDC cemented carbide section form one d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com