Preparation method of asphalt-based carbon microsphere and application of asphalt-based carbon microsphere as sodium ion battery electrode material

A sodium-ion battery, carbon microsphere technology, applied in battery electrodes, carbon preparation/purification, negative electrodes, etc., can solve problems such as gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The raw material coal tar pitch was crushed, sieved, 10 g was added to 200 ml of high temperature resistant silicone oil, and 1 g of sodium dodecylbenzene sulfonate was added at the same time. At a stirring rate of 100 r / min, the system was heated up to 240° C. and kept for 2 hours. This process was always carried out in an air atmosphere. After the heat preservation is over, the pellets are separated from the silicone oil and washed. Put the product into a high-temperature carbonization furnace and heat it to 1200°C in a nitrogen atmosphere to obtain the final product.

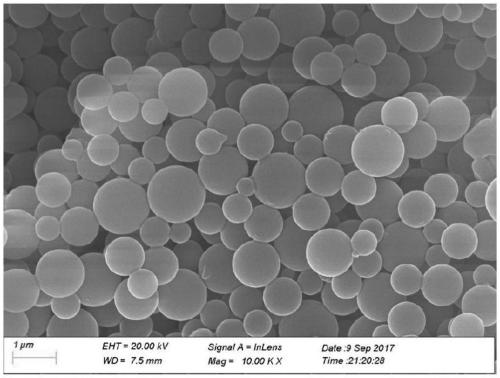

[0022] as attached figure 1 The morphology of pitch-based carbon microspheres shown by scanning electron microscopy (SEM) remained intact.

[0023] The electrode material at 0.05mA g -1 The discharge specific capacity under the current density can reach 265mA h g -1 ; at 1A g -1 The discharge specific capacity can still be maintained at 142mA h g at a high current density -1 .

Embodiment 2

[0025] The raw material petroleum asphalt was crushed, sieved, 10 g was added to 200 ml of high temperature resistant silicone oil, and 1 g of sodium dodecylbenzene sulfonate was added at the same time. At a stirring rate of 100 r / min, the system was heated up to 240° C. and kept for 2 hours. This process was always carried out in an air atmosphere. After the heat preservation is over, the pellets are separated from the silicone oil and washed. Put the product into a high-temperature carbonization furnace and heat it to 1200°C in a nitrogen atmosphere to obtain the final product.

[0026] Electrochemical performance test results show that the electrode material is -1 The discharge specific capacity under the current density can reach 312mA h g -1 ; at 1A g -1 The discharge specific capacity can still be maintained at 184mA h g at a high current density -1 .

Embodiment 3

[0028] Crush the raw coal tar pitch, sieve it, take 10g and add it to 200ml of high temperature resistant silicone oil, and add 1g of Span 80 at the same time. At a stirring rate of 100 r / min, the system was heated up to 240° C. and kept for 2 hours. This process was always carried out in an air atmosphere. After the heat preservation is over, the pellets are separated from the silicone oil and washed. Put the product into a high-temperature carbonization furnace and heat it to 1200°C in a nitrogen atmosphere to obtain the final product.

[0029] Electrochemical performance test results show that the electrode material is -1 The discharge specific capacity under the current density can reach 271mA h g -1 ; at 1A g -1 The discharge specific capacity can still be maintained at 144mA h g at a high current density -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

| Specific volume | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com