A kind of neodymium-doped scheelite structure negative temperature coefficient thermistor material and preparation method thereof

A technology of negative temperature coefficient and thermistor, applied to resistors with negative temperature coefficient, resistors, non-adjustable metal resistors, etc., can solve problems such as poor stability, narrow operating temperature range, and changes in electrical properties of materials , to achieve stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

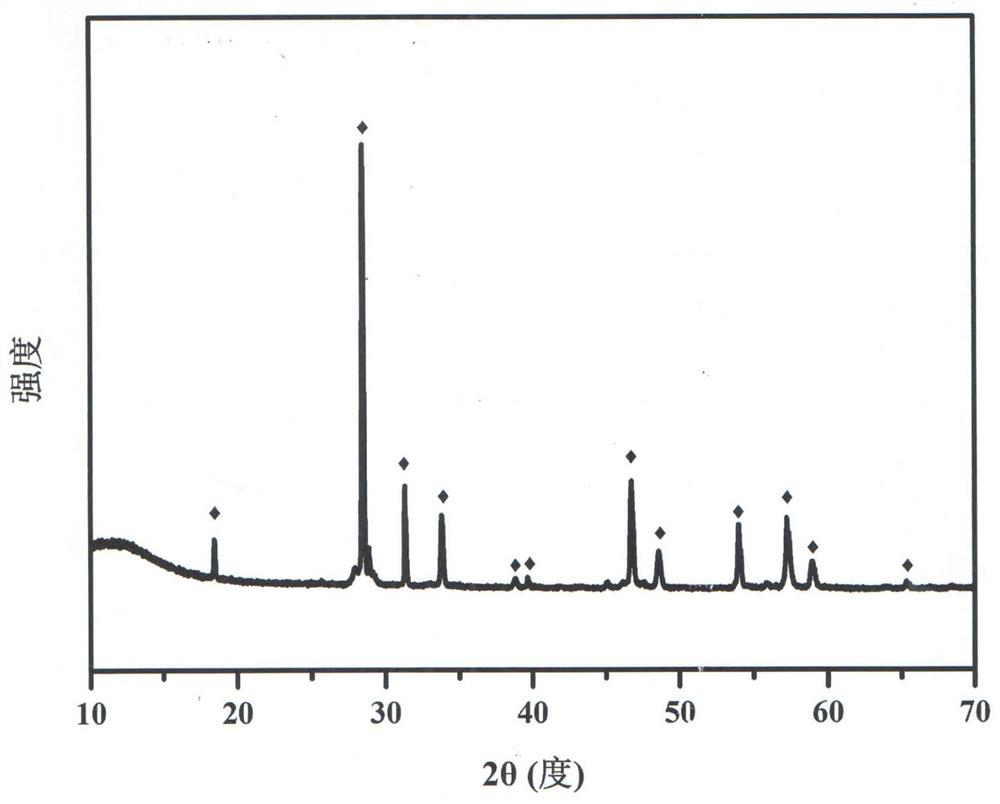

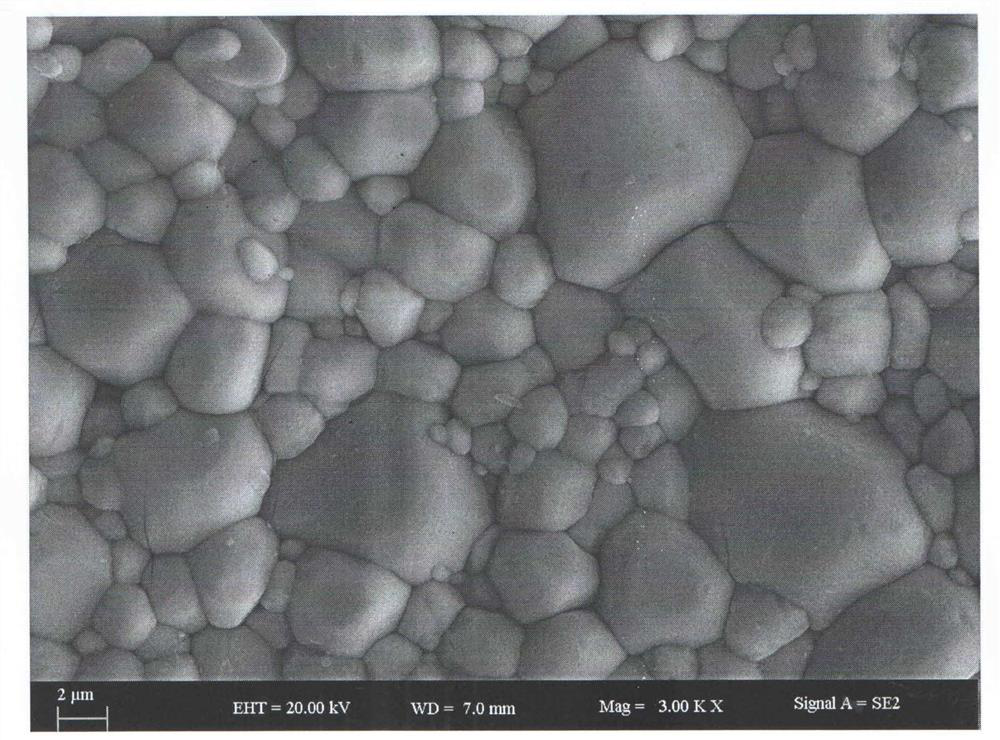

Image

Examples

Embodiment 1

[0019] a, with CaCO 3 , CeO 2 , Nb 2 o 5 、WO 3 and Nd 2 o 3 As a raw material, its chemical formula is CaCeNbWO 8 , molar ratio of raw material to CaCO 3 :CeO 2 :Nb 2 o 5 :WO 3 =0.4:0.4:0.2:0.4 weighed, placed in an agate mortar and ground for 6 hours, fully mixed uniformly to obtain a powder;

[0020] b. Calcining the powder obtained in step a at a temperature of 1100° C. for 3 hours, and then grinding for 4 hours. Repeat this process twice to obtain a thermistor powder;

[0021] c, the powder obtained in step b is 30Kg / cm 2 The pressure is briquetted for 1 minute, and the formed block is subjected to cold isostatic pressing, and the pressure is maintained at 200 MPa for 1 minute, and then the block is sintered at 1350 ° C for 3 hours to obtain a neodymium-doped scheelite structure. Calcium cerium niobium tungsten ceramic materials;

[0022] d. Coating the front and back sides of the ceramic material obtained in step c with platinum slurry electrodes, and then a...

Embodiment 2

[0025] a, with CaCO 3 , CeO 2 , Nb 2 o 5 、WO 3 and Nd 2 o 3 As raw material, its general chemical formula is Ca 0.9 Nd 0.1 CaB 8 , molar ratio of raw material to CaCO 3 :CeO 2 :Nb 2 o 5 :WO 3 :Nd 2 o 3=0.36:0.4:0.2:0.4:0.02 weighed, placed in an agate mortar and ground for 7 hours, fully mixed to obtain a powder;

[0026] b. Calcining the powder obtained in step a at a temperature of 1200° C. for 3 hours, and then grinding for 5 hours. Repeat this process twice to obtain a thermistor powder;

[0027] c, the thermistor powder that step b obtains with 40Kg / cm 2 The pressure is briquetted for 2 minutes, and the formed block is subjected to cold isostatic pressing, and the pressure is kept at 300 MPa for 2 minutes, and then the block is sintered at 1300 ° C for 6 hours to obtain a neodymium-doped scheelite structure. Calcium cerium niobium tungsten ceramic materials;

[0028] d. Coating the front and back sides of the ceramic material obtained in step c with plat...

Embodiment 3

[0031] a, with CaCO 3 , CeO 2 , Nb 2 o 5 、WO 3 and Nd 2 o 3 As raw material, its general chemical formula is Ca 0.8 Nd 0.2 CaB 8 , molar ratio of raw material to CaCO 3 :CeO 2 :Nb 2 o 5 :WO 3 :Nd 2 o 3 =0.32:0.4:0.2:0.4:0.04 weighed, placed in an agate mortar and ground for 7 hours, fully mixed to obtain a powder;

[0032] b. Calcining the powder obtained in step a at a temperature of 1200° C. for 4 hours, and then grinding for 6 hours. Repeat this process twice to obtain a thermistor powder;

[0033] c, the thermistor powder that step b obtains with 40Kg / cm 2 The pressure is briquetted for 2 minutes, the formed block is subjected to cold isostatic pressing, and the pressure is kept at 300 MPa for 3 minutes, and then the block is sintered at 1300 ° C for 9 hours to obtain a neodymium-doped scheelite structure Calcium cerium niobium tungsten ceramic materials;

[0034] d. Coat the front and back sides of the ceramic material obtained in step c with platinum pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com