Nuclear fuel cladding pipe and preparation method thereof

A cladding tube and nuclear fuel technology, applied in the direction of reactor fuel elements, nuclear engineering, nuclear power generation, etc., can solve the problems of increasing nuclear reactor operating costs, short service life, distortion and deformation, and achieve good neutron irradiation stability, suppression Oxidation, good thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In this embodiment, the nuclear fuel cladding tube is made of silicon carbide (SiC) and aluminum silicon carbon ceramic material (Al 4 SiC 4 ) composite material (Al 4 SiC 4 / SiC) composition, its preparation steps are as follows:

[0032] (1) Silicon carbide and precursor polycarbosilane (PCS) were cross-linked and cured at 600°C for 1 hour under an argon protective atmosphere to obtain PCS-600 powder.

[0033] (2) Mix an appropriate amount of PCS-600 powder and Al powder by ball milling, dry in vacuum, and crack at 1100°C for 2 hours under the protection of argon.

[0034] (3) The mixed powder obtained in step 2 is preformed into the shape of a nuclear fuel cladding tube, and then hot-pressed and sintered at 1700°C for 20 minutes to obtain Al 4 SiC 4 / SiC composite nuclear fuel cladding tube.

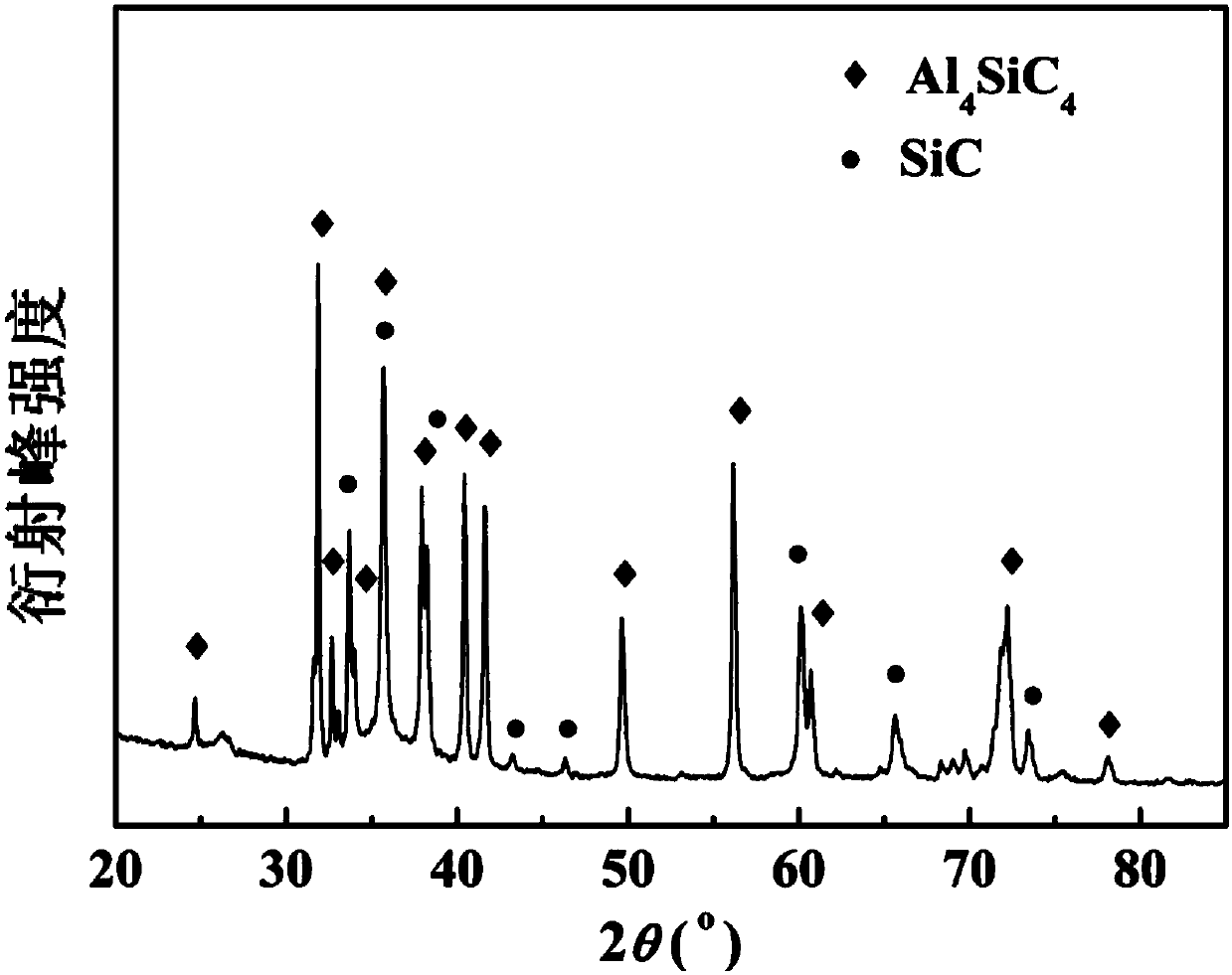

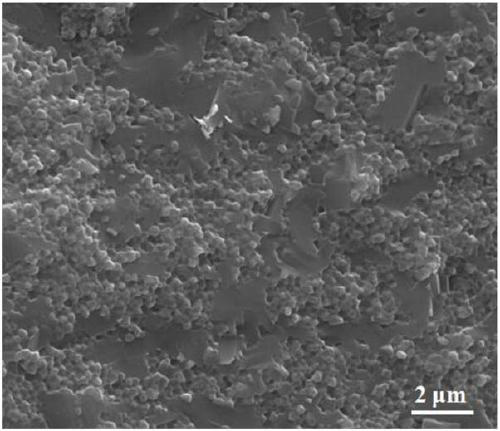

[0035] Such as figure 1 Shown is the Al prepared above 4 SiC 4 / SiC nuclear fuel cladding tube XRD pattern, it can be seen that the composite material is made of Al 4...

Embodiment 2

[0038] In this embodiment, the nuclear fuel cladding tube is made of silicon carbide (SiC) and aluminum silicon carbon ceramic material (Al 4 SiC 4 ) composite material Al 4 SiC 4 / SiC composition, Al 4 SiC 4 / SiC composite material is prepared by the reaction of liquid hyperbranched polycarbosilane (LHBPCS) and aluminum powder. The specific preparation steps are as follows:

[0039] (1) Mix LHBPCS with an appropriate amount of aluminum powder, and cure in vacuum at 100°C for 2 hours under the combined action of the initiator tert-butyl peroxybenzoate (TBPB);

[0040] (2) After grinding the block solidified in step 1 into powder, it is cracked at 1200° C. for 1 hour under an argon protective atmosphere;

[0041] (3) Preform the powder after pyrolysis in step 2 into the shape of a nuclear fuel cladding tube, and then undergo spark plasma sintering at 1600°C for 10 minutes to obtain Al 4 SiC 4 / SiC composite nuclear fuel cladding tube.

[0042] Al prepared above 4 SiC ...

Embodiment 3

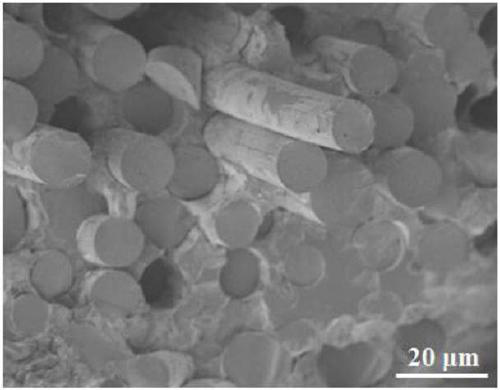

[0044] In this embodiment, the nuclear fuel cladding tube is silicon carbide fiber (SiC f ) and AlSiC ceramic material (Al 4 SiC 4 ) composite material Al 4 SiC 4 / SiC f Composition, its preparation steps are as follows:

[0045] (1) Mix liquid hyperbranched polycarbosilane (LHBPCS) with an appropriate amount of aluminum powder, disperse ultrasonically, and ball mill to make a slurry;

[0046] (2) According to the structure of the nuclear fuel cladding tube, the SiC f Pre-weaving into a tubular preform, impregnating the tubular preform with the slurry prepared in step 1 for 12 hours, while applying a pressure of 5 MPa;

[0047] (3) The impregnated SiC f Tubular preforms were pyrolyzed for 2 hours at 1600°C under an argon protective atmosphere;

[0048] (4) Repeat step (3) 5-10 times to obtain highly dense Al 4 SiC 4 / SiC f Constituted nuclear fuel cladding tube.

[0049] Al prepared above 4 SiC 4 / SiC f The phase composition and figure 1 similar, mainly by Al ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com