Pre-mixing type heat exchange commercial energy-saving and environment-friendly gas stove

An energy-saving and environment-friendly gas furnace technology, which is applied to heating fuel, household stove/stove, gaseous heating fuel, etc., can solve the problems of high cost, high cost of replacing artificial materials, and large maintenance volume, so as to reduce heat loss and save The effect of labor after-sales cost and pollutant emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

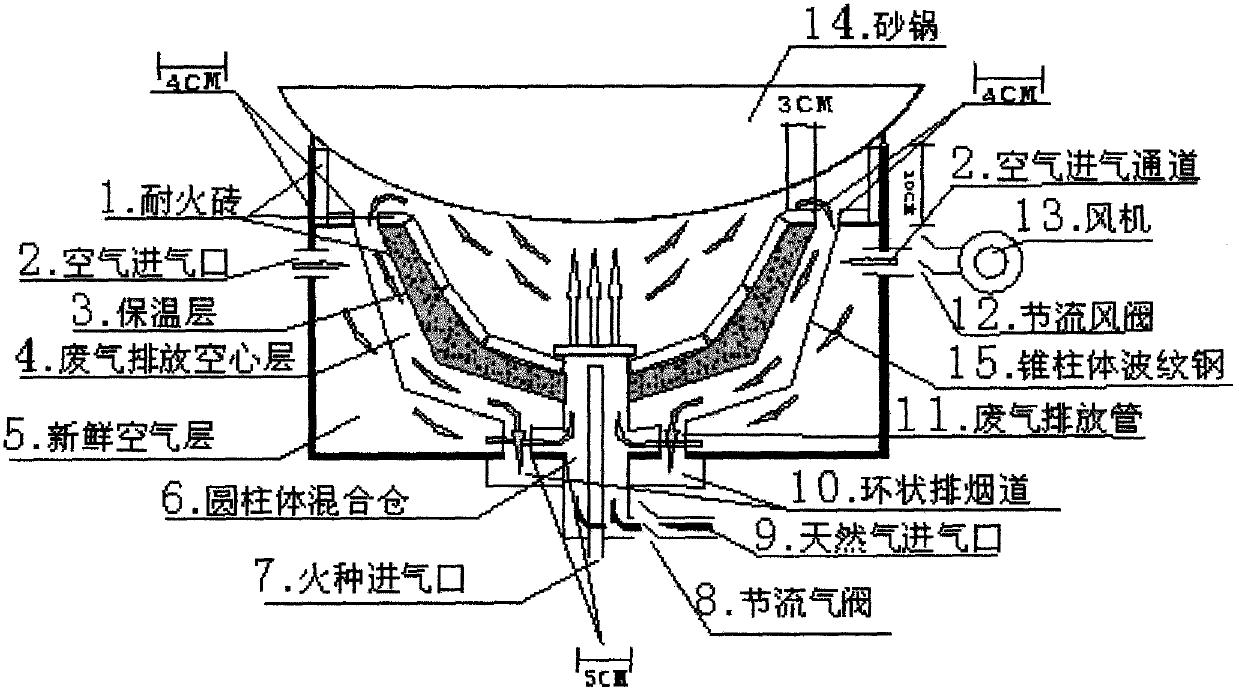

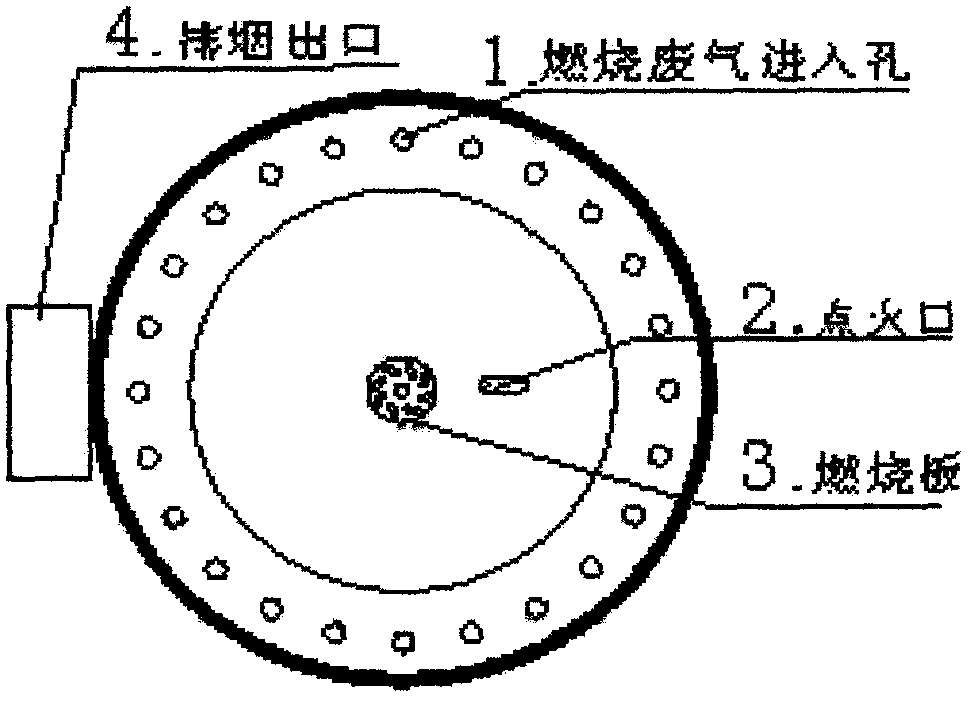

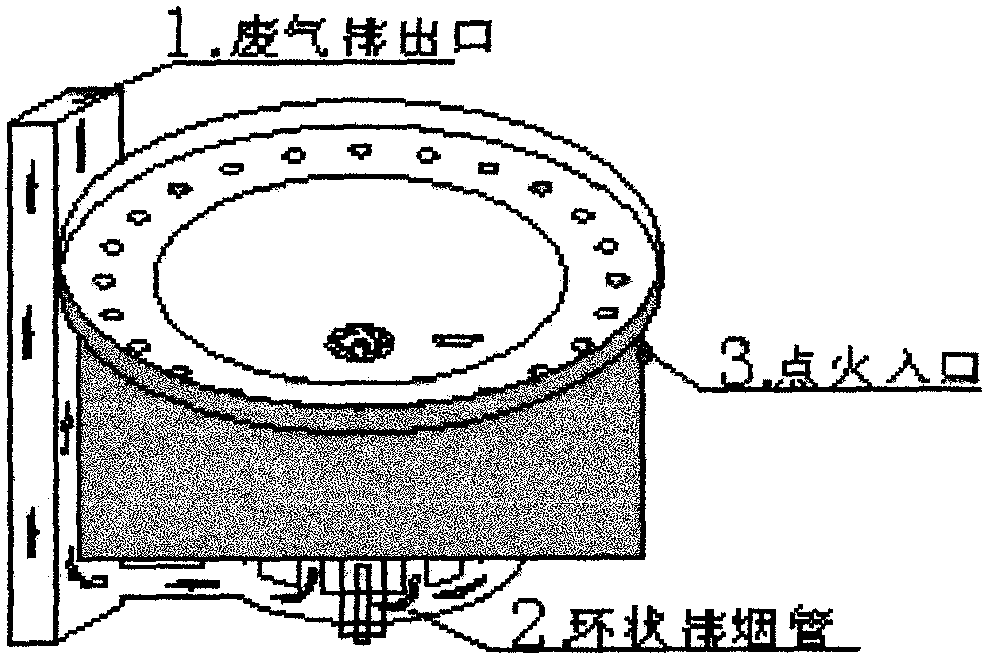

[0014] The present invention will be described in detail below in conjunction with the specific implementation examples of the accompanying drawings. A premixed heat exchange energy-saving and environment-friendly gas furnace is produced according to the blueprint design, such as figure 1 As shown in the sectional view: the first step is to make the outermost layer of this premixed heat exchange energy-saving and environmentally friendly figure 1 Medium 5 layers of fresh air, then with figure 1 The middle 6 cylindrical mixing bins are fixed, and the bottom of the fixed cylinder is connected with the figure 1 Cut 4cm high and obliquely through the slit hole above the middle 6 junction figure 1 In 6, the second step is with figure 1 The position 10 cm below the inner circle of the middle 14 in contact with the furnace body (with casserole not reaching figure 1 Middle 1 is suitable, and there is a certain gap for exhaust gas) to weld a 4cm wide annular plane, and then weld al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com