Quick-freeze oil-fried glutinous rice cake and industrial production method thereof

A production method and technology for glutinous rice cake, which are applied in the field of food processing, can solve the problems of high hardness of glutinous rice cake, insufficient crispness and limited outer layer, and achieve the effects of good water retention and frost crack resistance, which is beneficial to industrialized production and simplifies the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

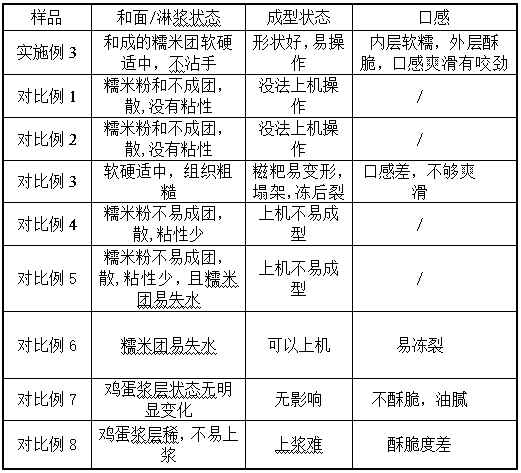

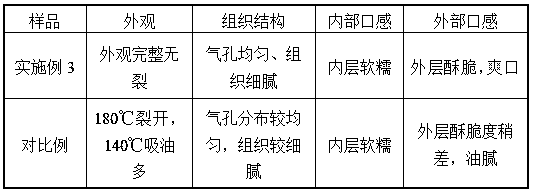

Examples

Embodiment 1

[0032] The embodiment of the present invention provides a quick-frozen fried glutinous rice cake, which comprises an inner main body of glutinous rice, a middle layer of egg syrup and an outer layer of bread crumbs.

[0033] The main body of glutinous rice and the bread crumb layer include the following raw materials in parts by weight: 98 parts of glutinous rice flour, 18 parts of white sugar powder, 10 parts of shortening, 4.5 parts of bread crumbs, 0.5 parts of rice cake improver, 0.5 parts of emulsified oil, and 60 parts of water. Copies. Wherein, the glutinous rice cake improver is composed of the following raw materials by weight: 30 parts of guar gum, 16 parts of hydrophilic monoglyceride, 18 parts of xanthan gum, 10 parts of soluble soybean polysaccharide, 4 parts of sodium polyacrylate, and tapioca starch 15 servings.

[0034] The egg slurry layer is mainly composed of the following raw materials by weight: 48 parts of egg liquid, 48 parts of white sugar powder, 12 parts ...

Embodiment 2

[0045] The embodiment of the present invention provides a quick-frozen fried glutinous rice cake, which has the same structure as the quick-frozen fried glutinous rice cake provided in Example 1. The composition of the raw materials is basically the same, and the main difference lies in the ratio of the raw materials. Specifically, in this embodiment, the main body of glutinous rice and the breadcrumb layer comprise the following raw materials by weight: 102 parts of glutinous rice flour, 22 parts of white sugar powder, 14 parts of shortening, 5.5 parts of bread crumbs, and 0.7 parts of glutinous rice cake improver , 0.7 parts of emulsified oil, 65 parts of water, wherein the glutinous rice cake modifier is composed of the following parts by weight of raw materials: 35 parts of guar gum, 20 parts of hydrophilic monoglyceride, 24 parts of xanthan gum, and 14 parts of soluble soybean polysaccharide Parts, 6 parts of sodium polyacrylate, 19 parts of tapioca starch. The egg slurry ...

Embodiment 3

[0048] The embodiment of the present invention provides a quick-frozen fried glutinous rice cake, which has the same structure as the quick-frozen fried glutinous rice cake provided in Example 1. The composition of the raw materials is basically the same, and the main difference lies in the ratio of the raw materials. Specifically, in this embodiment, the main body of glutinous rice and the breadcrumb layer comprise the following raw materials in parts by weight: 100 parts of glutinous rice flour, 20 parts of white sugar powder, 12 parts of shortening, 5 parts of bread crumbs, and 0.6 parts of glutinous rice flour improver , 0.6 parts of emulsified oil, 63 parts of water, wherein the glutinous rice cake modifier is composed of the following parts by weight of raw materials: 32 parts of guar gum, 18 parts of hydrophilic monoglyceride, 20 parts of xanthan gum, and 12 parts of soluble soybean polysaccharide Parts, 5 parts of sodium polyacrylate, 17 parts of tapioca starch. The egg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com