Thermoplastic organosilicon polyurethane elastomer material and preparation method thereof

A technology of polyurethane elastomer and silicone, which is applied in the field of polyurethane elastomer, can solve the problems of easy migration of silicone, and achieve the effects of improving various performances, high reactivity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

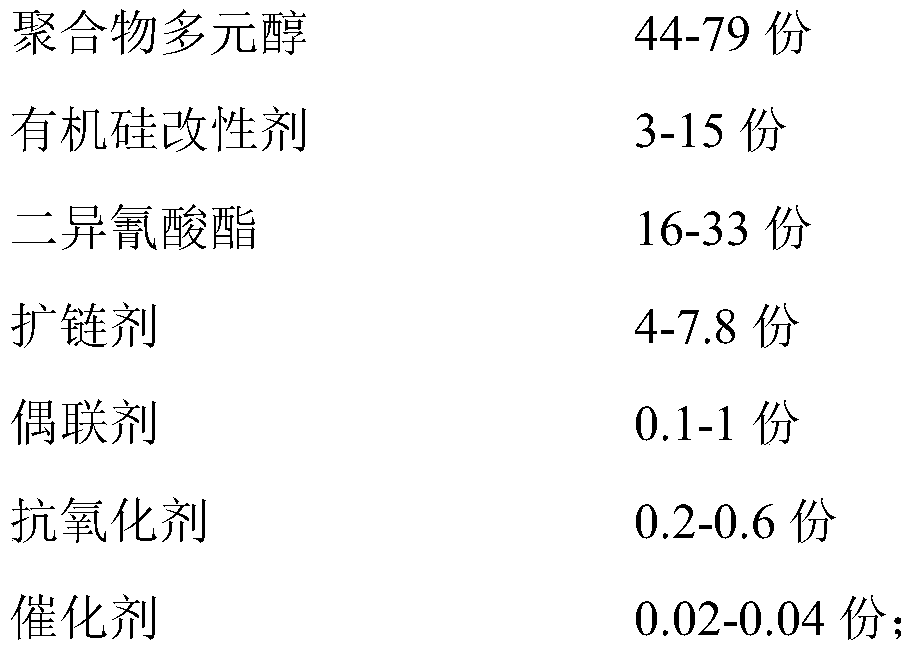

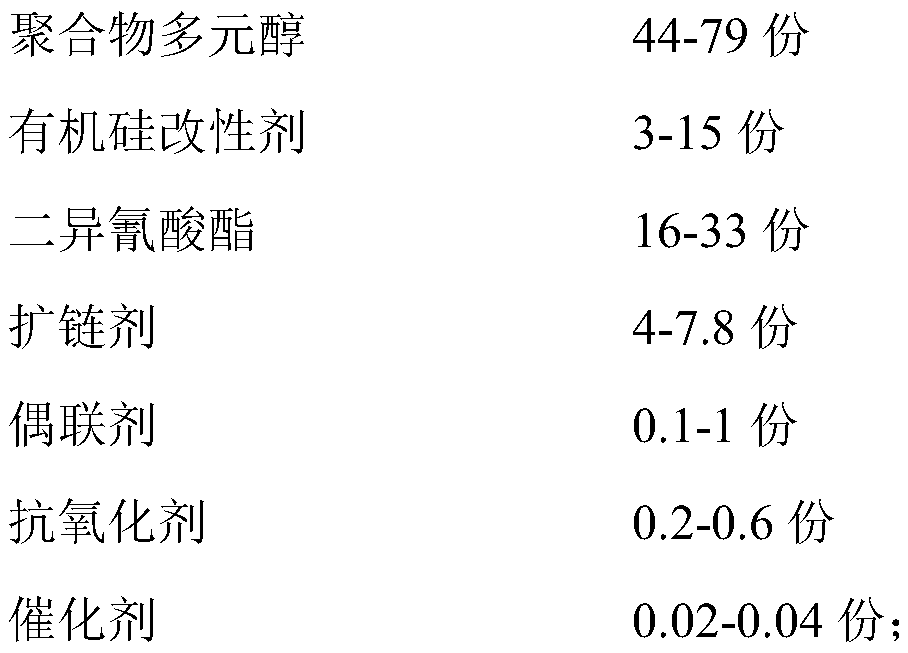

Method used

Image

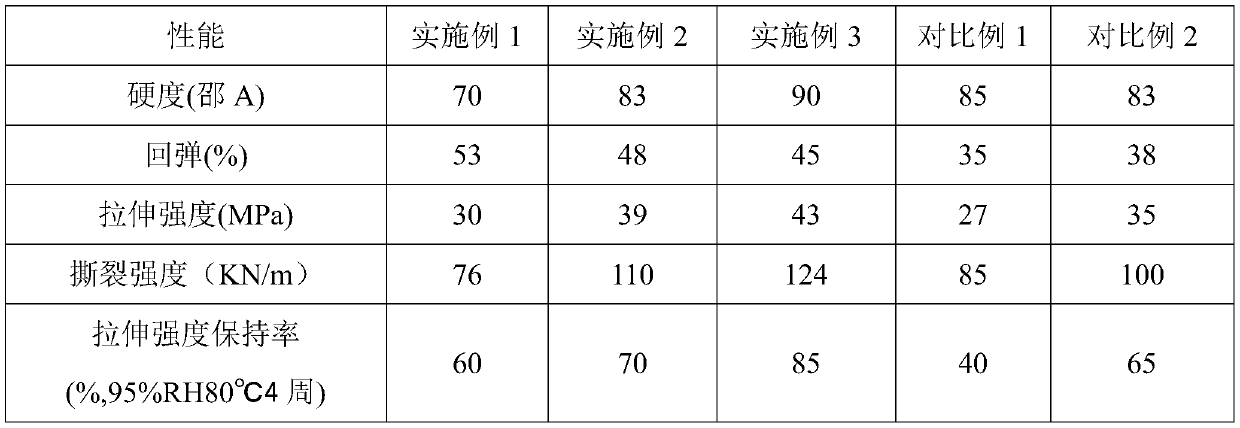

Examples

Embodiment 1

[0028] In terms of parts by mass, 78.85 parts of polyethylene adipate butylene glycol ester diol (PEBA, M=3000), 3 parts of single-ended difunctional group-terminated hydroxyalkylsiloxane-polyester compound (molecular weight 1000 , the siloxane content is 80%), 0.8 parts of silane coupling agent KH-550, 0.4 parts of main antioxidant 1076, 0.2 parts of auxiliary antioxidant 168, add in reactor A, keep the temperature at 100 ° C; 15.96 parts of MDI -100 was added to Reactor B, keeping the temperature at 70°C; 3.75 parts of 1,4-butanediol was added to Reactor C, keeping the temperature at 50°C; the isocyanate index was controlled at 1.005. After the temperature of each reactor is stabilized, the raw material components in Reactor A, Reactor B and Reactor C are mixed through a high-speed rotating mixing head through the infusion system with precise metering, and injected into the twin-screw extruder. Add 0.04 part of bismuth isooctanoate catalyst to the feeding port of the screw e...

Embodiment 2

[0030] In terms of parts by mass, 59.39 parts of polybutylene adipate diol (PBA, M=3000), 5 parts of double-ended difunctional group-terminated hydroxyalkylsiloxane-polyether compound (molecular weight 4000, silicone The alkane content is 95%), 0.5 parts of silane coupling agent KH-560, 0.2 parts of main antioxidant 1010, 0.2 parts of auxiliary antioxidant 168, add in reactor A, keep the temperature at 100 ° C; add 26.94 parts of MDI-100 In reactor B, keep the temperature at 70°C; add 7.74 parts of 1,4-butanediol into reactor C, keep the temperature at 50°C; control the isocyanate index at 1.005. After the temperature of each reactor is stabilized, the raw material components in Reactor A, Reactor B and Reactor C are mixed through a high-speed rotating mixing head through the infusion system with precise metering, and injected into the twin-screw extruder. 0.03 parts of bismuth neodecanoate catalyst is added to the feed port of the screw extruder through a micro-injection pump...

Embodiment 3

[0032]In terms of parts by mass, 44.58 parts of polytetramethylene ether glycol (PTMG, M=1000), 15 parts of double-ended difunctional group-terminated hydroxyalkylsiloxane-polyether compounds (molecular weight 2000, siloxane content 50%), 0.2 parts of silane coupling agent KH-560, 0.2 parts of primary antioxidant 1010, 0.1 part of auxiliary antioxidant DLTP, add to reactor A, keep the temperature at 100 ° C; add 32.61 parts of MDI-100 to the reactor In B, keep the temperature at 70°C; add 7.11 parts of 1,4-butanediol into reaction kettle C, keep the temperature at 50°C; control the isocyanate index at 1.005. After the temperature of each reactor is stabilized, the raw material components in Reactor A, Reactor B and Reactor C are mixed through a high-speed rotating mixing head through the infusion system with precise metering, and injected into the twin-screw extruder. Add 0.02 parts of bismuth laurate catalyst to the feeding port of the screw extruder through a micro-injection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com