Crystallizer and crystallization system

A crystallizer and crystallization technology, applied in the crystallizer and crystallization system, ammonia desulfurization process field, can solve the problems such as the inability to guarantee the clarity of the reflux slurry, the damage of the heater and the tube, and the small ammonium sulfate crystal particles. Complete crystallization effect, promote growth rate, and complete solid-liquid separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

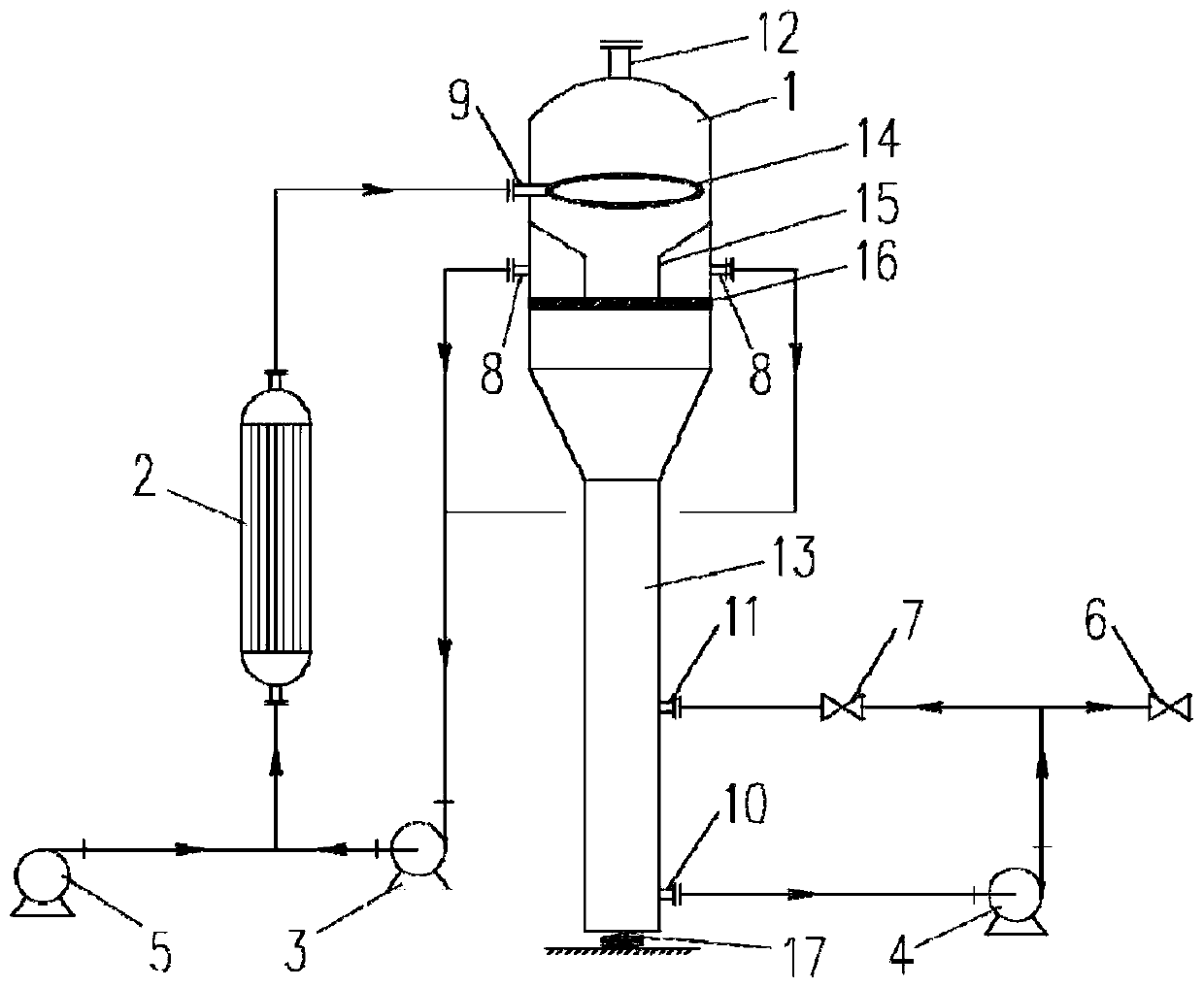

[0034] Such as figure 1 As shown, the crystallizer of this embodiment includes a crystallizer body 1, and the crystallizer body 1 is provided with a crystallizer inlet 9, a clarified liquid outlet 8, a crystallization slurry outlet 10, and a steam outlet 12. In a preferred solution, clarification There are two liquid outlets 8 arranged symmetrically;

[0035] A slurry distributor 14, a clarification zone and a crystal growth zone are arranged in the crystallizer body 1 along the flow direction of the slurry; the slurry distributor 14 is connected to the crystallizer inlet 9; the structure of the slurry distributor 14 can be an annular tube, and the tube A number of injection ports are evenly distributed along the circumferential direction,

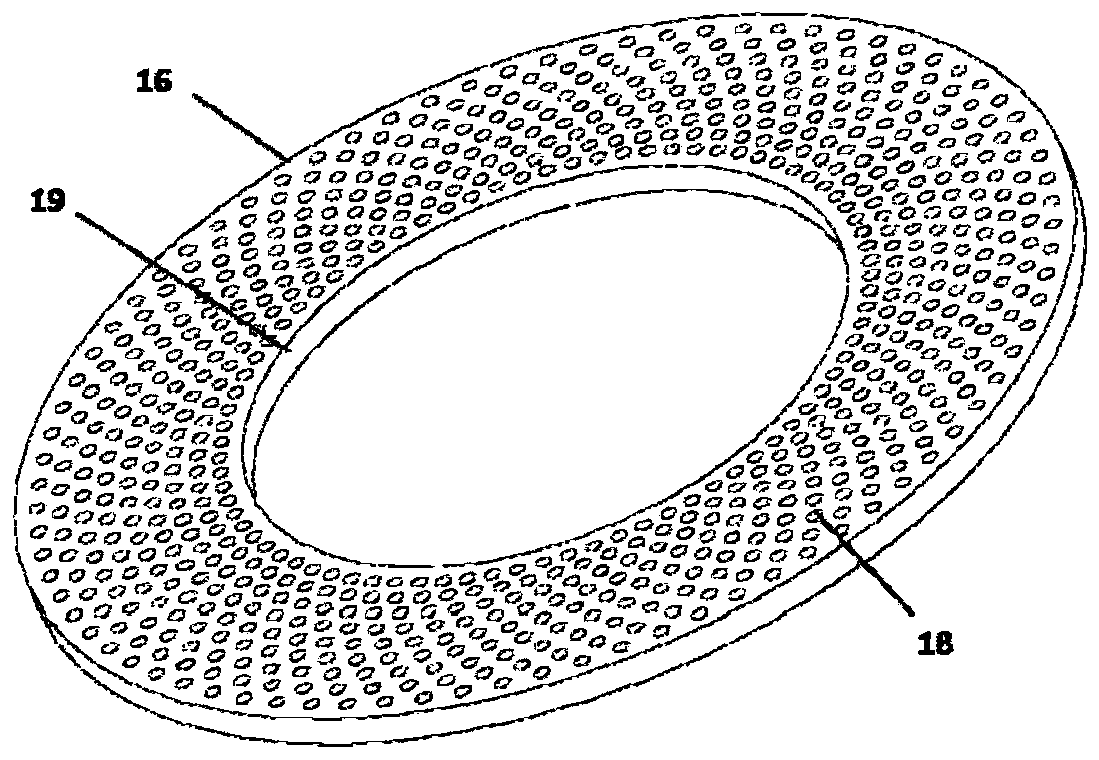

[0036] The clarified liquid outlet 8 is located in the clarification area, and the clarification area is equipped with a filter plate, such as figure 2 As shown, the diameter of the slurry through hole 19 accounts for 40% to 60% of the ...

Embodiment 2

[0045] Such as figure 1 , figure 2 As shown, the crystallization system of this embodiment further includes a heater 2 , an evaporation circulation pump 3 , an evaporation removal pump 4 and a thick slurry pump 5 on the basis of the above embodiments.

[0046] Optionally, the heater 2 is a shell-and-tube heat exchanger, and the heater 2 is connected to the thick slurry pump 5, the evaporation circulation pump 3, and the crystallizer inlet 9; the evaporation circulation pump 3 is connected to the thick slurry pump 5, the heater 2, and the clarifier Liquid outlet 8 connection;

[0047] When working, the original ammonium sulfate slurry from the thick slurry pump 5 is mixed with the clarified slurry from the evaporation circulation pump 3 and then enters the heater 2. The heater 2 is a shell-and-tube heat exchanger, and the heating heat comes from steam at about 180 ° C. After the ammonium sulfate slurry absorbs heat, the temperature rises to 105° C. to 110° C. to obtain the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com