System for purifying flue gas by using biomass adsorption material

A biomass adsorption and purification technology, applied in the fields of biofuel, gas treatment, other chemical processes, etc., can solve the problems of high cost, huge cost of flue gas treatment equipment, low energy consumption, etc., and achieve extended life and high industrial application value. , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

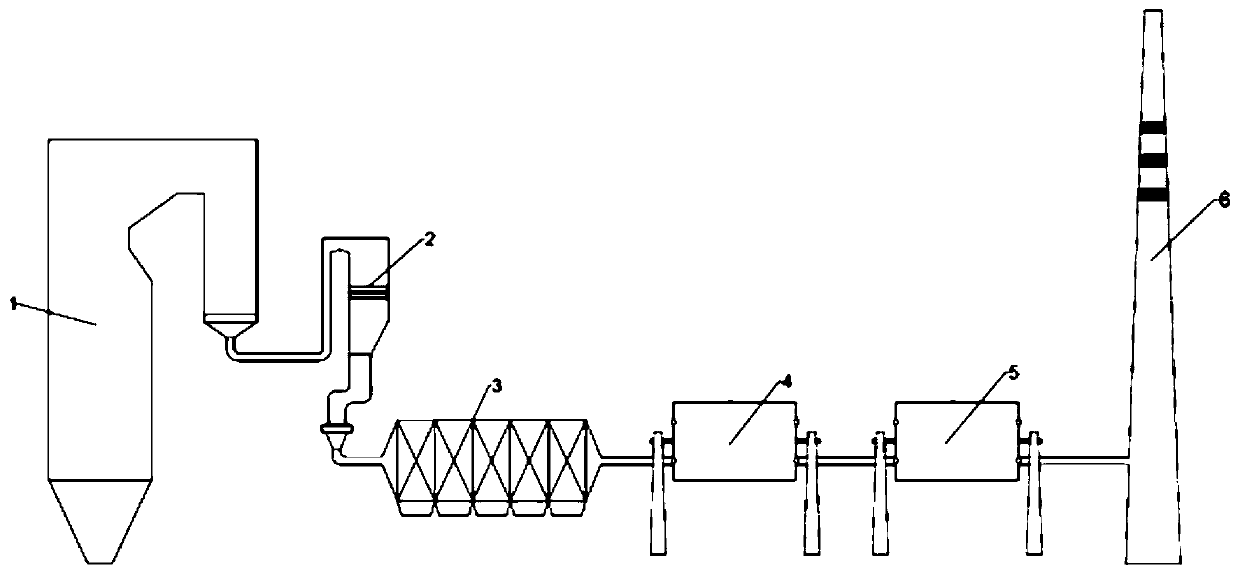

Embodiment 1

[0034] When treating the flue gas at the tail of the coal-fired power plant boiler, the tail flue gas generated by the power plant boiler is first passed into the SCR denitrification device, and the denitrification is carried out by using the catalytic effect of the denitrification biomass catalytic adsorption material; then the flue gas is passed into the dust removal device for particle removal. removal; then the flue gas is introduced into SO 2 In the removal module, the use of desulfurization biomass adsorption materials to adsorb SO 2 , and then introduce the desulfurized flue gas into the CO removal 2 In the removal module, CO is adsorbed by decarbonization biomass adsorption material 2 ; in the removal of SO 2 and CO 2 At the same time, the biomass adsorption material can also synergistically remove heavy metal elements such as mercury with very little stock; finally, the treated flue gas will be discharged into the atmosphere from the chimney.

[0035] Taking the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com