Composite phosphorus-based calcification inhibitor for inhibiting anaerobic granular sludge calcification and application method

An anaerobic granular sludge, composite phosphorus-based technology, applied in anaerobic digestion treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as calcification of granular sludge, and achieve simple and practical operation Strong, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

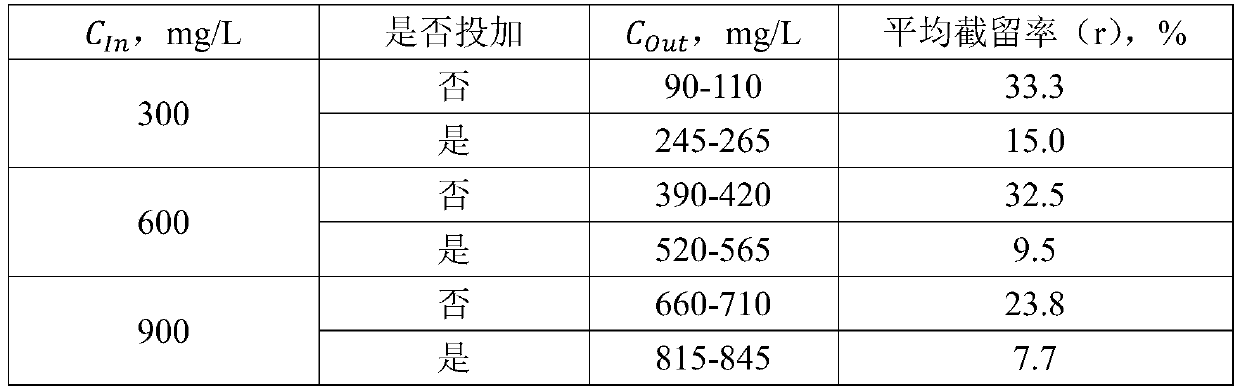

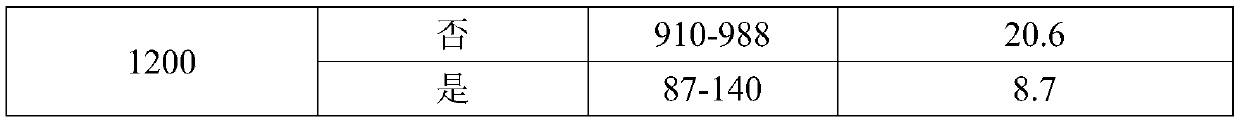

[0026] Embodiment 1: waste paper pulping wastewater treatment

[0027] 1) The typical wastewater quality of waste paper pulping is COD 1500-5000mg / L, Ca 2+ 300-1200mg / L, total phosphorus 0.5-2mg / L, pH value 6.2-7.5;

[0028] 2) Since the pH value of the wastewater is close to the suitable anaerobic pH value range, the compound phosphorus-based calcification inhibitor for blocking the calcification of anaerobic granular sludge in high-calcium wastewater needs to be close to neutral. The formula shown is as follows: 65 parts of phosphoric acid, 20 parts of sodium tripolyphosphate and 15 parts of sodium pyrophosphate were dissolved in water and mixed uniformly to obtain a 10wt% aqueous solution to obtain a composite phosphorus-based calcification inhibitor;

[0029] 3) According to the actual calcium ion concentration of the wastewater, calculate the dosage of the compound phosphorus-based calcification inhibitor per ton of water according to the calcium-phosphorus mass ratio o...

Embodiment 2

[0034] Embodiment 2: landfill leachate treatment

[0035] 1) Typical waste water quality of landfill leachate is COD 5000-20000mg / L, Ca 2+ 250-800mg / L, total phosphorus 5-25mg / L, ammonia nitrogen 400-1600mg / L, pH value 8.0-8.5;

[0036] 2) Since the pH value of the wastewater is alkaline and the concentration of ammonia nitrogen is high, free ammonia will be inhibited under alkaline conditions. Therefore, the compound phosphorus-based calcification inhibitor that blocks the calcification of anaerobic granular sludge in high-calcium wastewater needs to be acidic , the formula shown is as follows: 85 parts of phosphoric acid, 10 parts of sodium tripolyphosphate, 5 parts of sodium pyrophosphate, dissolved in water and mixed uniformly to obtain a 10wt% aqueous solution to obtain a composite phosphorus-based calcification inhibitor;

[0037] 3) According to the actual calcium ion concentration of the wastewater, calculate the dosage of the compound phosphorus-based calcification ...

Embodiment 3

[0041] Embodiment 3: fermentation wastewater treatment

[0042] 1) The typical wastewater quality of fermentation wastewater is COD 18000-40000mg / L, Ca 2+ 250-1000mg / L, total phosphorus 15-45mg / L, ammonia nitrogen 13000-16000mg / L, pH value 2.2-2.6;

[0043] 2) Since the pH value of the wastewater is acidic, the compound phosphorus-based calcification inhibitor that blocks the calcification of anaerobic granular sludge in high-calcium wastewater needs to be slightly alkaline. The formula shown is as follows: 40 parts of phosphoric acid, 25 parts of sodium tripolyphosphate 25 parts, sodium pyrophosphate, add water to dissolve and mix uniformly to obtain 10wt% aqueous solution, and make a composite phosphorus-based calcification inhibitor;

[0044] 3) According to the actual calcium ion concentration of the wastewater, calculate the dosage of the compound phosphorus-based calcification inhibitor per ton of water according to the mass calcium-phosphorus ratio of 25-35:1, and add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com