Compound and preparation method and application thereof

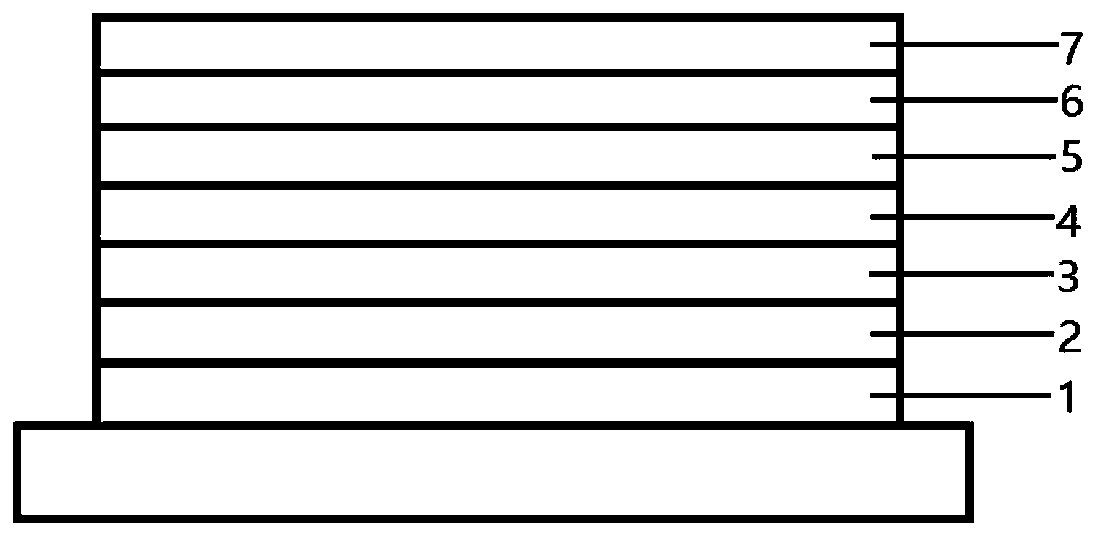

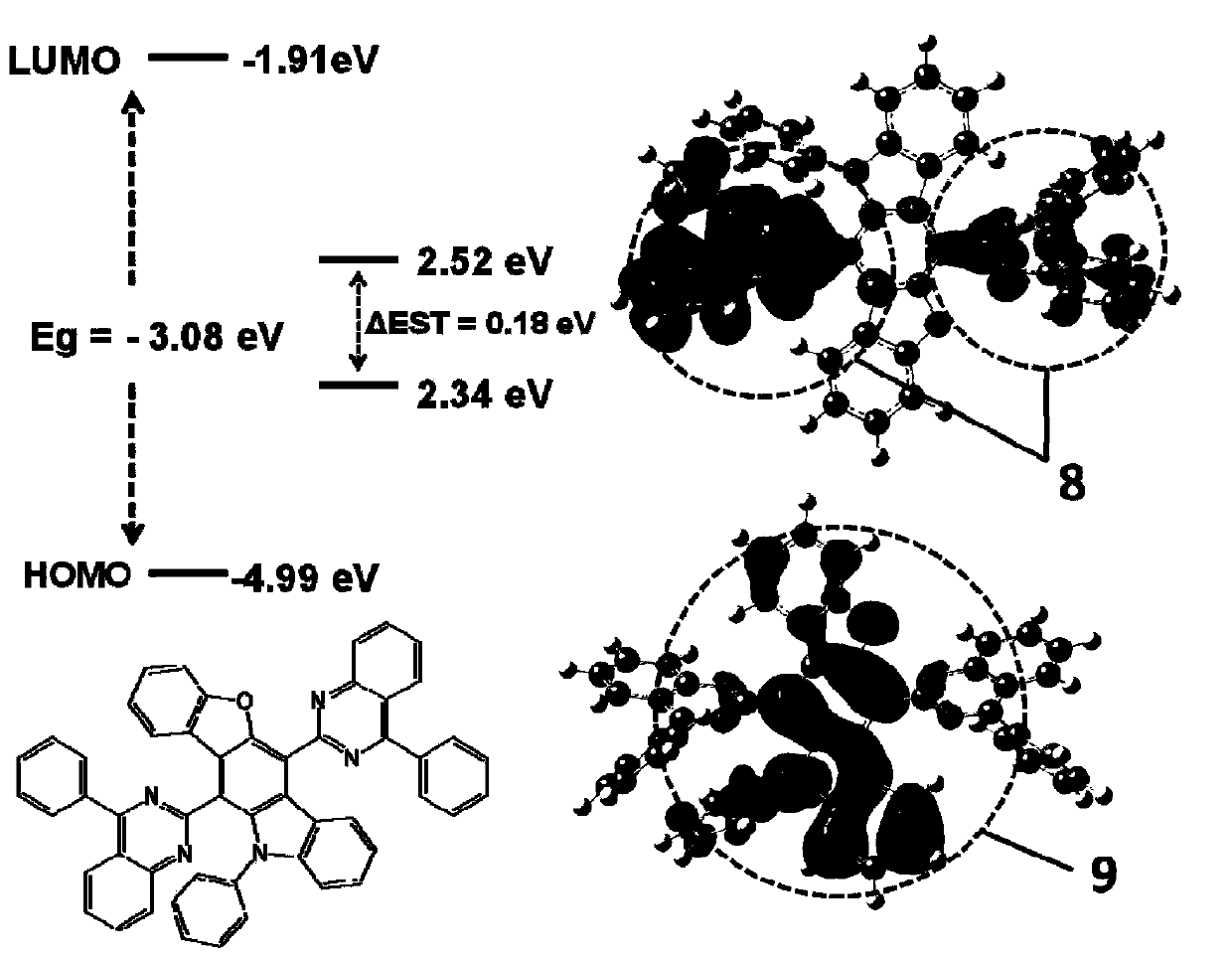

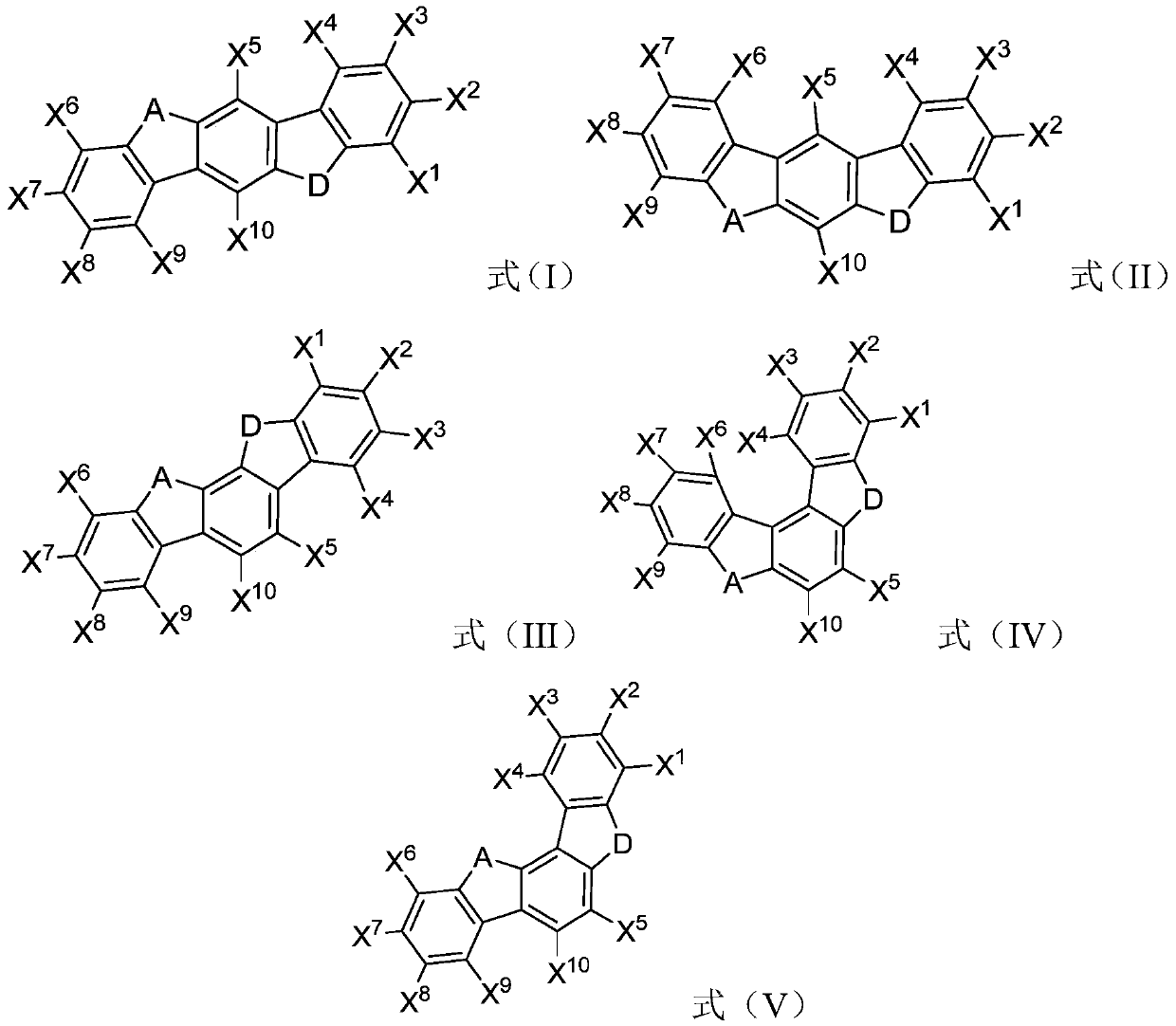

A compound and unsubstituted technology, applied in the field of compound and its preparation, can solve the problems of further improvement of current efficiency and high turn-on voltage, and achieve the effect of improving luminous efficiency and luminous performance, high glass transition temperature, and balanced injection and transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0100] This synthetic example provides a kind of synthetic method of compound, specifically as follows:

[0101]

[0102](1) Intermediate 1-1 synthesis steps: take 1000 milliliters of double-neck round bottom flasks and put them into a stirring bar and an upper connection reflux tube, fill with nitrogen after drying; first add compound 1-bromo-2-nitrobenzene ( 24.24 g, 1.2 eq), dibenzofuran-3-boronic acid (21.20 g, 1.0 eq), potassium carbonate (1.5 eq), ethanol (100 ml), water (100 ml), toluene (400 ml), tetra( Triphenylphosphine) palladium (0.5 equivalents), then heated to reflux and reacted for 12 hours, and cooled to room temperature after the reaction was completed. It was quenched by adding 200 mL of water and extracted with dichloromethane (3 x 400 mL). The resulting extract was dried by adding magnesium sulfate, filtered and spin-dried; the crude product was purified by chromatography (ethyl acetate / hexane, 1 / 10) to obtain intermediate 1-1 (20.23 g, yield 70% ).

...

Synthetic example 2

[0109] This synthetic example provides a kind of synthetic method of compound, specifically as follows:

[0110]

[0111] (1) Synthesis of intermediate 1-1: same as the synthesis of intermediate 1-1 in Synthesis Example 1;

[0112] (2) Synthesis of intermediate 2-1: same as the synthesis of intermediate 2-1 in Synthesis Example 1;

[0113] (3) Synthesis of intermediate 3-1: same as the synthesis of intermediate 3-1 in Synthesis Example 1;

[0114] (4) Synthesis of intermediate 4-2: take 500 milliliters of double-necked round-bottomed bottles and put them into a stirring bar and an upper connection reflux tube, fill with nitrogen after drying, and add intermediate 3-2 (41.51 grams, 1.0 eq. ), 2-boronic acid-4-phenylquinazoline (50.01 g, 2.0 equivalents), potassium carbonate (1.5 equivalents), ethanol (25 milliliters), water (25 milliliters), toluene (100 milliliters), tetrakis(triphenyl phosphine) palladium (0.5 equiv), and the mixture was refluxed for 12 hours. Cool to r...

Synthetic example 3

[0118] This synthetic example provides a kind of synthetic method of compound, specifically as follows:

[0119]

[0120] (1) Synthesis of intermediate 1-1: Synthesis with 1-1 in Synthesis Example 1;

[0121] (2) Synthesis of intermediate 2-1: Synthesis with 2-1 in Synthesis Example 1;

[0122] (3) Synthesis of intermediate 3-1: Synthesis with 3-1 in Synthesis Example 1;

[0123] (4) Synthesis of intermediate 4-3: take 500 milliliters of double-necked round-bottomed bottles and put them into a stirring bar and an upper connection reflux tube, fill with nitrogen after drying, and first add intermediate 3-1 (41.51 grams, 1.0 equivalent ), 3-(4-boronic acid phenyl)-dibenzofuran (57.6 g, 2.0 eq), potassium carbonate (1.5 eq), ethanol (25 ml), water (25 ml), toluene (100 ml), tetra (Triphenylphosphine)palladium (0.5 equiv), and the mixture was refluxed for 12 hours. Cool to room temperature after reaction. The reaction system was added with water, extracted with dichlorometh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com