Preparation method of self-repairing and anti-corrosion coating

An anti-corrosion coating and self-repairing technology, which is applied in anti-corrosion coatings, microsphere preparation, epoxy resin coatings, etc., can solve the problems of inability to combine functions, corrosion does not exist, etc., to improve compatibility and anti-corrosion function, improve the effect of greater rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

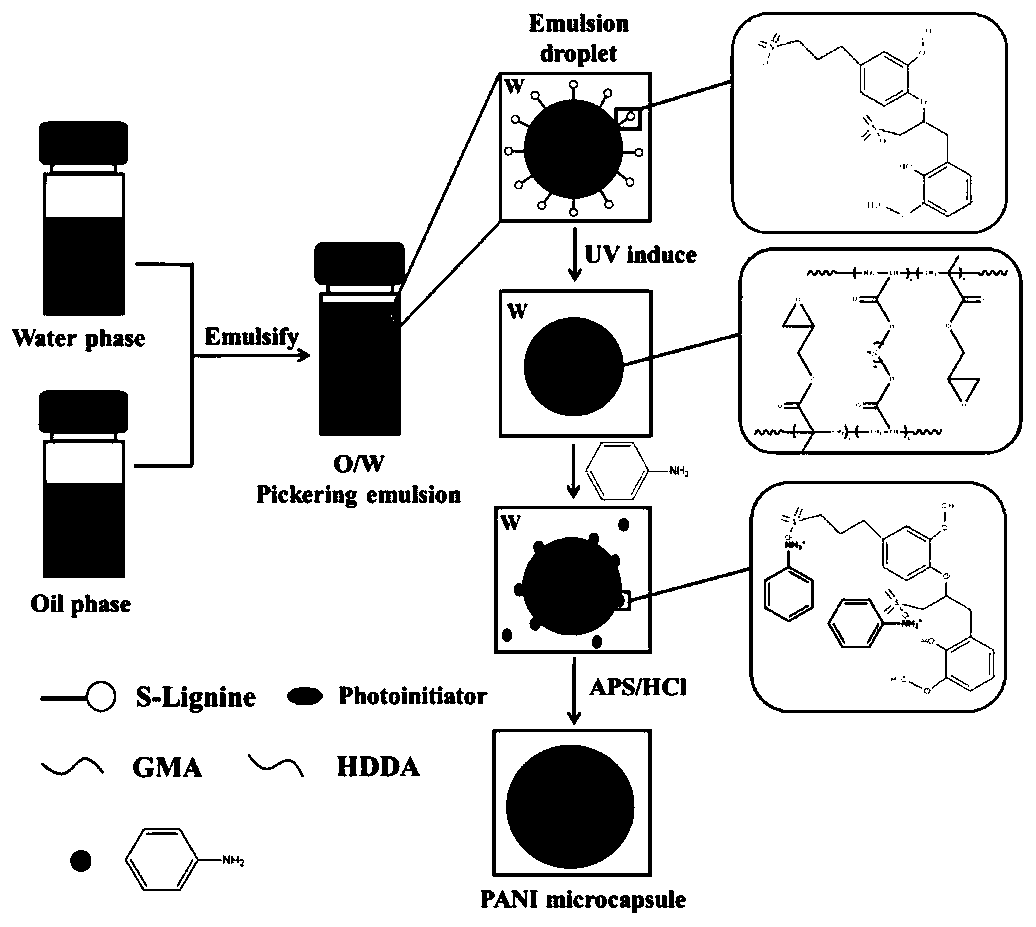

[0027] A preparation method of self-repairing and anti-corrosion coating based on polyaniline microcapsules, comprising the steps of:

[0028] (1) Dissolve 180 mg of calcium lignosulfonate in 6 mL of water as the aqueous phase by ultrasonication, and simultaneously add 0.96 mL of glycidyl methacrylate (GMA) (0.998 g, density: 1.040 g / mL), 0.24 mL of 1,6- Hexylene glycol acrylate (HDDA) (0.242g, density: 1.010g / mL), 24mg photoinitiator 369 (2% of the monomer mass), 4.2mL tung oil dissolved in 0.6mL toluene as the oil phase, according to the oil-water ratio Mix the two phases at 1:1, and emulsify for 2 minutes at 8000rpm with a high-speed disperser to form a stable oil-in-water (O / W) emulsion;

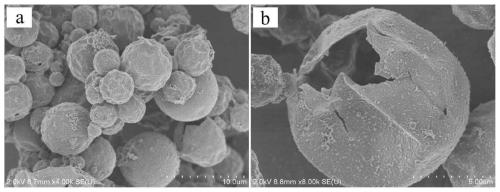

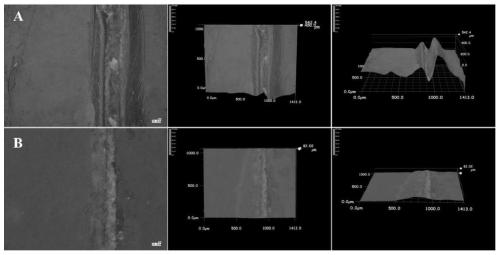

[0029] (2) Place the emulsion prepared in step (1) under ultraviolet light for 3 minutes to polymerize vinyl monomers, add 0.3 mL of aniline dropwise to the microcapsule dispersion after light, and then add 184 mg of ammonium persulfate ( The molar ratio of aniline is 1:4), 25 μL of hyd...

Embodiment 2

[0034] A preparation method of self-repairing and anti-corrosion coating based on polyaniline microcapsules, comprising the steps of:

[0035](1) Dissolve 480 mg of sodium dodecyl sulfonate in 12 mL of water as the aqueous phase by sonication, and simultaneously add 1.2 mL of dimethylaminoethyl methacrylate (DMAEMA) (1.119 g, density: 0.933 g / mL), 1.2 mL divinylbenzene (DVB) (1.102g, density: 0.919g / mL), 66.6mg photoinitiator 1173 (3% of monomer mass), 3mL hexamethylene diisocyanate (HDI) were dissolved in 0.6mL acetic acid in ethyl ester. Mix the two phases at an oil-to-water ratio of 1:2, and emulsify for 3 minutes at 9000 rpm through a high-speed disperser to form a stable oil-in-water (O / W) emulsion;

[0036] (2) Place the emulsion prepared in step (1) under ultraviolet light for 4 minutes to polymerize vinyl monomers, add 0.6 mL of aniline dropwise to the microcapsule dispersion after light, and then add 735 mg of ammonium persulfate ( The molar ratio of aniline is 1:2)...

Embodiment 3

[0039] A preparation method of self-repairing and anti-corrosion coating based on polyaniline microcapsules, comprising the steps of:

[0040] (1) Dissolve 1.2g of sodium polystyrene sulfonate in 24mL of water as the aqueous phase by ultrasonication, and simultaneously add 0.9mL of styrene (St) (0.827g, density: 0.909g / mL), 0.45mL of dipropylene glycol diacrylate (DPGDA) (0.472g, density: 1.05g / mL), 64.9mg azobisisobutyronitrile (AIBN) (5% of monomer mass), 3.6mL hexamethylene diisocyanate (HDI) dissolved in 1.05mL Dichloromethane, azobisisobutyronitrile. Mix the two phases at an oil-to-water ratio of 1:4, and emulsify for 5 minutes at 10,000 rpm through a high-speed disperser to form a stable oil-in-water (O / W) emulsion;

[0041] (2) Heat the emulsion prepared in step (1) to 70°C for 6 hours to polymerize the vinyl monomer, add 1.2mL of aniline dropwise to the microcapsule dispersion after light, and then add 2.94g of ammonium persulfate (Molar ratio to aniline is 1:1), 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com