Glass surface dust repelling film and preparation method thereof

A glass surface and thin film technology, applied in the direction of coating, etc., can solve the problems of insufficient stability of film electrical properties, poor stability of p-type ZnO material, high price, etc., to reduce the number of glass cleaning times, easy to coat large areas, and easy to control The effect of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of glass surface dust removal film and preparation method thereof, comprising the following steps: SnCl 2 2H 2 O, ethanol according to the molar ratio of 1:80, stirred at room temperature for 5h to prepare SnO 2 Sol, tetraethyl orthosilicate, ethanol, hydrochloric acid, deionized water according to the molar ratio of 1:16:8:0:0.1 was stirred at room temperature for 5h to prepare SiO 2 Sol. SiO 2 with SnO 2 The sol was mixed according to the molar ratio of 0.75 at room temperature for 4 hours, and aged for 24 hours to obtain SnO 2 / SiO 2 The sol was coated on the quartz glass plate by dipping for 60s at a pulling speed of 3000 μm / s. Heat the coated quartz glass substrate at 2°C / min to 350°C for 30 minutes, then heat at 8°C / min to 500°C for 1 hour to obtain SnO 2 / SiO 2 Dust removal film.

[0026] figure 1 It is the SnO obtained in Example 1 2 / SiO 2 Scanning Electron Microscope (SEM) picture of the dust-removing film. It can be seen from the picture th...

Embodiment 2

[0028] A kind of glass surface dust removal film and preparation method thereof, comprising the following steps: SnCl 2 2H 2 O, ethanol according to the molar ratio of 1:80, stirred at room temperature for 5h to prepare SnO 2 Sol, tetraethyl orthosilicate, ethanol, hydrochloric acid, deionized water according to the molar ratio of 1:16:8:0:0.1 was stirred at room temperature for 5h to prepare SiO 2 Sol. SiO 2 with SnO 2 The sol was mixed according to the molar ratio of 0.5 at room temperature for 4 hours, and aged for 24 hours to obtain SnO 2 / SiO 2The sol is coated on the quartz glass plate by the spin coating method with the spin coating speed a of 1000r / min and the time of 10s, and the speed b of 3000r / min and the time of 5s. Heat the coated quartz glass substrate at 2°C / min to 350°C for 30 minutes, then heat at 8°C / min to 450°C for 1 hour to obtain SnO 2 / SiO 2 Dust removal film.

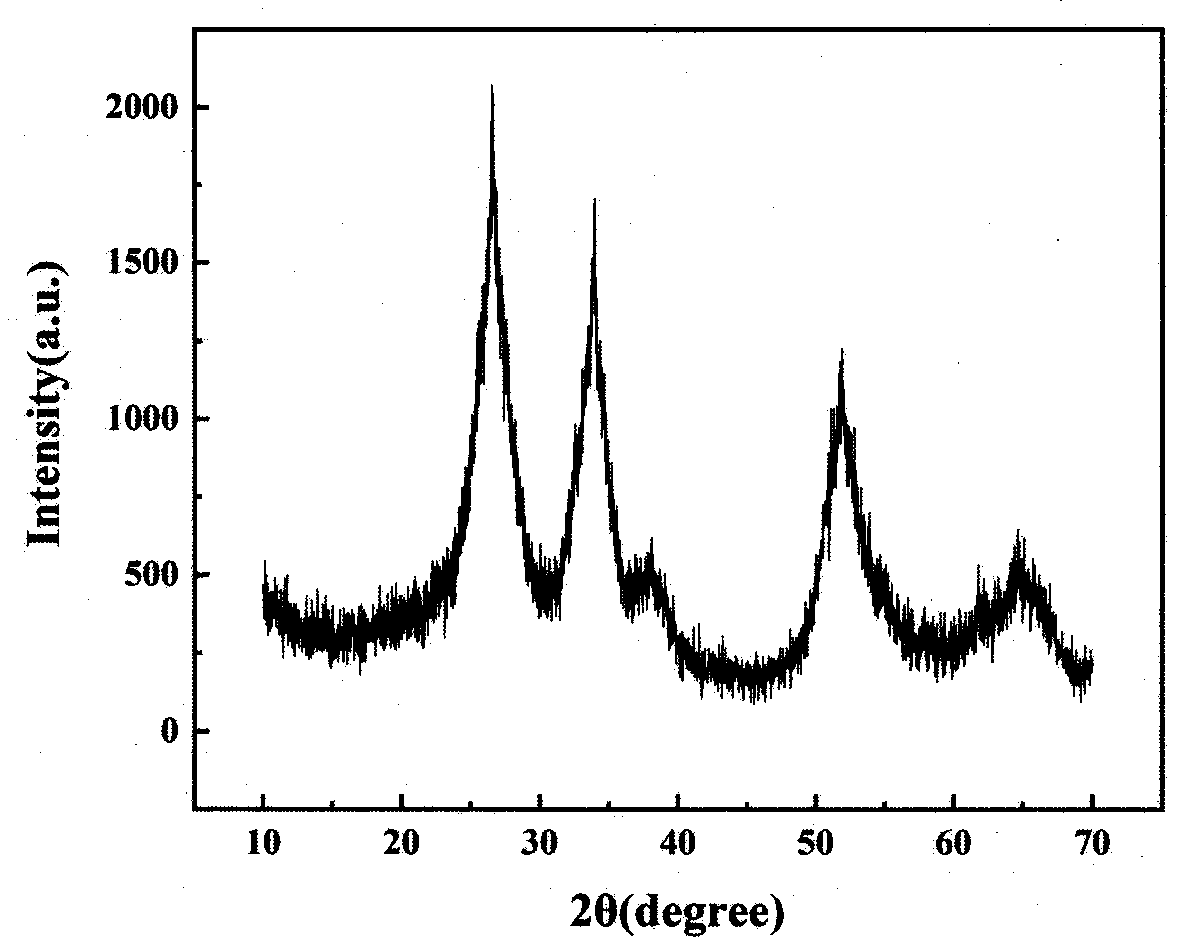

[0029] figure 2 It is the SnO obtained in Example 2 2 / SiO 2 X-ray diffraction ...

Embodiment 3

[0031] A kind of glass surface dust removal film and preparation method thereof, comprising the following steps: SnCl 2 2H 2 O, ethanol according to the molar ratio of 1:80 at room temperature for 3h to prepare SnO 2 Sol, tetraethyl orthosilicate, ethanol, hydrochloric acid, and deionized water were stirred at room temperature for 3 h in a molar ratio of 1:20:6:0:0.2 to prepare SiO 2 Sol. SiO 2 with SnO 2 The sol was mixed according to the molar ratio of 0.5 at room temperature for 2 hours, and aged for 24 hours to obtain SnO 2 / SiO 2 The sol is coated by the spraying method with an air pressure of 0.29Mpa, a distance of 20mm, a moving speed of 30cm / s, and a nozzle of 1.3mm to coat the quartz glass sheet. Heat the coated quartz glass substrate at 2°C / min to 350°C for 30 minutes, then heat at 8°C / min to 450°C for 1 hour to obtain SnO 2 / SiO 2 Dust removal film.

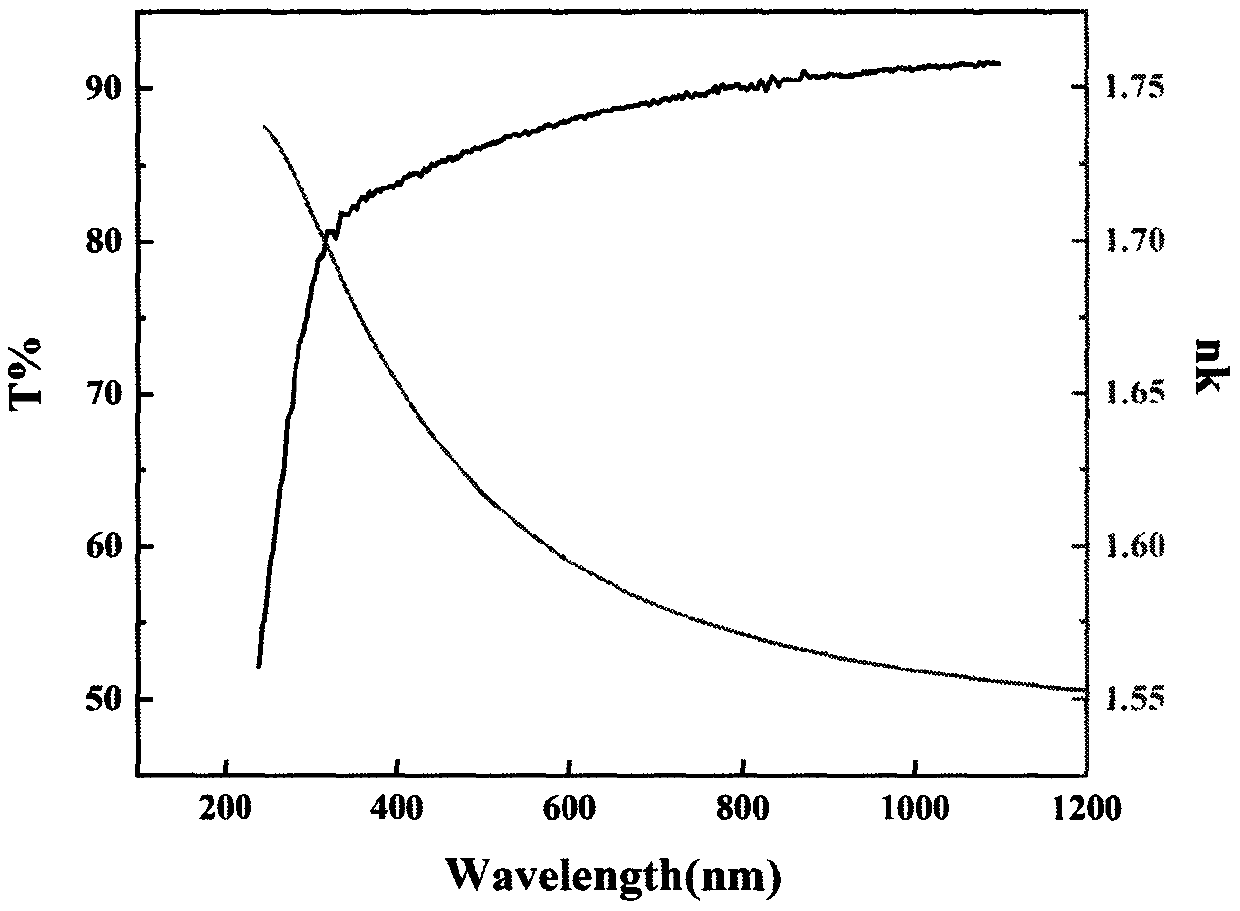

[0032] image 3 It is the SnO obtained in Example 3 2 / SiO 2 The visible light transmittance and refract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com