Preparation method and application of a comn-p-ncnt multifunctional catalyst

A comn-p-ncnt, multi-functional technology, applied in the field of CoMn-P-NCNT multi-functional catalyst and its preparation, can solve the problems limited to powder materials, poor activity, incomplete function, etc., to improve catalytic performance, The effect of complete functions and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 CoMn-NCNT multifunctional catalysts with different urea contents were prepared by the following method.

[0043] Preparation of precursors: 1.167 mmol of cobalt chloride, 2.333 mmol of manganese chloride, 7 mmol of ammonium fluoride, and the amount of urea was 14 mmol (the molar ratio of urea to metal salt was 4) and 17.5 mmol (the molar ratio of urea to metal salt was 4). ratio of 5), 21 mmol (the molar ratio of urea to metal salt is 6), and the concentration of dopamine hydrochloride is 20 mmol / L. Dissolve the above substances in a 100 mL beaker, add 70 mL of deionized water, and stir evenly. Put the carbon paper in the Teflon liner and pour the solution prepared above. After 10 hours of hydrothermal reaction at 100° C., washing and drying, the precursor was obtained.

[0044] Then, the above-prepared precursor and 14 g of urea were heated to 700 °C for 2 h at a heating rate of 5 °C / min to obtain the CoMn-NCNT multifunctional catalyst.

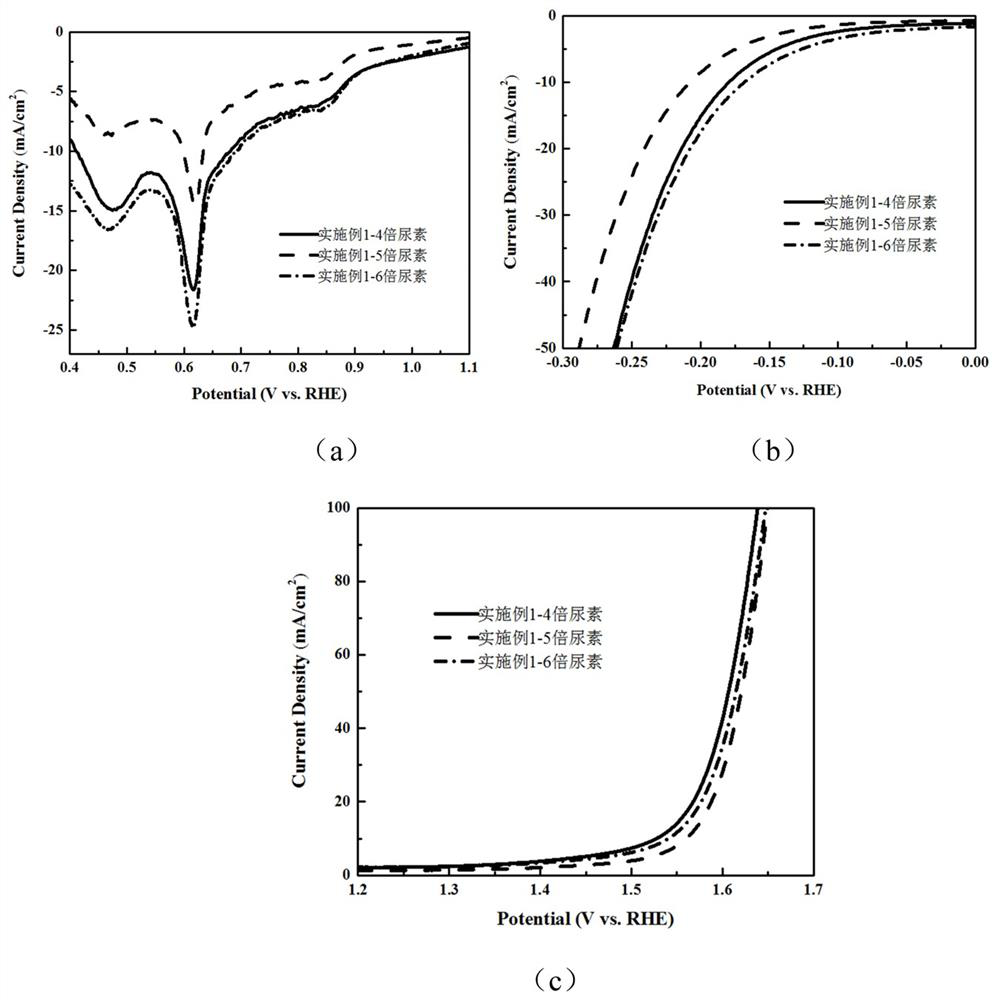

[0045] figure 1 I...

Embodiment 2

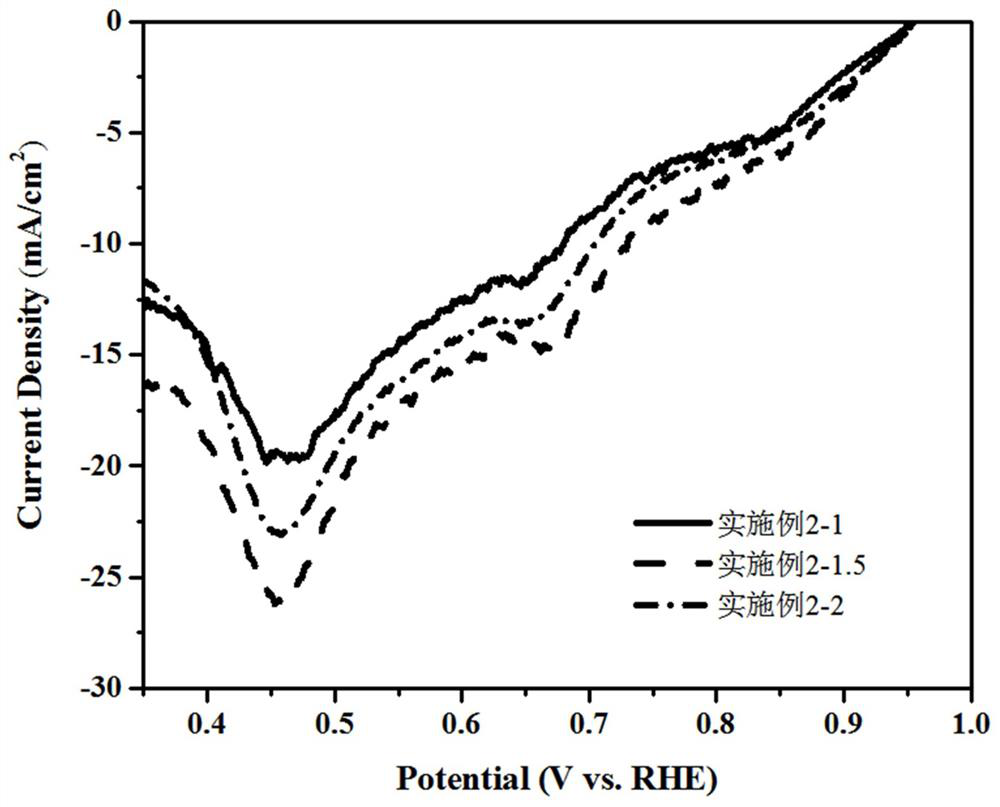

[0047] Example 2 CoMn-P-NCNT multifunctional catalysts with different sodium hypophosphite contents were prepared by the following method.

[0048] Preparation of precursors: 1.167 mmol of cobalt chloride, 2.333 mmol of manganese chloride, 7 mmol of ammonium fluoride, 21 mmol of urea, 20 mmol / L of dopamine hydrochloride in the mixed system, and 3.5 mmol of sodium hypophosphite ( Sodium hypophosphite is 1 times the amount of the metal salt substance), 5.25mmol (sodium hypophosphite is 1.5 times the amount of the metal salt substance), 7mmol (sodium hypophosphite is 2 times the amount of the metal salt substance, wherein the metal salt is The total amount of cobalt chloride and manganese chloride), dissolve the above substances in a 100 mL beaker, add 70 mL of deionized water, and stir evenly. Put the carbon paper in the Teflon liner and pour the solution prepared above. The hydrothermal reaction was carried out at 100°C for 10 hours. Wash, dry.

[0049] Then, the above-prepa...

Embodiment 3

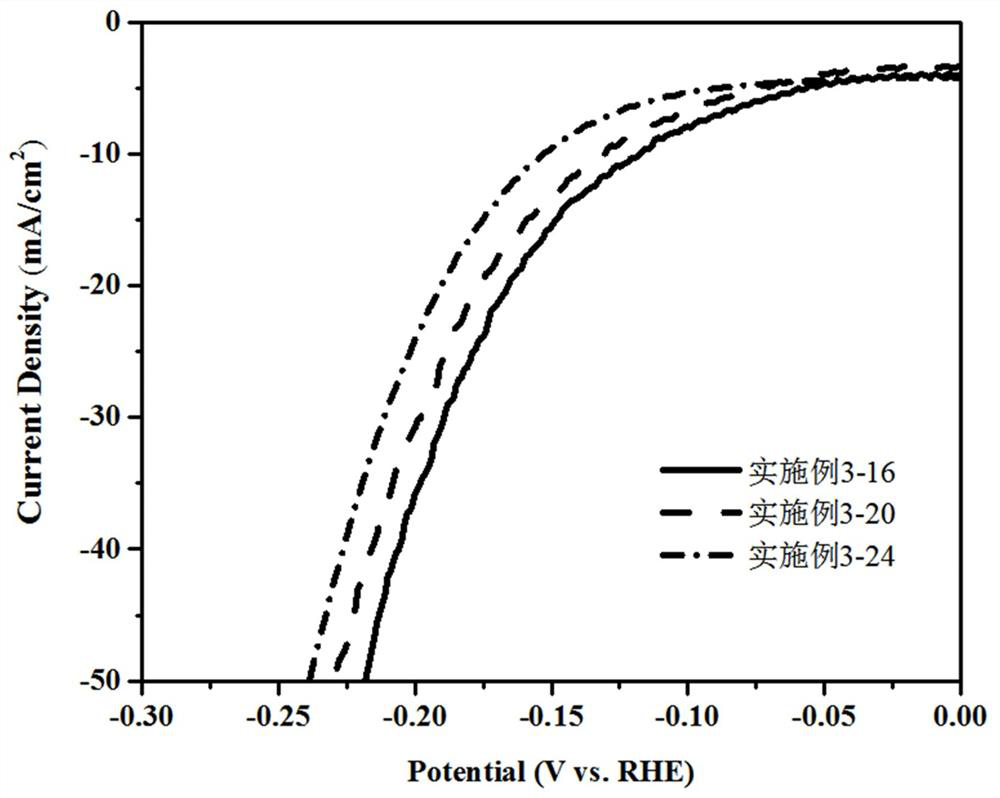

[0051] Example 3 CoMn-P-NCNT multifunctional catalysts with different contents of dopamine hydrochloride were prepared by the following method.

[0052] Preparation of precursor: cobalt chloride 1.167mmol, manganese chloride 2.333mmol, ammonium fluoride 7mmol, the amount of urea substance is 21mmol, the concentration of dopamine hydrochloride in the mixed system is (16mmol / L, 20mmol / L, 24mmol / L), the amount of phytic acid substance is 5.25mmol, dissolve the above substance in a 100mL beaker, add 70mL deionized water, and stir evenly. Put the carbon paper in the Teflon liner and pour the solution prepared above. The hydrothermal reaction was carried out at 100°C for 10 hours. Wash, dry.

[0053] Then, the above-prepared precursor and 14 g of urea were heated to 700 °C for 2 h at a heating rate of 5 °C / min, and then the CoMn-P-NCNT multifunctional catalyst was obtained.

[0054] image 3 It is the in-situ HER polarization curve diagram of the CoMn-P-NCNT multifunctional cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com