Shock absorption support composite material for high-cold, high-altitude and high-ultraviolet regions and preparation method thereof

A composite material and shock-absorbing support technology, which is applied in the field of shock-absorbing support composite materials and their preparation, can solve the problem that the composite material used for shock-absorbing support cannot meet the conditions of use, and achieves good comprehensive shock-absorbing effect and relatively high performance. Good capacitance and the effect of improving low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

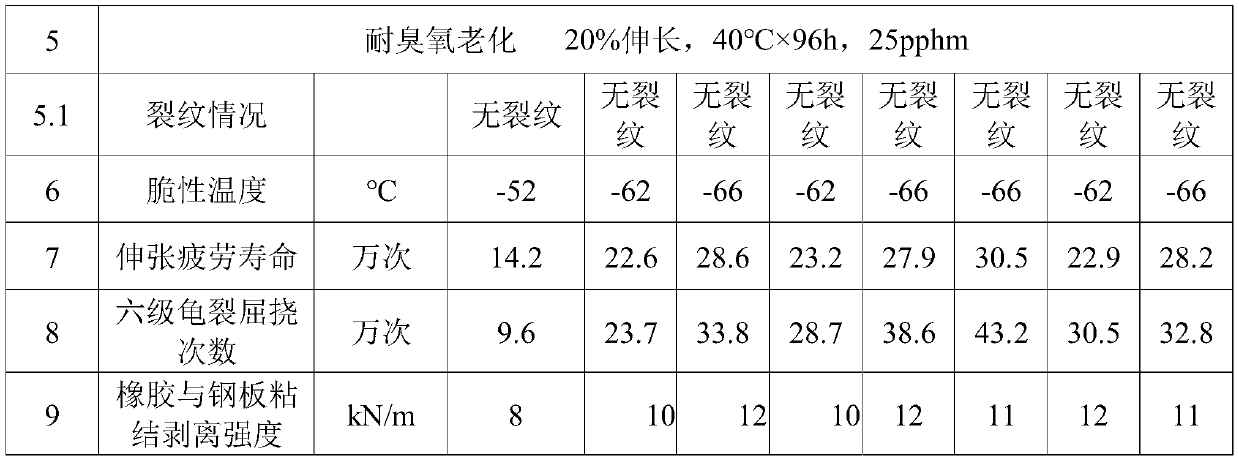

Examples

Embodiment 1

[0031] A shock-absorbing bearing composite material formula 1 for high-cold, high-altitude, and high-ultraviolet regions:

[0032] Including the following components by weight: 100 parts of natural rubber, 10 parts of liquid farnesene polymer, 10 parts of liquid polybutadiene, 10 parts of trans-polyisoprene, 50 parts of carbon black N330, 8 parts of nano titanium dioxide parts, 2 parts of microcrystalline wax, 40202 parts of anti-aging agent, 2 parts of anti-ultraviolet agent C81, 5 parts of tackifying resin, 2 parts of C5 petroleum resin, 10 parts of 3mm long chopped carbon fiber, 5 parts of zinc oxide, 1 part of stearic acid parts, 2.5 parts of sulfur, and 1.2 parts of N-cyclohexyl-2-benzothiazole sulfenamide.

[0033] A preparation method of a shock-absorbing support composite material in a high-cold, high-altitude, and high-ultraviolet region, comprising the following steps:

[0034] Weigh 100 parts of masticated natural rubber, 10 parts of liquid farnesene polymer, 10 pa...

Embodiment 2

[0037] A shock-absorbing bearing composite material formula 2 for high-cold, high-altitude, and high-ultraviolet regions:

[0038] Including the following components by weight: 100 parts of natural rubber, 20 parts of liquid farnesene polymer, 10 parts of liquid polybutadiene, 10 parts of trans-polyisoprene, 50 parts of carbon black N330, 8 parts of nano titanium dioxide parts, 2 parts of microcrystalline wax, 40202 parts of anti-aging agent, 2 parts of anti-ultraviolet agent C81, 5 parts of tackifying resin, 2 parts of C5 petroleum resin, 10 parts of 3mm long chopped carbon fiber, 5 parts of zinc oxide, 1 part of stearic acid parts, 2.5 parts of sulfur, and 1.2 parts of N-cyclohexyl-2-benzothiazole sulfenamide.

[0039] A preparation method of a shock-absorbing support composite material in a high-cold, high-altitude, and high-ultraviolet region, comprising the following steps:

[0040] Weigh 100 parts of masticated natural rubber, 20 parts of liquid farnesene polymer, 10 pa...

Embodiment 3

[0043] A shock-absorbing bearing composite material formula 3 for high-cold, high-altitude and high-ultraviolet regions:

[0044] Including the following components by weight: 100 parts of natural rubber, 10 parts of liquid farnesene / butadiene copolymer, 10 parts of liquid polybutadiene, 10 parts of trans-polyisoprene, 50 parts of carbon black N330 , 8 parts of nano titanium dioxide, 2 parts of microcrystalline wax, 2 parts of anti-aging agent 4020, 2 parts of anti-ultraviolet agent C81, 5 parts of tackifier resin, 2 parts of C5 petroleum resin, 10 parts of 3mm long chopped carbon fiber, 5 parts of zinc oxide , 1 part of stearic acid, 2.5 parts of sulfur, and 1.2 parts of N-cyclohexyl-2-benzothiazole sulfenamide.

[0045] A preparation method of a shock-absorbing support composite material in a high-cold, high-altitude, and high-ultraviolet region, comprising the following steps:

[0046] Weigh 100 parts of masticated natural rubber, 10 parts of liquid farnesene / butadiene cop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com