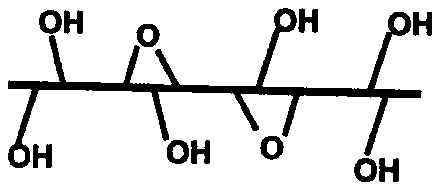

Microwave reduction preparation method of hydroxylated graphene coated atomic force microscope probe

A hydroxylated graphene, atomic force microscope technology, applied in scanning probe technology, scanning probe microscopy, measuring devices and other directions, can solve the problems of many impurities coated on the tip of the needle, cannot be prepared on a large scale, and high production costs, and achieves Avoid contamination, extend service life, reduce the effect of rapid wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

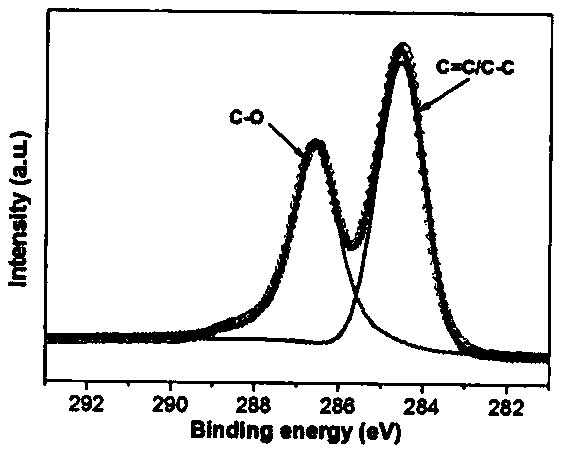

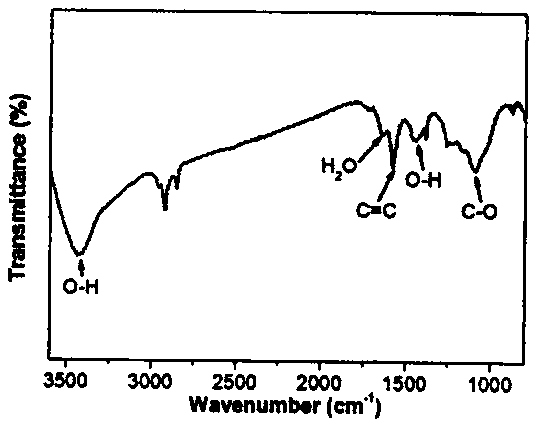

Method used

Image

Examples

Embodiment 1

[0029] (1) 0.3g anhydrous FeCl 3 Mix evenly with 0.05g of expanded graphite, vacuum-tightly seal it in a 20mL vacuum ampoule, raise the temperature to 380°C in 1h, and maintain it for 12h. The black product was dissolved in dilute hydrochloric acid solution, filtered and dried for use.

[0030] (2) Take out the intercalation compound, disperse it in 50mL organic solvent N-methylpyrrolidone, prepare a 5mg / mL suspension, add 10mL sodium borohydride alkaline aqueous solution to the container, and ultrasonically react for 1h to obtain a graphene material , wash and set aside.

[0031] (3) 20mL H 2 SO 4 Maintained in ice water (0° C.) for 0.5 h, added 30 mg of the original graphene material into concentrated sulfuric acid, and stirred for 10 min.

[0032] (4) Put 120 mg of sodium chlorate into a solution of concentrated sulfuric acid and graphene, stir at room temperature for 4 hours, and repeat centrifugal washing and drying of the product.

[0033] (5) Put the hydroxylated g...

Embodiment 2

[0037] (1) 0.3g anhydrous FeCl 3 Mix evenly with 0.05g of expanded graphite, vacuum-tightly seal it in a 20mL vacuum ampoule, raise the temperature to 380°C in 1h, and maintain it for 12h. The black product was dissolved in dilute hydrochloric acid solution, filtered and dried for use.

[0038] (2) Take out the intercalation compound, disperse it in 50mL organic solvent N-methylpyrrolidone, prepare a 5mg / mL suspension, add 10mL sodium borohydride alkaline aqueous solution to the container, and ultrasonically react for 1h to obtain a graphene material , wash and set aside.

[0039] (3) 20mL H 2 SO 4 Maintained in ice water (0° C.) for 0.5 h, added 30 mg of the original graphene material into concentrated sulfuric acid, and stirred for 10 min.

[0040] (4) Put 120 mg of sodium chlorate into a solution of concentrated sulfuric acid and graphene, stir at room temperature for 4 hours, and repeat centrifugal washing and drying of the product.

[0041] (5) Put the hydroxylated g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com