Solar cell absorption layer and preparation method and application thereof

A technology for solar cells and absorbing layers, applied in the field of solar cells, can solve problems such as uneven film composition, difficult-to-sulfur antimony selenide film, and poor crystallinity of the film, and achieve easy control of film composition and thickness, and simple preparation equipment and processes , The uniformity of the film is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

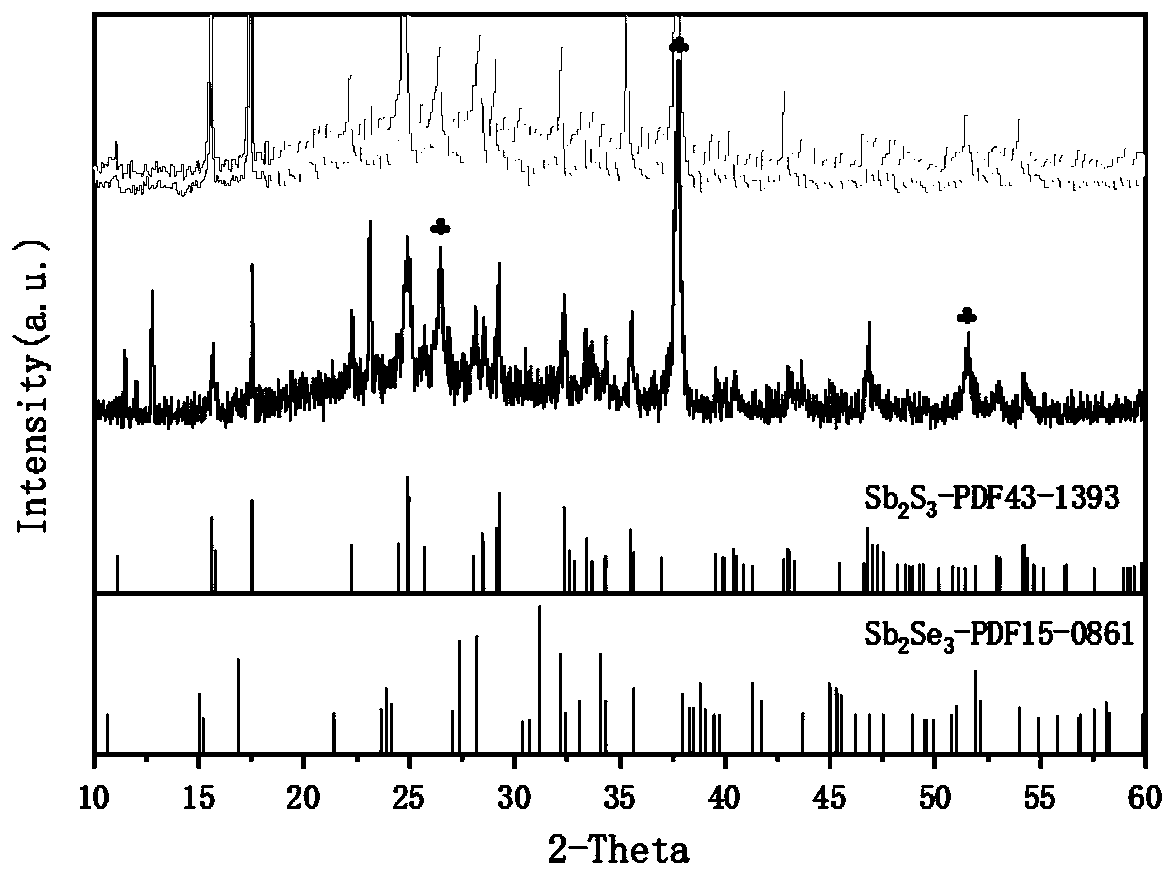

[0032] The invention provides a method for preparing a solar cell absorbing layer, comprising the following steps:

[0033] A) mixing antimony potassium tartrate, sodium thiosulfate and sodium selenosulfate with water to obtain a deposition solution;

[0034] B) the deposition solution is subjected to a hydrothermal reaction on the surface of the substrate to obtain an antimony sulfoselenide film compounded on the surface of the substrate;

[0035] C) performing annealing treatment on the obtained antimony sulfur selenide thin film in an inert gas environment to obtain a solar cell absorbing layer.

[0036] The present invention firstly prepares a deposition solution, specifically, dissolving antimony potassium tartrate and sodium thiosulfate in water to obtain a mixed solution;

[0037] An aqueous solution of sodium selenosulfate is added to the mixed solution to obtain a deposition solution required for depositing an antimony sulfur selenide film.

[0038] The aqueous solu...

Embodiment 1

[0064] 1) Clean the FTO conductive glass substrate: clean the substrate with ultrapure water, ethanol, isopropanol, and acetone in sequence for 15 minutes ultrasonically, and then clean it with oxygen plasma for 15 minutes. Deposit a CdS thin film on a clean substrate.

[0065] 2) Place the substrate obliquely in the hydrothermal reactor. Preparation of deposition solution: take a 50mL beaker, first add 40mL deionized water, then add 0.2671g antimony potassium tartrate, stir until dissolved with a stirring bar. Then add 0.7936 g of sodium thiosulfate, stir for 60 s, then add 100 μL of 0.1 M sodium selenosulfate solution, and continue stirring for 120 s to obtain a deposition solution. At this time, the concentration of antimony potassium tartrate in the deposition solution is 0.02M, the concentration of sodium thiosulfate is 0.08M, and the concentration of sodium selenosulfate is 0.00025M.

[0066] 3) Pour the deposition liquid obtained in step 2) into a hydrothermal reactio...

Embodiment 2

[0070] 1) Clean the FTO conductive glass substrate: clean the substrate with ultrapure water, ethanol, isopropanol, and acetone in sequence for 15 minutes ultrasonically, and then clean it with oxygen plasma for 15 minutes. Deposit a CdS thin film on a clean substrate.

[0071] 2) Place the substrate obliquely in the hydrothermal reactor. Preparation of deposition solution: take a 50mL beaker, first add 40mL deionized water, then add 0.2671g antimony potassium tartrate, stir until dissolved with a stirring bar. Then add 0.7936 g of sodium thiosulfate, stir for 60 s, then add 200 μL of 0.1 M sodium selenosulfate solution, and continue stirring for 120 s to obtain a deposition solution. At this time, the concentration of antimony potassium tartrate in the deposition solution is 0.02M, the concentration of sodium thiosulfate is 0.08M, and the concentration of sodium selenosulfate is 0.0005M.

[0072] 3) Pour the deposition liquid obtained in step 2) into a hydrothermal reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com