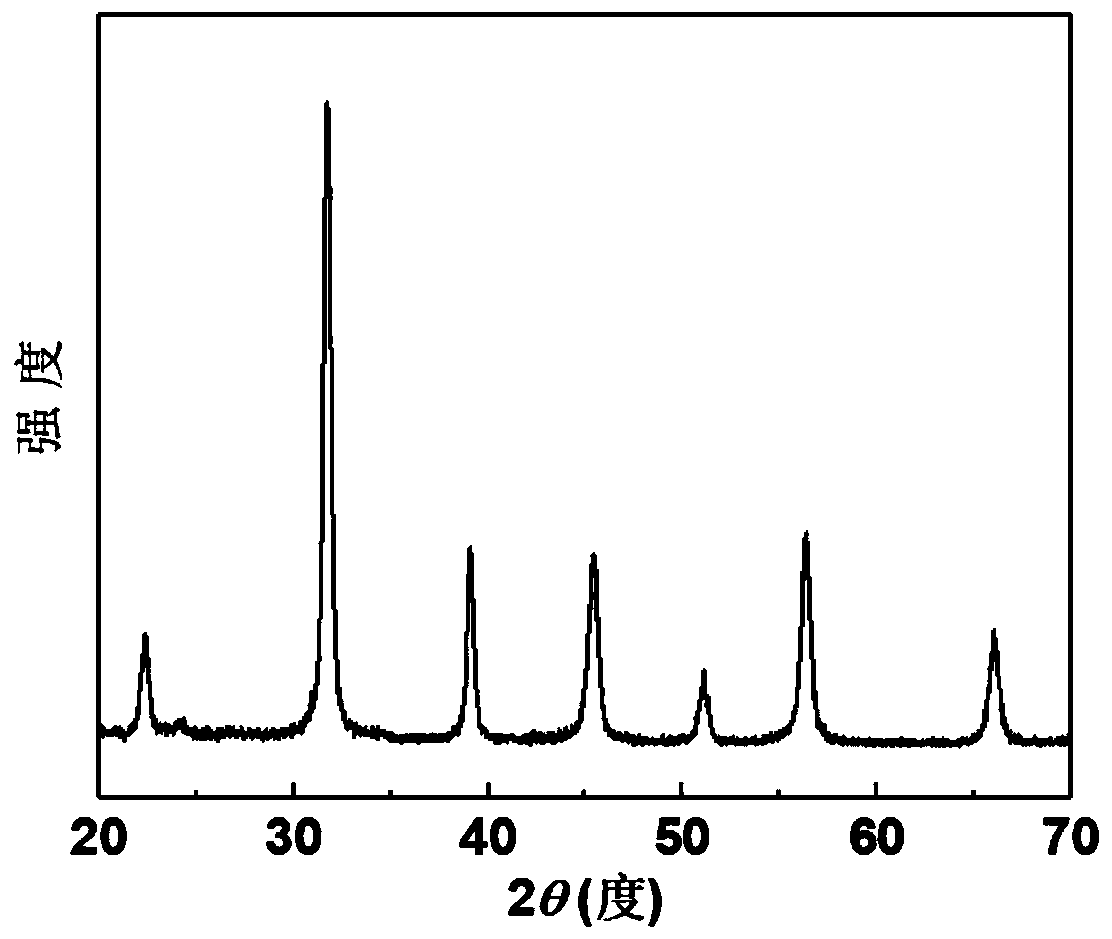

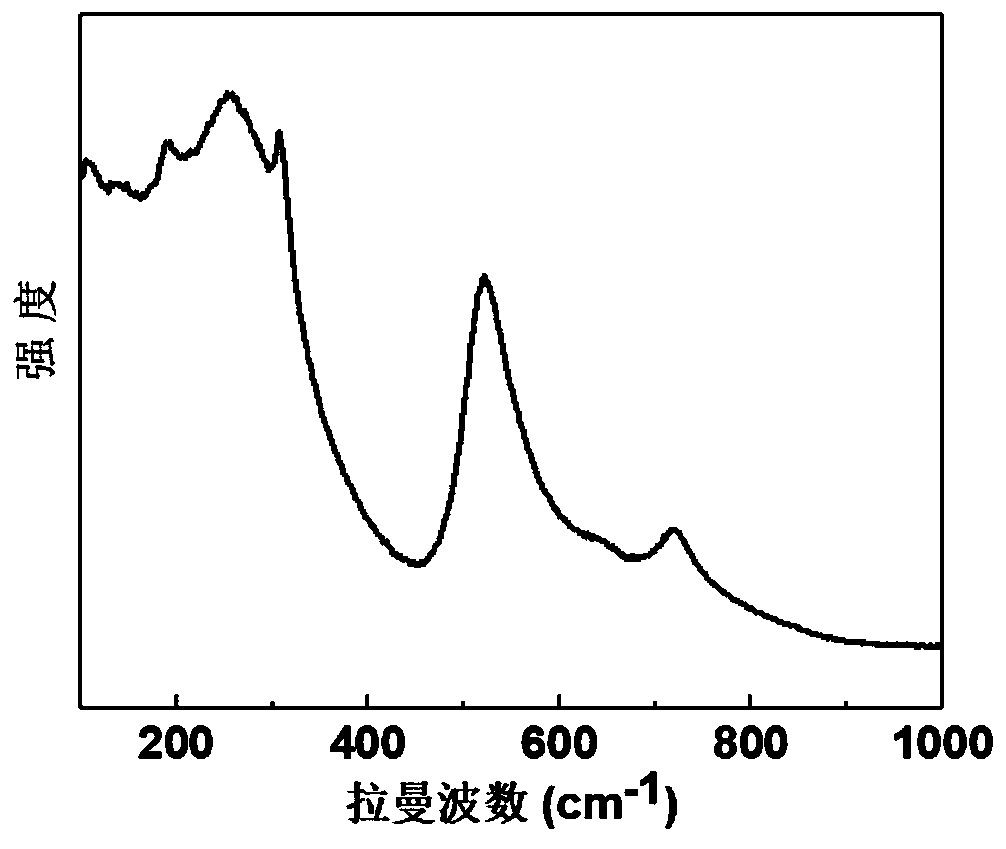

Nano barium titanate as well as preparation method and application thereof

A barium titanate and nanotechnology, applied in the field of materials, can solve problems such as unsuitable for industrial production, easy agglomeration of powder, and large amounts of waste water, and achieve good economic and environmental benefits, low operating costs, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention proposes a kind of preparation method of nanometer barium titanate, and this preparation method comprises the following steps:

[0031] mixing the titanium compound, the first surfactant and the first solvent to obtain a first solution;

[0032] mixing the barium compound, the second surfactant and the second solvent to obtain a second solution;

[0033] mixing the first solution and the second solution to obtain barium titanate colloid;

[0034] The barium titanate colloid is dried and calcined to obtain nanometer barium titanate.

[0035] Here titanium compound can be selected titanium inorganic compound, also can select titanium organic compound, and titanium compound is used as the main source of titanium for preparing nano barium titanate; Barium compound can select barium inorganic compound for use, also can select titanium organic compound, as preparation nano barium titanate main source of barium. Here, the function of the first surfacta...

Embodiment 1

[0057] Weigh 0.35mL of titanium tetrachloride, 0.2g of polyvinyl alcohol and 15mL of ethanol, and mix them to obtain the first solution; weigh 0.66g of barium chloride, 0.1g of polyvinyl alcohol and 20mL of deionized water, and mix them to obtain the second solution. Second solution; add the second solution to the first solution at a dropping rate of 1.5 drops / second, and stir while adding dropwise to obtain barium titanate colloid. Dry and calcinate the barium titanate colloid to control the drying. The temperature is 120° C., the drying time is 24 hours, the calcination temperature is 900° C., and the calcination time is 4 hours, and then nano barium titanate powder can be obtained.

Embodiment 2

[0059] Weigh 0.5mL tetraisobutyl titanate, 0.25gL-cysteine and 20mL deionized water, mix them to obtain the first solution; weigh 0.26g barium hydroxide, 0.15gL-cysteine and 20mL ethanol , and mix them to obtain the second solution; add the second solution to the first solution at a rate of 1.5 drops / second, and stir while adding, to obtain barium titanate colloid, and dry the barium titanate colloid 1. Calcination operation, controlling the drying temperature to 80°C, drying time to 12h, calcination temperature to 800°C, and calcination time to 2h, to obtain nano barium titanate powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com