A kind of waste pcb recovery treatment method and recovery treatment device

A technology of recycling and pyro-smelting, applied in separation methods, gas treatment, combined devices, etc., can solve the problems of large consumption of reagents, waste of resources, complicated processes, etc., and achieve high-efficiency separation and recovery, high recycling rate, The effect of a compact recycling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

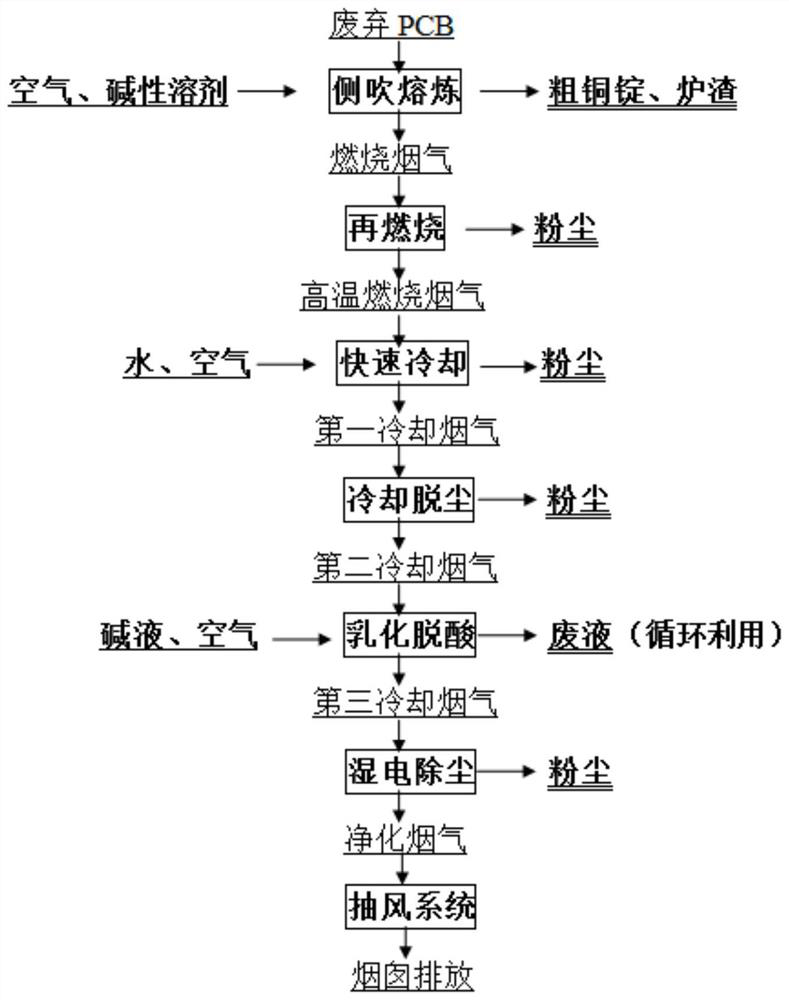

[0040] like figure 1 Shown is the embodiment of the discarded PCB recovery processing method of the present invention, comprises the following steps:

[0041] S10. The waste PCB is added to the melting furnace for pyromelting, the generated slag and metal melt enter the clarification and separation zone, and the generated combustion flue gas enters step S20 for processing, and the temperature of the melting furnace is greater than 1500°C;

[0042] S20. In step S10, the combustion flue gas is re-combusted to generate high-temperature combustion flue gas, and the combustion temperature of the re-combustion is greater than 800°C;

[0043] S30. Perform rapid cooling of the high-temperature combustion flue gas in step S20 to reduce the temperature of the high-temperature combustion flue gas to below 200° C. within 2 seconds to obtain the first cooled flue gas;

[0044] S40. Perform cooling treatment and dedusting treatment on the first cooled flue gas in step S30 to obtain second ...

Embodiment 2

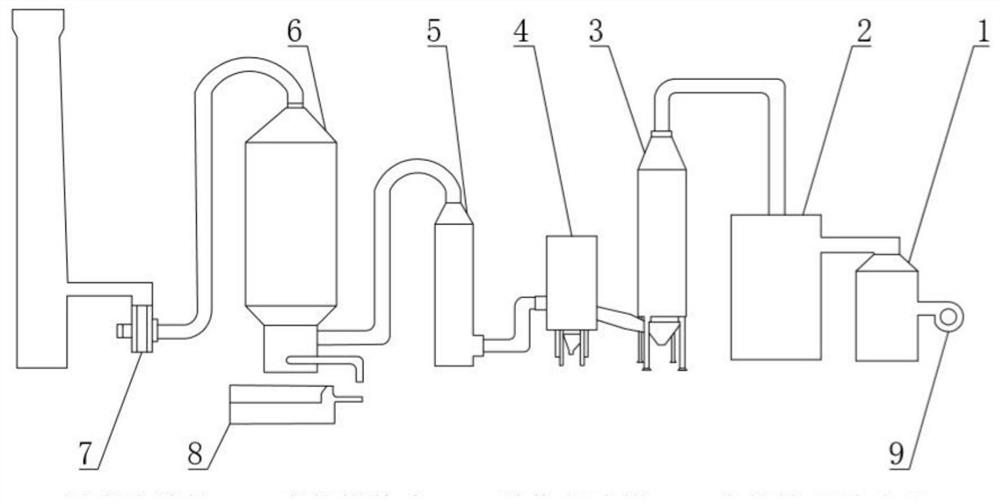

[0056] like figure 2 Shown is an embodiment of the waste PCB recovery treatment device of the present invention, including a side-blowing smelting furnace 1, a multi-stage combustion chamber 2, an atomizing quenching tower 3, a multi-tube cyclone dust collector 4, and a pneumatic emulsification and deacidification tower connected in sequence 5. Wet electrostatic precipitator 6 and ventilation system 7:

[0057] The upper part of the side-blowing smelting furnace 1 is provided with a combustion reaction zone, and the lower part of the side-blown smelting furnace 1 is provided with a clarification and separation zone for slag and molten metal. It is used to blow in oxygen-enriched air and remove the alkaline solvent of halogen elements. In this embodiment, a blower 9 can be connected to the side blowing hole to blow in oxygen-enriched air; There is a gas collecting hood; among them, the furnace wall of the side-blowing melting furnace 1 is a multi-layer structure, which is pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com