Method and system for pretreatment of waste emulsion

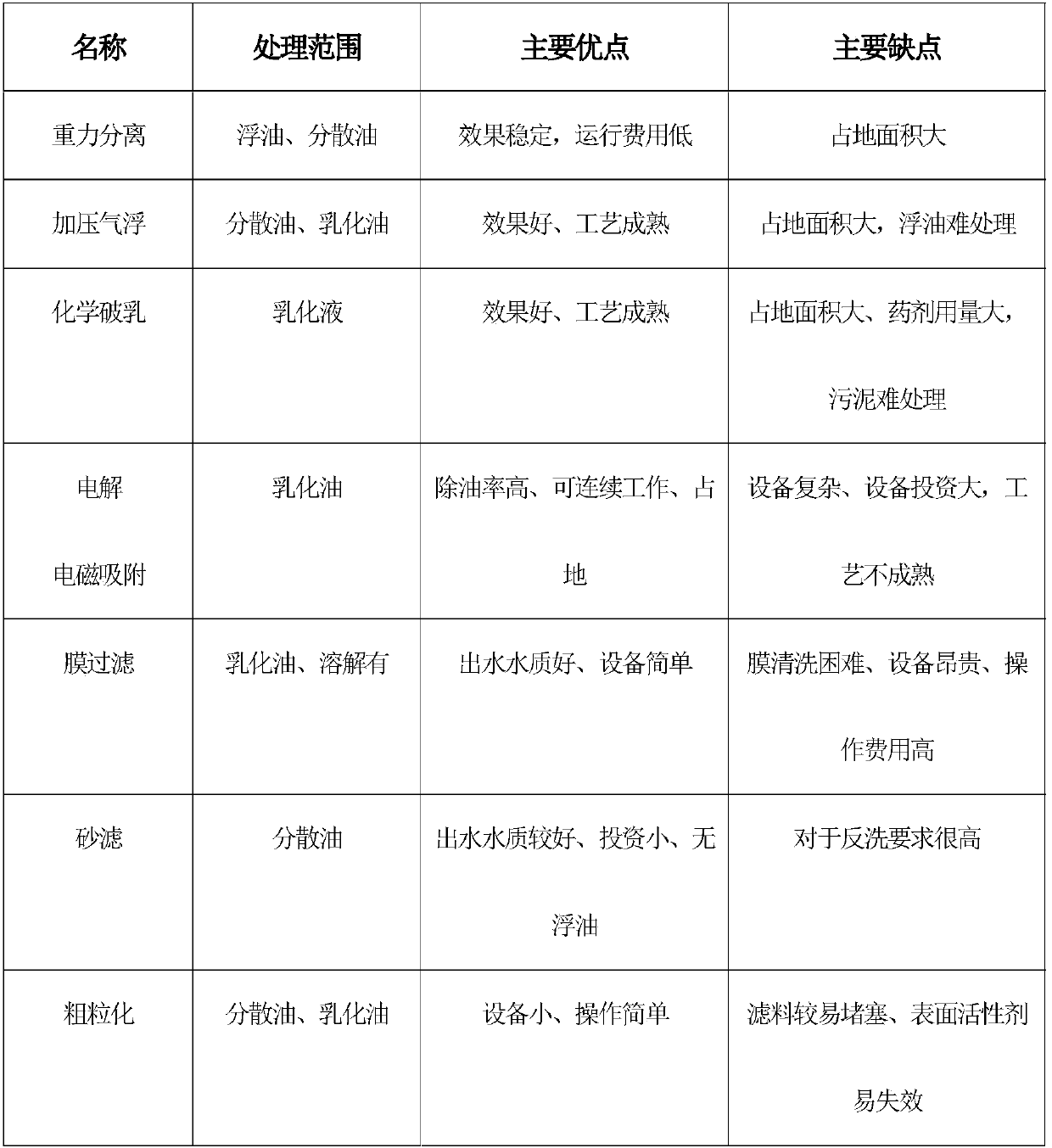

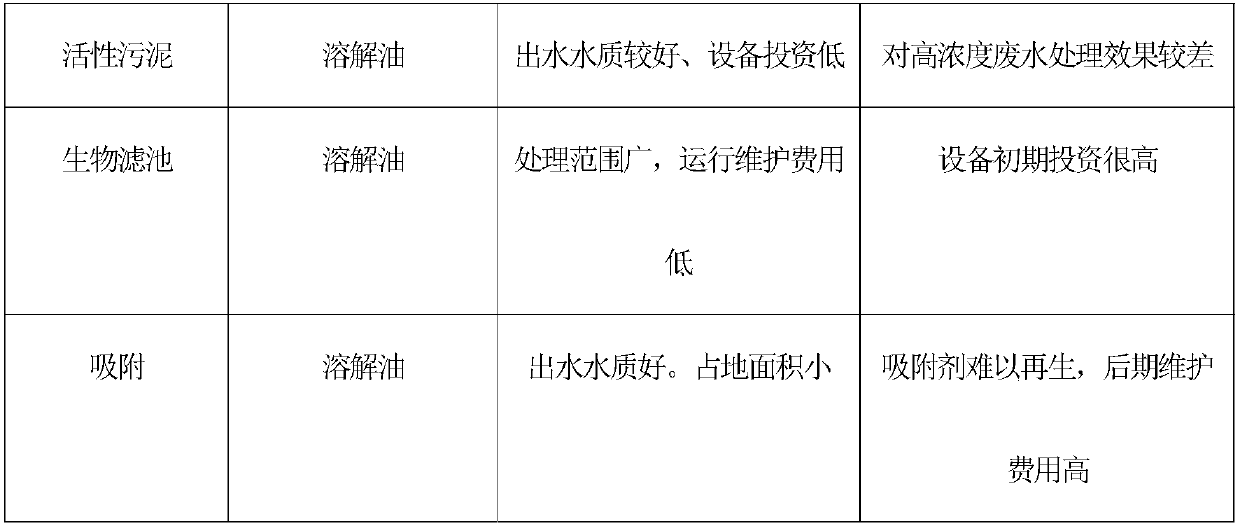

A waste emulsion and pretreatment technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problems of high COD, large discharge, and high pollution intensity of waste emulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

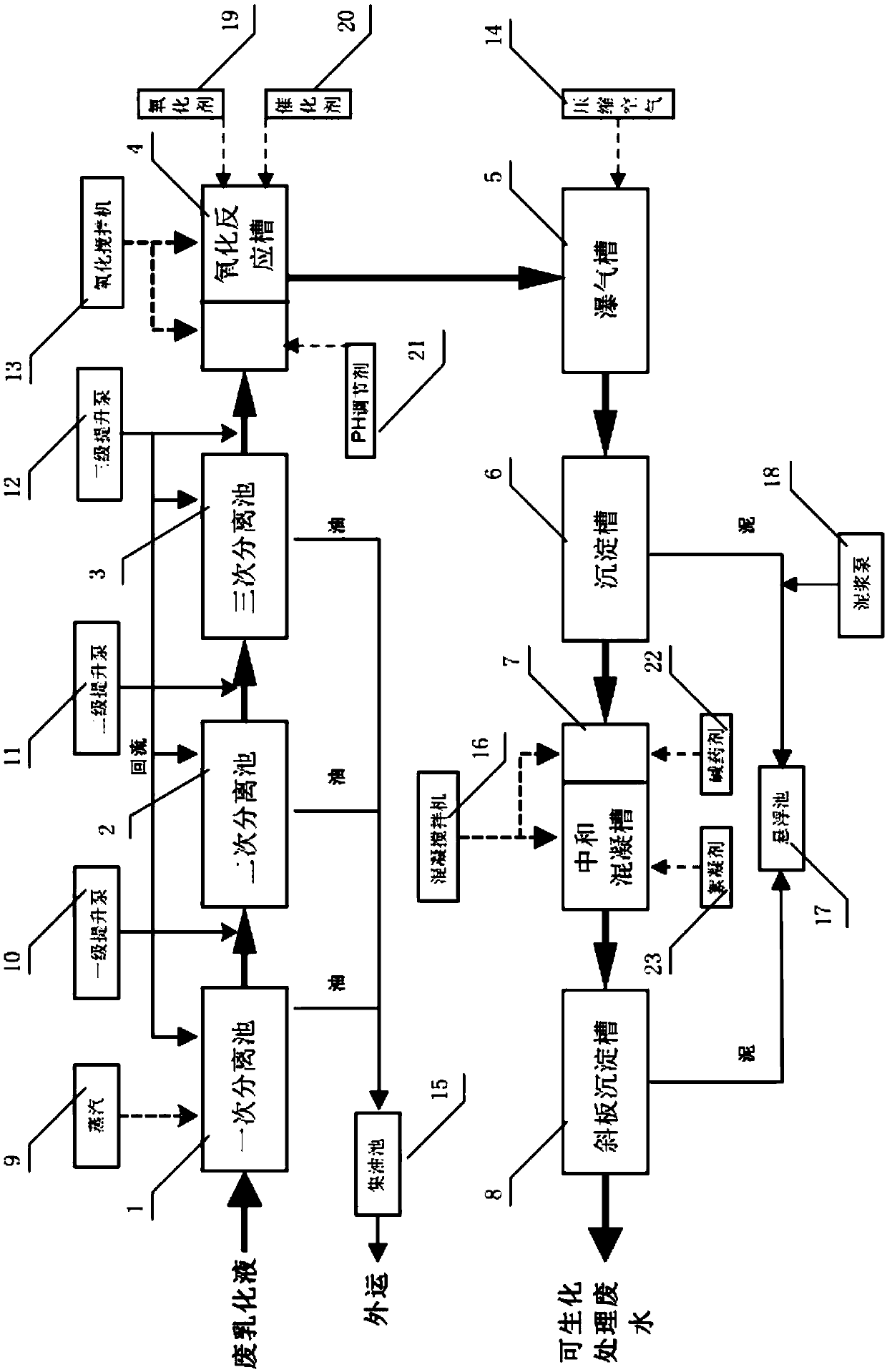

Method used

Image

Examples

Embodiment 1

[0082] The waste emulsion first enters the primary separation tank for steam heating and separation. The heating time is about 6 hours, heated to 90°C, and passed through the secondary separation. The residence time of each separation is 3 hours, and the cooling temperature is 70°C. then by 1m 3 The flow rate per hour enters the oxidation reaction tank 4, by adjusting the pH value to 2, adding oxidizing agent 20L / hour (wherein hydrogen peroxide 18L / hour, nitric acid 2L / hour), catalyst 35L / hour. and stirred through an oxidation mixer, dwelling 45 minutes. Then enter the aeration tank 5 for aeration and oxidation, and enter the sedimentation tank after a residence time of about 3 hours. Continue to stay in the sedimentation tank for 4.5 hours, and the supernatant enters the neutralization flocculation tank. By adjusting the pH value of the waste emulsion to 9, add 20 L / hour evenly. Stir with a coagulation mixer, stay for about 30 minutes, enter the inclined plate sedimentation...

Embodiment 2

[0084] The waste emulsion first enters the primary separation tank for steam heating and separation. The heating time is about 6 hours, heated to 90°C, and passed through the secondary separation. The residence time of each separation is 3 hours, and the cooling temperature is 70°C. then by 1m 3 The flow rate per hour enters the oxidation reaction tank 4, by adjusting the pH value to 3, adding oxidizing agent 30L / hour (wherein hydrogen peroxide 27L / hour, peracetic acid 3L / hour), catalyst 45L / hour. and agitated through an oxidation mixer, leaving for about 45 minutes. Then enter the aeration tank 5 for aeration and oxidation, and enter the sedimentation tank after a residence time of about 3 hours. Continue to stay in the sedimentation tank for 4.5 hours, and the supernatant enters the neutralization flocculation tank. By adjusting the pH value of the waste emulsion to 11, add 30 L / hour evenly. Stir with a coagulation mixer, stay for about 30 minutes, enter the inclined plate...

Embodiment 3

[0086] The waste emulsion first enters the primary separation tank for steam heating and separation. The heating time is about 6 hours, heated to 90°C, and passed through the secondary separation. The residence time of each separation is 3 hours, and the cooling temperature is 70°C. then at 2m 3 The flow rate per hour enters the oxidation reaction tank 4, by adjusting the pH value to 3, adding oxidant 40L / hour (wherein hydrogen peroxide 36L / hour, ammonium persulfate 4L / hour), catalyst 70L / hour. and stirred through an oxidation mixer, dwelling 30 minutes. Then enter the aeration tank 5 for aeration and oxidation, and enter the sedimentation tank after a residence time of about 2 hours. Continue to stay in the sedimentation tank for 3 hours, and the supernatant enters the neutralization flocculation tank. By adjusting the pH value of the waste emulsion to 10, add 40 L / hour evenly. Stir with a coagulation mixer, stay for about 20 minutes, enter the inclined plate sedimentation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com