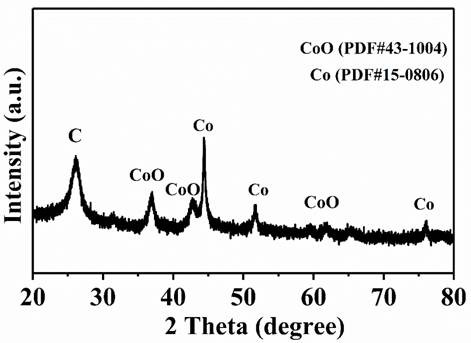

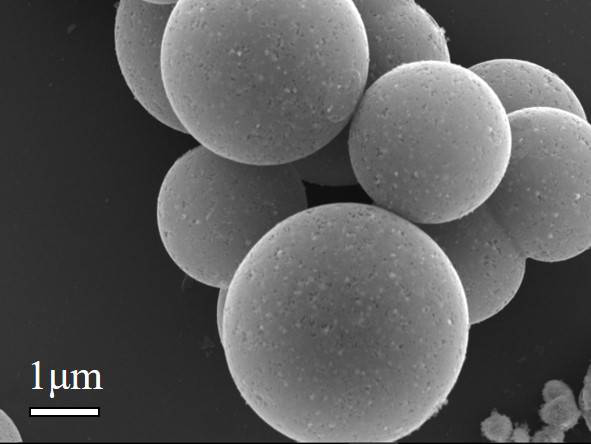

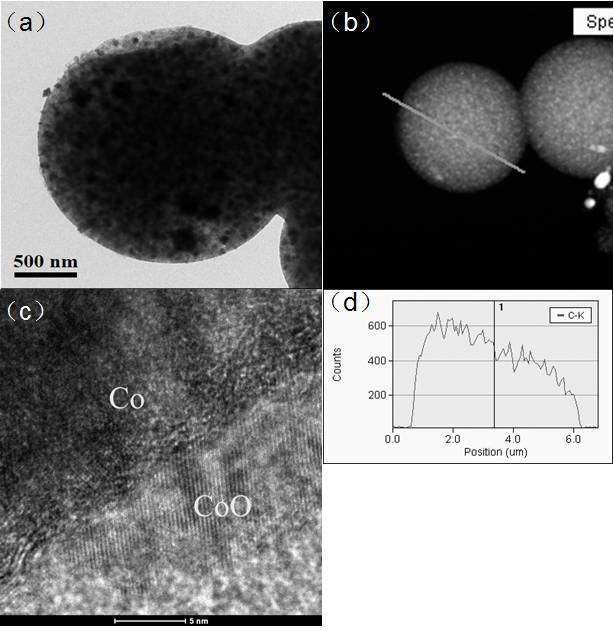

A kind of porous structure co/coo-c composite material and its preparation method and application

A composite material, porous structure technology, applied in chemical instruments and methods, other chemical processes, magnetic field/electric field shielding, etc. Absorption characteristics, strong wave absorbing ability, low density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]A preparation method of porous structure Co / CoO-C composite material includes the following steps:

[0029](1) Use an analytical balance to weigh 15 mmol glucose, 2 mmol Co (NO3)2·6H2O, 10 mmol urea;

[0030](2) Measure 60 mL deionized water into a glass beaker;

[0031](3) First slowly add glucose to the glass beaker, and then slowly add Co (NO3)2·6H2O. Urea, magnetic stirring for 1 h;

[0032](4) Transfer the uniformly mixed solution from the glass beaker to the polytetrafluoroethylene autoclave, and then react in a dry box at 190 ℃ for 15 h;

[0033](5) After the reaction is over, take out the black precipitate from the reactor, and wash it with distilled water three times, then with absolute ethanol three times, and then dry it in a drying oven at 60 ℃ for 9 hours to obtain the precursor;

[0034](6) Put the obtained precursor in a small porcelain boat in a tube furnace under a nitrogen atmosphere, and heat it up to a calcination temperature of 450 ℃ at a heating rate of 5 ℃ / min, keep it fo...

Embodiment 2

[0036]The difference from Example 1 is that the calcination temperature in step (6) is changed to 600° C., and the obtained calcination product is labeled as N-600 sample; the others are the same as in Example 1.

Embodiment 3

[0038]The difference from Example 1 is that the calcination temperature in step (6) is changed to 750° C., and the obtained calcination product is labeled as N-750 sample; the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com