Purification method of lithium difluorophosphate

A technology of lithium difluorophosphate and purification method, applied in the field of purification of lithium difluorophosphate, can solve the problems of battery damage, inability to play a lifting role, and inability to form a passivation layer on the surface of graphite electrodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

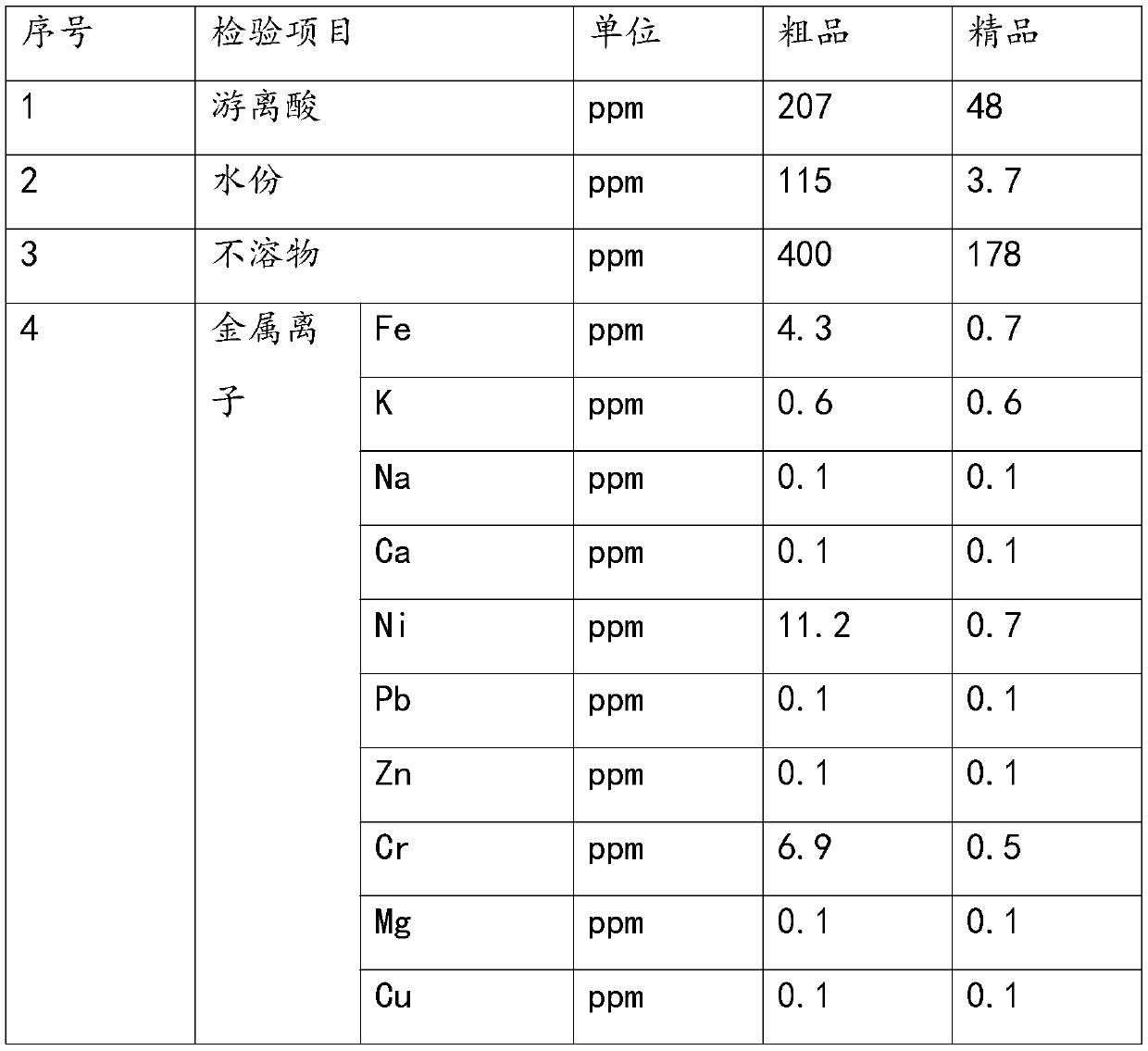

Embodiment 1

[0024] Replace the stirring tank with weighing with nitrogen until the water content is less than 15ppm, press in 100kg of ethylene glycol dimethyl ether solvent, add 25kg of lithium difluorophosphate to be purified, stir and dissolve at room temperature for 2 hours.

[0025] Start the diaphragm pump to pass the dissolved lithium difluorophosphate solution through the 4A lithiated molecular sieve tower and 5A lithiated molecular sieve tower at 30-50L / min, and return to the stirring tank after passing through the 0.1um precision filter, and circulate and dehydrate for 2 hours.

[0026] Add 65mL of hexamethyldisilazane dropwise to the stirred tank, raise the temperature to 40°C, stir for 0.5h, continue to heat up to 65°C, turn on the vacuum pump to maintain a vacuum of -0.8bar, concentrate in vacuo until the displayed weight of the stirred tank is 40kg, stop heating, Naturally lower the temperature to 40°C, turn on the circulating refrigerant and continue to cool down to 10°C, an...

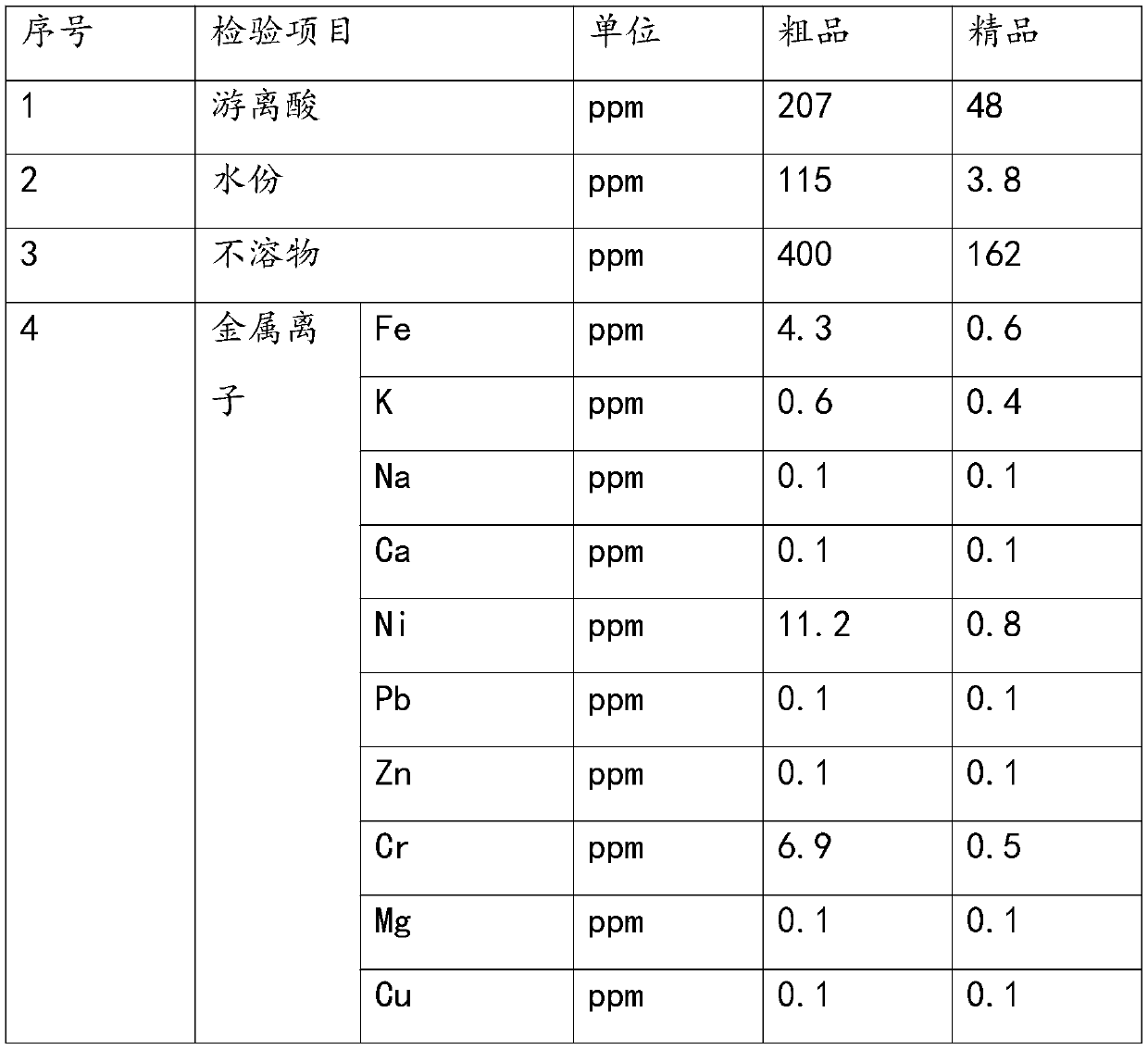

Embodiment 2

[0032] Replace the stirred tank with weighing with nitrogen until the water content is less than 15ppm, press into 120kg of acetonitrile solvent, add 25kg of lithium difluorophosphate to be purified, stir and dissolve at room temperature for 2.5h.

[0033] Start the diaphragm pump to pass the dissolved lithium difluorophosphate solution through the 4A lithiated molecular sieve tower and 5A lithiated molecular sieve tower at 30-50L / min, and return to the stirring tank after passing through the 0.1um precision filter for 3 hours of circular dehydration. Add 65mL of dicyclohexylcarbodiimide dropwise to the stirred tank, raise the temperature to 40°C, stir for 0.5h, continue to raise the temperature to 65°C, turn on the vacuum pump to maintain a vacuum degree of -0.8bar, concentrate in vacuo until the displayed weight of the stirred tank is 40kg, stop heating, Naturally lower the temperature to 40°C, turn on the circulating refrigerant and continue to cool down to 0°C, and keep war...

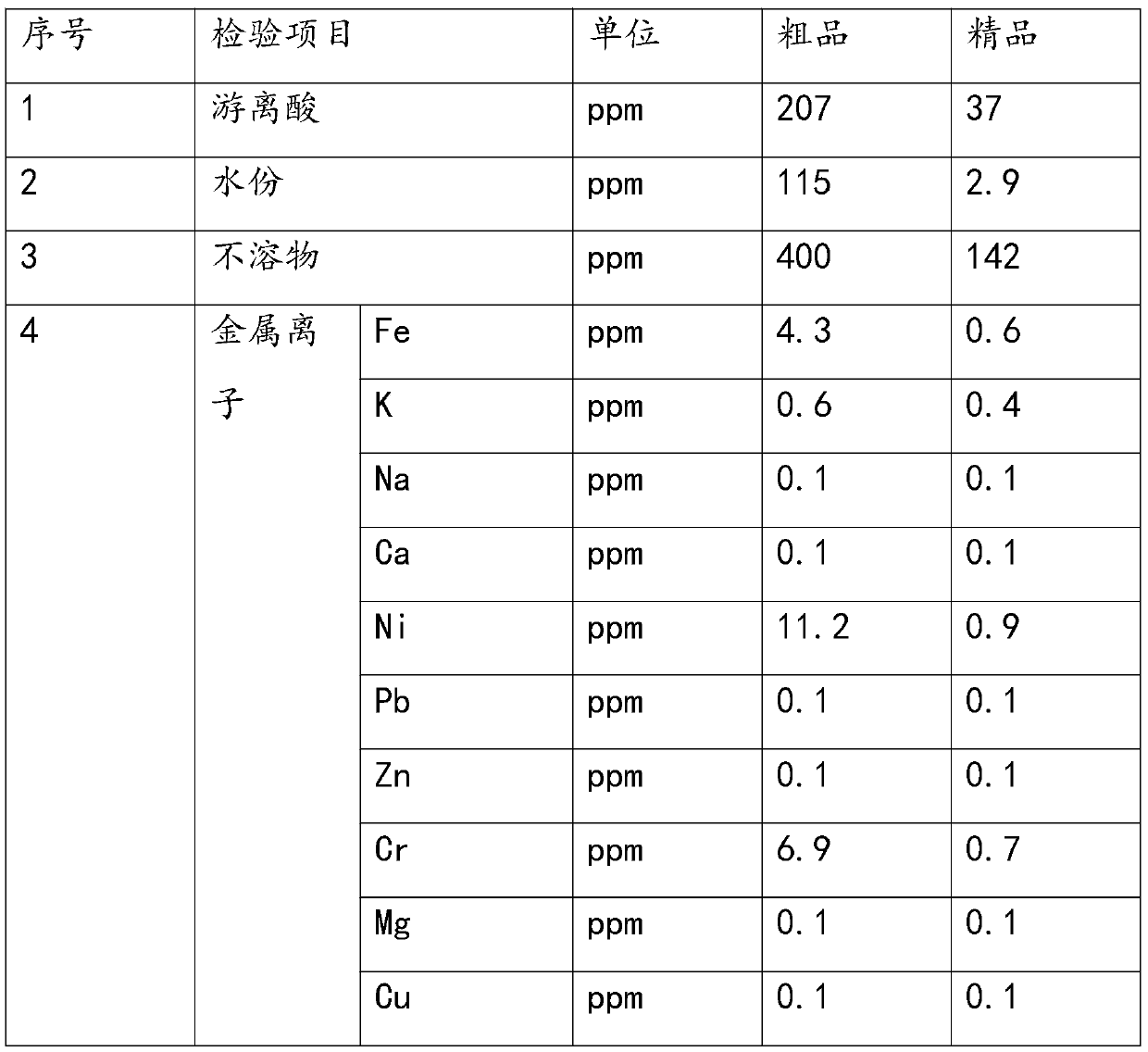

Embodiment 3

[0039] Replace the stirring tank with weighing with nitrogen until the water content is less than 15ppm, press into 100kg of ethylene glycol methyl ether solvent, add 25kg of lithium difluorophosphate to be purified, stir and dissolve at room temperature for 2.5h.

[0040] Start the diaphragm pump to pass the dissolved lithium difluorophosphate solution through the 4A lithiated molecular sieve tower and 5A lithiated molecular sieve tower at 30-50L / min, and return to the stirring tank after passing through the 0.1um precision filter, and circulate and dehydrate for 2 hours.

[0041] Add 50mL of nonamethyltrisilazane dropwise to the stirred tank, raise the temperature to 50°C, stir for 0.5h, continue to raise the temperature to 65°C, turn on the vacuum pump to maintain a vacuum of -0.8bar, concentrate in vacuo until the displayed weight of the stirred tank is 40kg, stop heating, Naturally lower the temperature to 40°C, turn on the circulating refrigerant and continue to cool down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com