Nonionic fluorocarbon surfactant suitable for fire extinguishing agent and preparation method thereof

A technology of fluorocarbon surface and active agent, which is applied in the direction of fire prevention equipment, etc., can solve the problems of reburning and not being able to suppress the volatilization of hot oil well, so as to prevent volatilization, control natural and combustion accidents of automobiles, and reduce personnel and property losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add tetrahydrofuran 100mL, dodecyl polyoxyethylene ether-25 135.0g (0.105mol) and triethylamine 10.6g (0.105 mol), turn on the stirrer to mix it evenly; slowly add 40.0 g (0.10 mol) of tetrafluoroethylene tetramer dropwise from the dropping funnel, and control the rate of addition to keep the temperature in the reaction bottle below 60°C; After the ethylene tetramer is added dropwise, heat to a slight boil (about 66°C), continue stirring for 6 hours, add about 20 g of anhydrous sodium sulfate, stop stirring, let stand overnight, and filter the solution into a 1L three-necked flask.

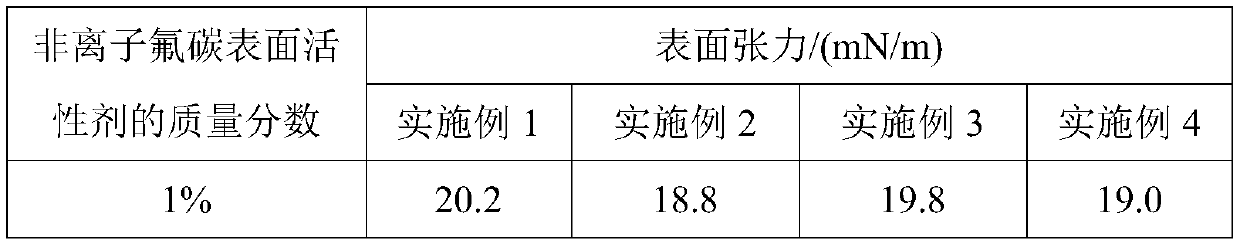

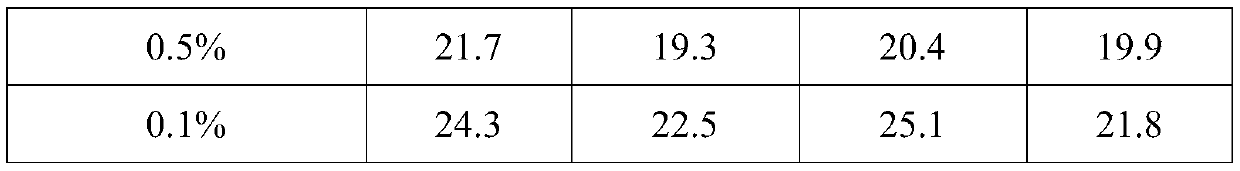

[0022] A 1L three-necked flask was equipped with a distillation head, a condenser tube, and a thermometer for distillation, and the THF was distilled off. Add 450g of ethylene glycol butyl ether solution with a mass fraction of 25%, to obtain a fluorocarbon surfactant with a mass fraction of 27-30%. After performance testing, when the mass percentage is 1.0%, its surface tension is 20.2mN / ...

Embodiment 2

[0025] Add tetrahydrofuran 100mL, dodecyl polyoxyethylene ether-35 189.9g (0.110mol) and triethylamine 10.6g (0.105 mol), turn on the stirrer to mix evenly; slowly add 66.4g (0.10mol) of hexafluoropropylene oxide tetramer dropwise from the dropping funnel, and control the rate of addition to keep the temperature in the reaction bottle below 60°C; After the hexafluoropropylene oxide tetramer is added dropwise, heat to a slight boil (about 66°C), continue to stir for 8 hours, add about 25g of anhydrous sodium sulfate, stop stirring, leave it overnight, and filter the solution into a 1L three-necked flask .

[0026] A 1L three-necked flask was equipped with a distillation head, a condenser tube, and a thermometer for distillation, and the THF was distilled off. Add 510 g of ethylene glycol butyl ether solution with a mass fraction of 10%, to obtain a fluorocarbon surfactant with a mass fraction of 27-30%. After performance testing, when the mass percentage is 1.0%, its surface ...

Embodiment 3

[0029] Add isopropyl ether 100mL, lauryl alcohol polyoxyethylene ether-25 154.3g (0.12mol) and triethylamine 10.6g in a 500mL three-necked flask equipped with a reflux condenser tube with a drying tube, a thermometer and a dropping funnel (0.105mol), turn on the stirrer to mix it evenly; slowly add 45.0g (0.10mol) of hexafluoropropylene trimer dropwise from the dropping funnel, and control the rate of addition to keep the temperature in the reaction bottle below 60°C; After the hexafluoropropylene trimer is added dropwise, heat to a slight boil (about 69°C), continue stirring for 10 h, add about 20 g of anhydrous sodium sulfate, stop stirring, let stand overnight, and filter the solution into a 1L three-necked flask.

[0030] A 1L three-necked flask was equipped with a distillation head, a condenser tube, and a thermometer for distillation, and the THF was distilled off. Add 450g of ethylene glycol butyl ether solution with a mass fraction of 40%, to obtain a fluorocarbon surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com