Preparation method of conjugated carboxylate negative electrode material of lithium ion battery

A conjugated carboxylate and lithium-ion battery technology, applied in the field of electrochemistry, can solve problems such as poor conductivity, low capacity, and poor cycle stability, and achieve the effects of increasing specific energy density, increasing specific capacity, and improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

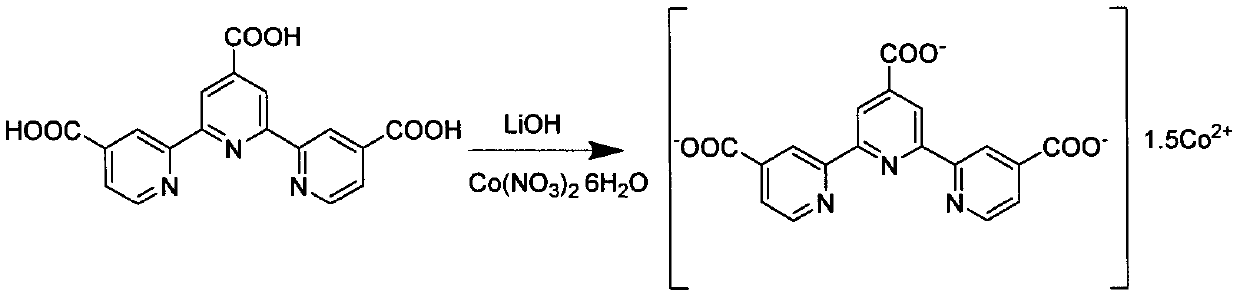

[0021] The preparation method of a conjugated carboxylate negative electrode material for a lithium ion battery described in this embodiment specifically includes the following steps.

[0022] (1) Add 0.767g of [2,2':6',2"-terpyridine]-4,4',4"-tricarboxylic acid into 50mL of water and stir at room temperature for 1 hour to obtain a white emulsion. Another 0.2626g LiOH·H 2 O was completely dissolved in 50mL of water, slowly added to the above solution, continued to stir at 60°C for 4h, evaporated the solvent water, and dried to obtain a light yellow solid, namely [2,2':6',2"-terpyridine]-4, 4',4"-Lithium tricarboxylate.

[0023] (2) Dissolve 0.8045g of the material obtained in step (1) and 0.9167g of cobalt nitrate hexahydrate in 80mL of water, react at 60°C for 5h, filter and dry to obtain a light red solid, namely [2,2':6' ,2″-terpyridine]-4,4′,4″-cobalt tricarboxylate.

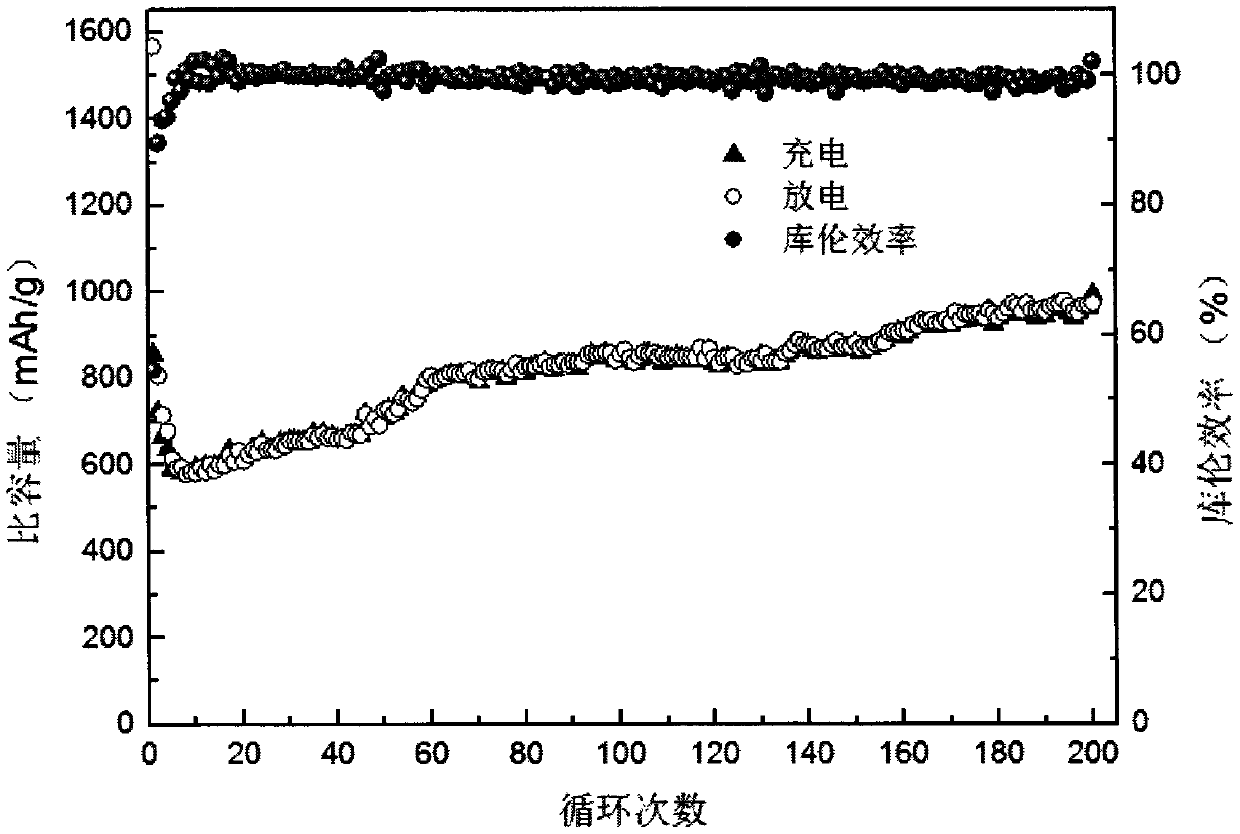

[0024] Preparation of electrodes: Mix and grind the conjugated carboxylate negative electrode material...

Embodiment 2

[0027] The preparation method of a conjugated carboxylate negative electrode material for a lithium ion battery described in this embodiment specifically includes the following steps.

[0028] (1) Add 0.767g of [2,2':6',2"-terpyridine]-4,4',4"-tricarboxylic acid into 50mL of water and stir at room temperature for 1 hour to obtain a white emulsion. Another 0.2626g LiOH·H 2 O was completely dissolved in 50mL of water, slowly added to the above solution, continued to stir at 60°C for 4h, evaporated the solvent water, and dried to obtain a light yellow solid, namely [2,2':6',2"-terpyridine]-4, 4',4"-Lithium tricarboxylate.

[0029] (2) Take 0.8045g of the material prepared in step (1) and 0.9159g of nickel nitrate hexahydrate and completely dissolve it in 80mL of water, react at 60°C for 5h, filter and dry to obtain a light green solid, namely [2,2':6' , 2″-terpyridine]-4,4′, 4″-nickel tricarboxylate, the electrode preparation method and electrochemical performance test are the ...

Embodiment 3

[0031] The preparation method of a conjugated carboxylate negative electrode material for a lithium ion battery described in this embodiment specifically includes the following steps.

[0032] (1) Add 0.767g of [2,2':6',2"-terpyridine]-4,4',4"-tricarboxylic acid into 50mL of water and stir at room temperature for 1 hour to obtain a white emulsion. Another 0.2626g LiOH·H 2 O was completely dissolved in 50mL of water, slowly added to the above solution, continued to stir at 60°C for 4h, evaporated the solvent water, and dried to obtain a light yellow solid, namely [2,2':6',2"-terpyridine]-4, 4',4"-Lithium tricarboxylate.

[0033] (2) Take 0.8045g of the material prepared in step (1) and 0.7610g of copper nitrate hexahydrate and completely dissolve it in 80mL of water, react at 60°C for 5h, filter and dry to obtain a light blue solid, namely [2,2′:6 ', 2"-terpyridine]-4,4', 4"-copper tricarboxylate, the electrode preparation method and electrochemical performance test are the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com