Preparation method of metal and alloy nanocrystalline

An alloy nanocrystal and metal technology, applied in the field of metal and alloy nanocrystal preparation, can solve problems such as restricting the large-scale production and practical application of nano-alloys, difficulty in separation and purification of nanomaterials, poor homogeneity in the same batch, etc. In industrial production, good catalytic performance and stability, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

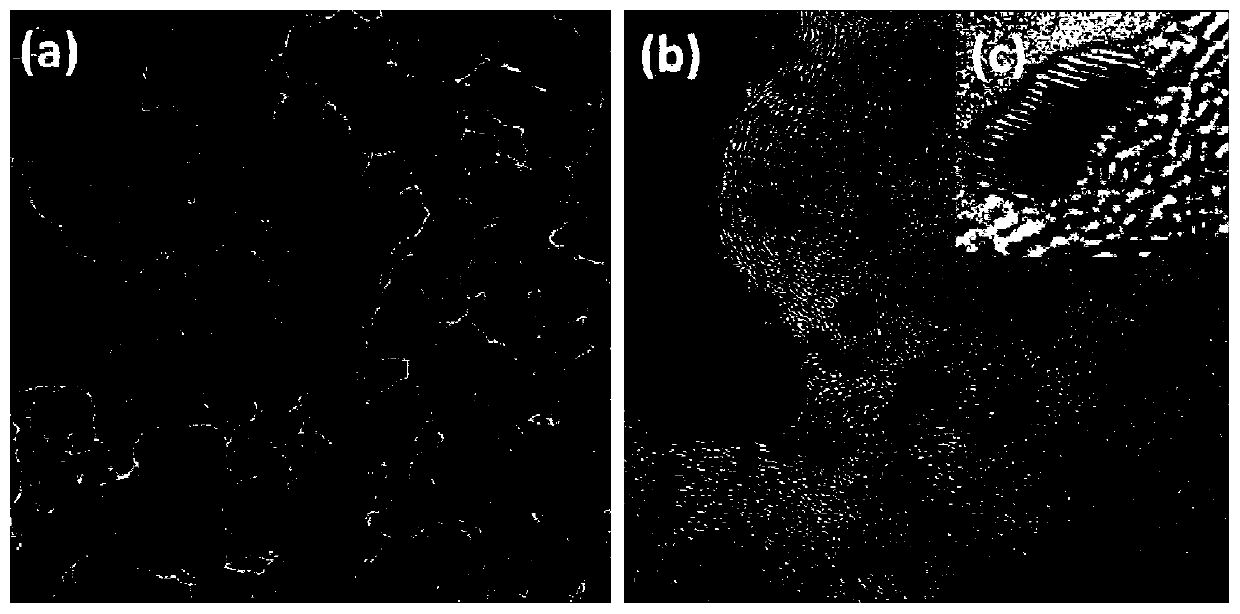

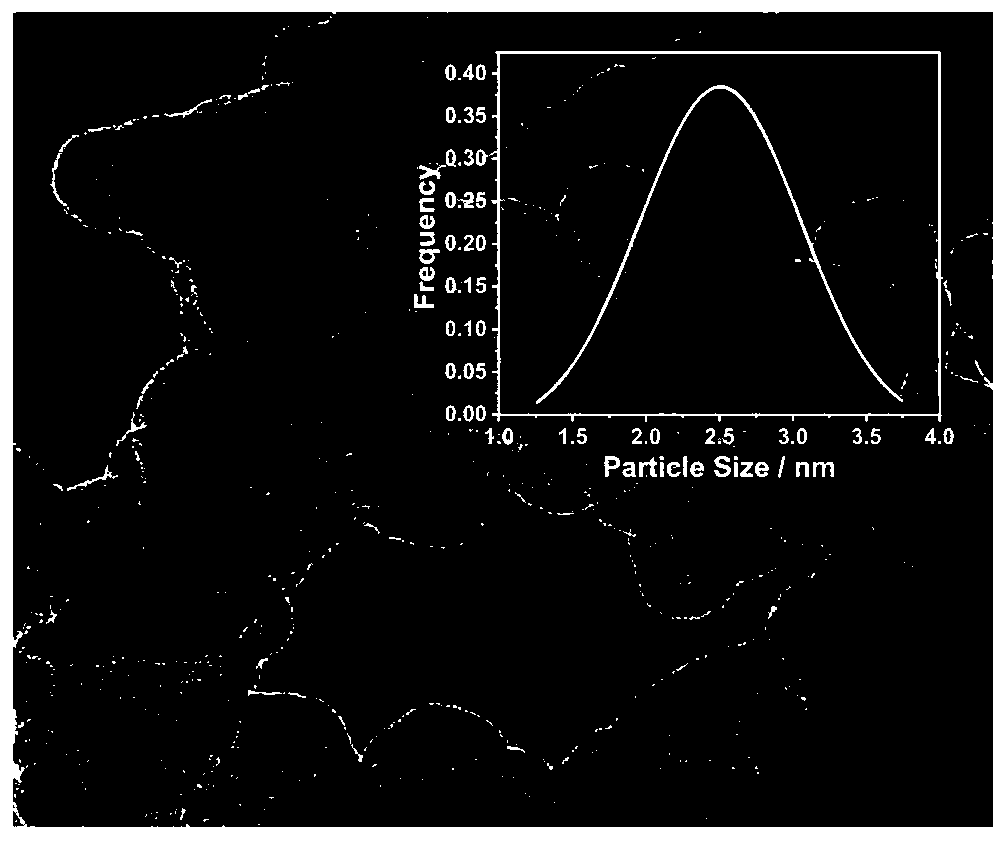

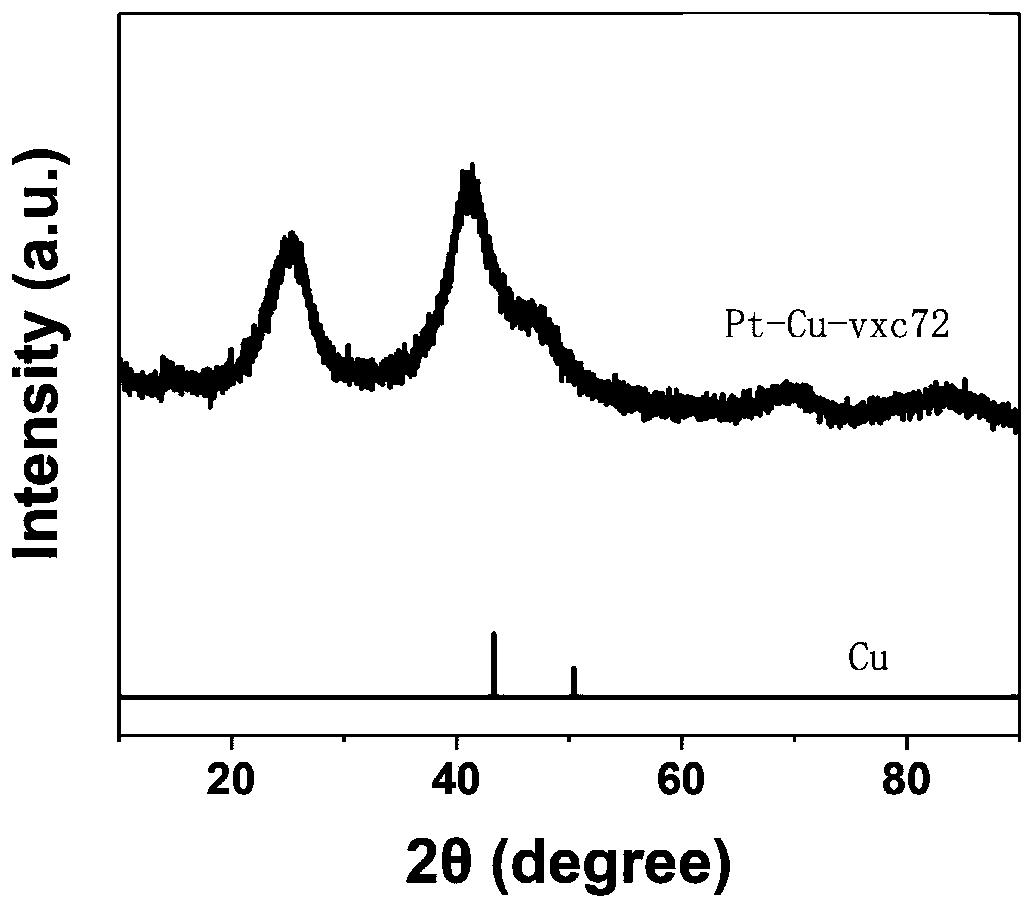

[0029] Preparation steps of Pt-Cu-vxc72:

[0030] (1) Take 13 mg of copper acetylacetonate powder and 20 mg of chloroplatinic acid as raw materials, and 51.6 mg of conductive carbon black of the model vxc72 as a carrier, add it to 80 ml of ethylene glycol dimethyl ether, stir well and ultrasonically for 5 minutes obtain its dispersion;

[0031] (2) 0.1 gram of metal sodium and 0.3 gram of metal potassium are cut into small pieces and added into ethylene glycol dimethyl ether and pressed into potassium-sodium alloy droplets respectively, and 160 microliters of potassium-sodium alloy droplets are added to the step ( 1) In the obtained dispersion liquid, the dispersion liquid is then subjected to high-speed shearing with a high-speed shear emulsifier at 25° C. and under the protection of argon, with a shear rate of 10,000 rpm and a shear time of 1 minute;

[0032] (3) The crude product of step (2) was washed 3 times with absolute ethanol, and then the washed product was washed 5...

Embodiment 2

[0040] Preparation steps of Pt-Cu-Fe-vxc72:

[0041] (1) With 35.4 milligrams of iron acetylacetonate powder, 26 milligrams of copper acetylacetonate and 40 milligrams of chloroplatinic acid as raw materials, with 125.6 milligrams of models as the conductive carbon black of vxc72 as a carrier, join in 80 milliliters of ethylene glycol dimethyl ether, Stir evenly and ultrasonically for 5 minutes to obtain its dispersion;

[0042] (2) Cut 0.1 gram of metal sodium and 0.3 gram of metal potassium into small pieces and add them to ethylene glycol dimethyl ether and press them into droplets. Take 160 microliters of alloy droplets and add them to the dispersed mixture obtained in step (1). liquid, and then carry out high-speed shearing on the dispersion liquid with a high-speed shear emulsifier at 25°C and under the protection of argon, the shear rate is 10000rpm, and the shear time is 1 minute;

[0043] (3) Wash the crude product of step (2) 3 times with absolute ethanol, then wash...

Embodiment 3

[0045] Preparation steps of Pt-Fe-vxc72:

[0046] (1) With 17.7 mg of iron acetylacetonate powder and 20 mg of chloroplatinic acid as raw materials, 51.2 mg of conductive carbon black with a type of vxc72 as a carrier, added to 80 ml of ethylene glycol dimethyl ether, stirred evenly and ultrasonicated for 5 minutes obtain its dispersion;

[0047] (2) Cut 0.1 gram of metal sodium and 0.1 gram of metal potassium into small pieces and add them to ethylene glycol dimethyl ether and press them into droplets. Take 160 microliters of alloy droplets and add them to the dispersed mixture obtained in step (1). liquid, and then carry out high-speed shearing on the dispersion liquid with a high-speed shear emulsifier at 25°C and under the protection of argon, the shear rate is 10000rpm, and the shear time is 1 minute;

[0048] (3) The crude product of step (2) was washed 3 times with absolute ethanol, and then the washed product was washed 5 times with deionized water, and the obtained p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com