Environment-friendly thermal-insulation decorative foamed ceramic plate and preparation method thereof

A foamed ceramic plate, an environmentally friendly technology, applied in ceramic products, ceramic material production, clay products, etc., can solve the problem of lack of good utilization methods, and achieve high bending strength, low production energy consumption, and firing temperature. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

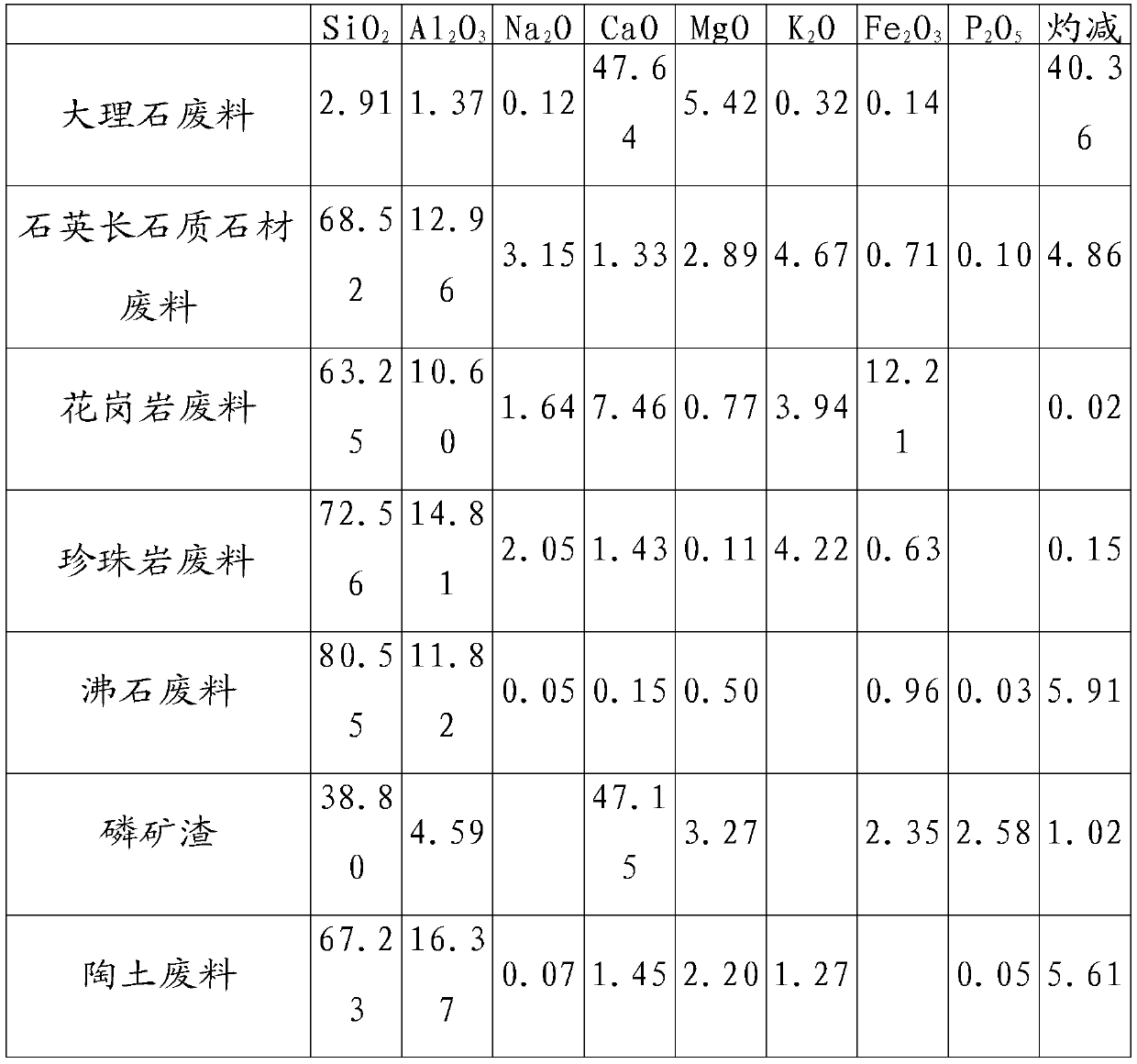

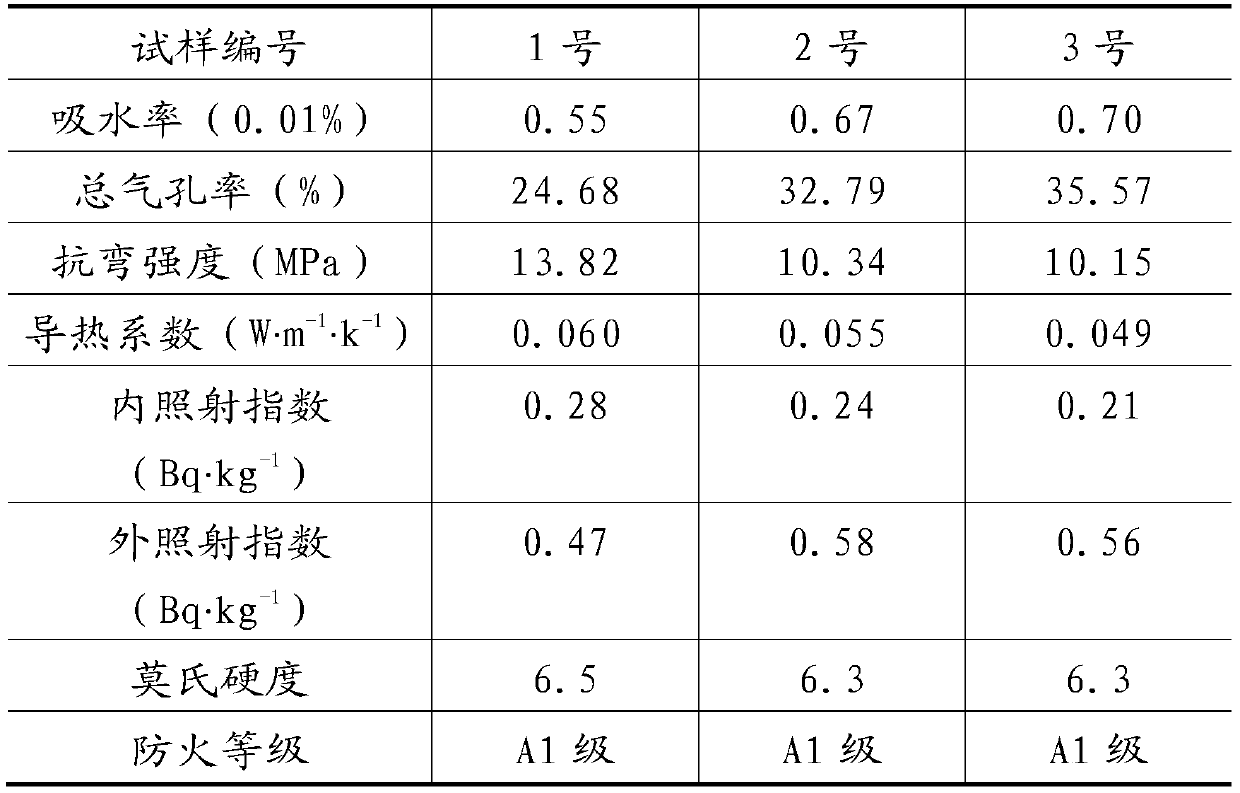

Embodiment 1

[0022] The raw materials are reinforced with 65% of marble waste, 10% of perlite waste, 15% of zeolite waste, 2% of phosphate slag, 5% of clay waste, 0.5% of starch, 1% of iron oxide, 1% of sodium tripolyphosphate, and ceramic body. After 12 hours of dry ball milling in a ball mill, pass through a 225-mesh sieve and dry press at 35 MPa to obtain a 30mm thick adobe, and reduce the moisture content of the adobe to 7% in the drying room, and then Send it into the roller kiln, burn it at the highest temperature of 950°C for 100 minutes, and then cool it naturally.

Embodiment 2

[0024] The raw materials are 61.4% of quartz feldspar stone waste, 15% of perlite waste, 10% of zeolite waste, 1% of phosphate slag, 9% of clay waste, 0.1% of polyethylene glycol (PEG4000), 3% of iron oxide, lemon Sodium acid 0.2% and ceramic body reinforcing agent 0.3% by mass are dry-milled in a ball mill for 10 hours, passed through a 250-mesh sieve, and then dry-pressed at 35MPa to obtain a 60mm-thick brick. The moisture content of the product is reduced to 5%, and then sent to the roller kiln for 80 minutes at the highest temperature of 980 ° C, and then naturally cooled.

Embodiment 3

[0026] The raw materials are 50% of granite waste, 16% of perlite waste, 18% of zeolite waste, 3% of phosphate slag, 10% of clay waste, 0.3% of urea, 1.5% of iron oxide, 0.8% of sodium lignosulfonate, ceramic body The mass ratio of 0.4% of the reinforcing agent is dry-milled in the ball mill for 11 hours, passed through a 200-mesh sieve, and then dry-pressed at 35MPa to obtain a 45mm thick brick, and the moisture content of the brick is reduced to 6% in the drying room. It is then sent to a roller kiln for 90 minutes at a maximum temperature of 1110°C and then cooled naturally.

[0027] Among the above raw materials, perlite waste comes from Qingshan Township, Luoshan County, Henan Province; zeolite waste comes from Zhubian Town, Junan County, Shandong Province; phosphorite slag comes from Yangdun Town, Songxi County, Fujian Province; clay waste comes from Luwu Town, Lingshan County, Guangdong Province , The granite waste comes from Shuitou Town, Nan'an City, Fujian Province, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com