A kind of process method of using special acrylate wastewater to prepare color fixing agent

A technology of acrylate and process method, which is applied in the fields of dyeing, textiles and papermaking, etc. It can solve the problems that the technical problems cannot be effectively overcome, the water inlet conditions are relatively high, and cannot be promoted, so as to eliminate secondary waste liquid and prepare The effect is simple and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

[0030] An embodiment of the present invention provides a process for preparing a color-fixing agent using special acrylate wastewater, comprising:

[0031] Mixing the waste liquid containing acrylate with dimethyl diallyl ammonium chloride and a chain transfer agent to obtain a mixed liquid;

[0032] After the mixed solution is heated to 75-85°C, the initiator sodium persulfate is added, and reacted for 1 hour, and free radical polymerization is carried out during the reaction;

[0033] The temperature of the mixed solution added with the sodium persulfate is lowered to 25°C to obtain a polymer color fixing agent with a molecular weight of 50-200 million and a residual rate of Shuangjian monomer of less than 0.5%;

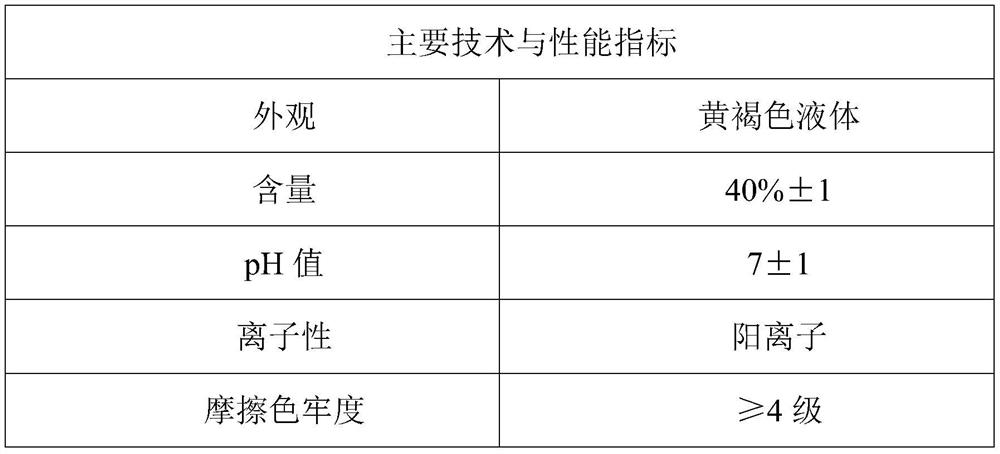

[0034] The main technical indicators of the polymer color fixing agent are as follows:

[0035]

[0036] Shuangjian monomer in the waste li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com