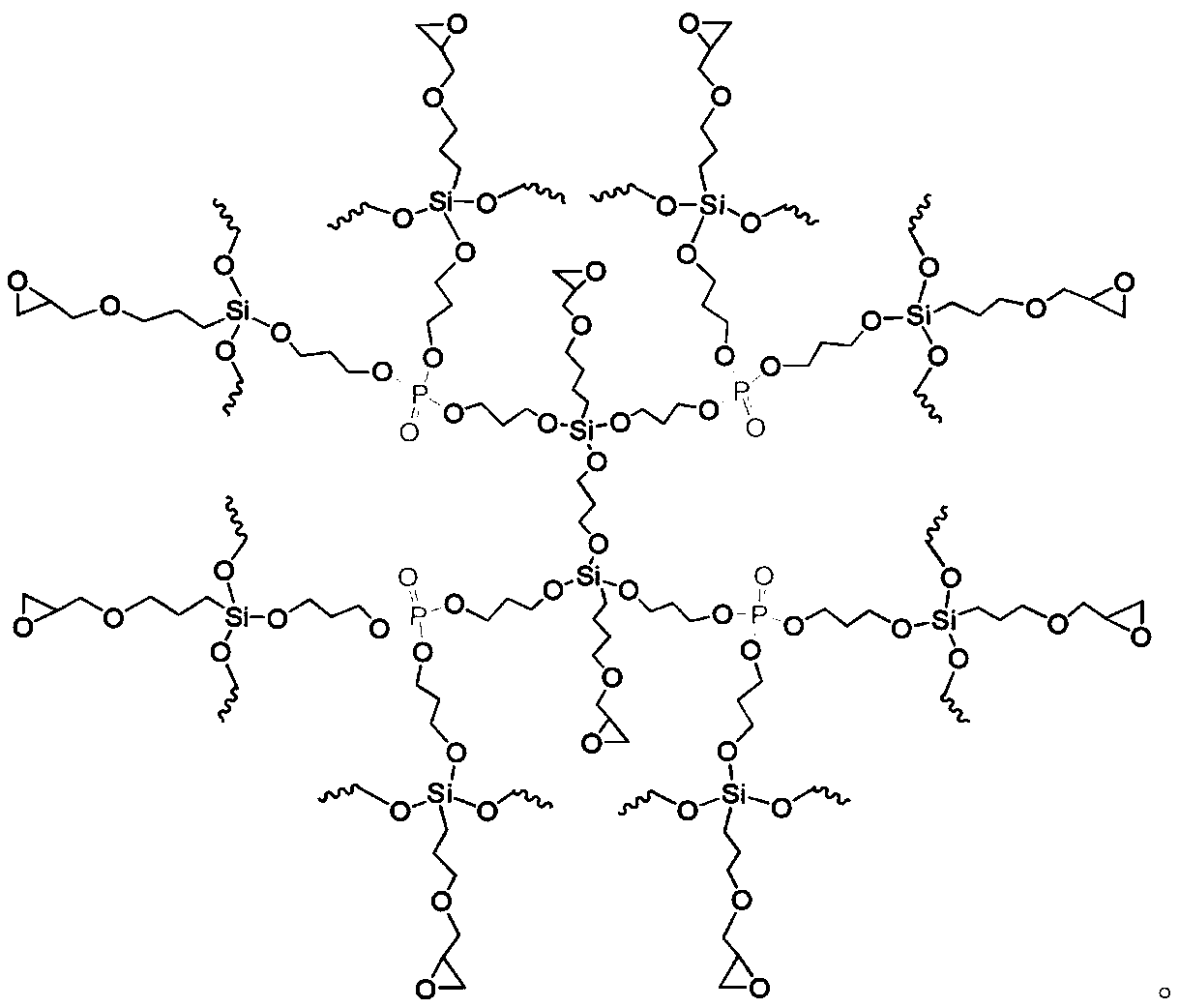

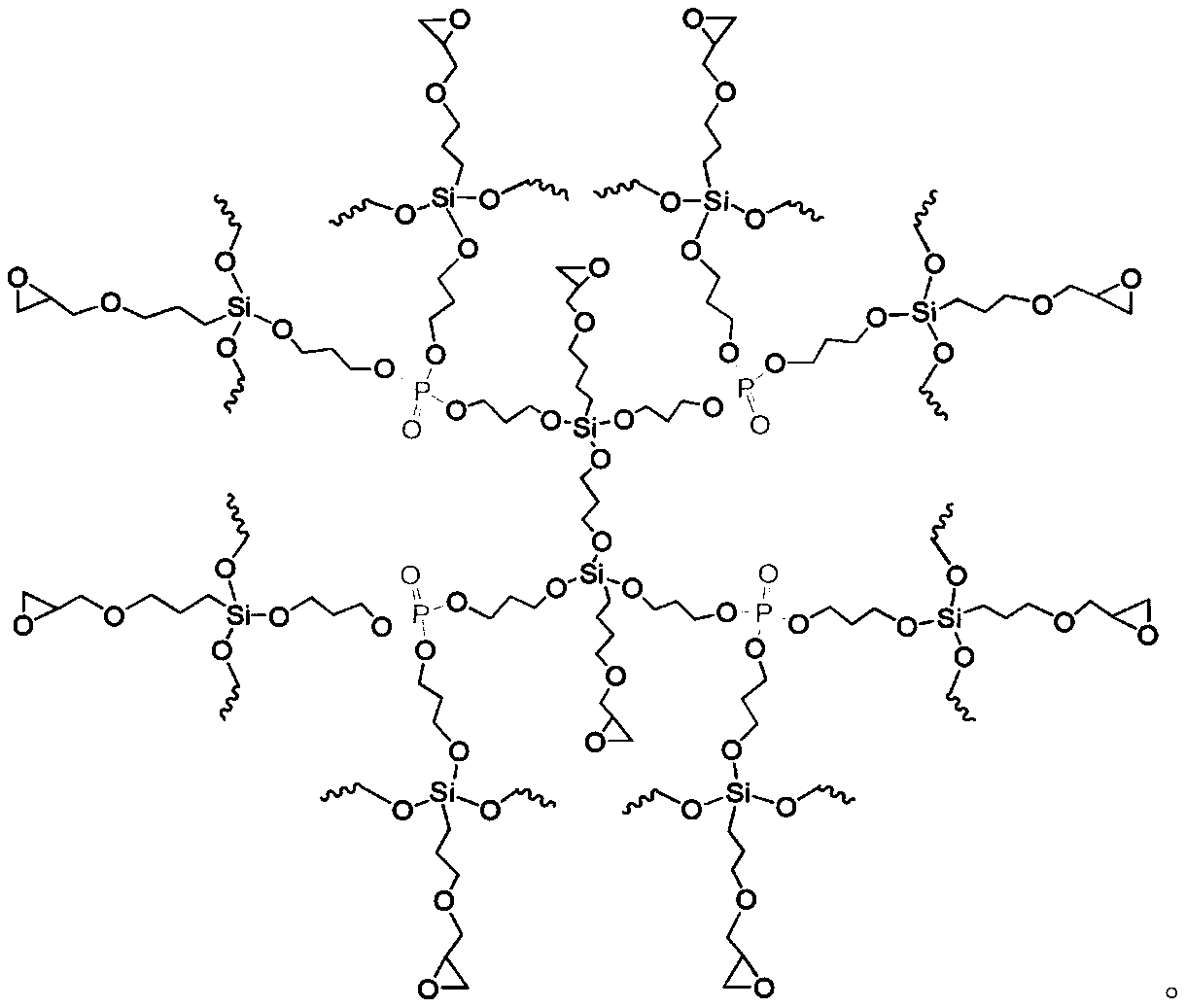

Hyperbranched silicon-phosphorus synergistic flame retardant modified epoxy resin and preparation method thereof

A technology of hyperbranched silicon phosphorus and epoxy resin, which is applied in the field of advanced polymer material science, can solve the problems of small functionality, unfavorable epoxy resin cross-linked network structure, and difficulty in meeting toughness requirements, and achieves improved toughness and excellent resistance. The effect of combustion effect and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Add γ-(2,3-epoxypropoxy)propyltrimethoxysilane, triethyl phosphate and 1,3-propanediol into a three-necked flask at a molar ratio of 1:1:4.375, under nitrogen protection Stirring in an oil bath, controlling the reaction temperature at 80-150° C., and reacting for 10-12 hours until no distillate is produced, to prepare phosphorus-containing hyperbranched polysiloxane.

[0032] Mix 60 parts of bisphenol A epoxy resin and 3 parts of phosphorus-containing hyperbranched polysiloxane, and stir at room temperature for 10-15 minutes to prepare a resin prepolymer. Then, add 50 parts of acid anhydride curing agent and 1 part of tertiary amine curing accelerator to the above prepolymer, stir for 5 to 10 minutes, pour it into a preheated mold, and put it in a vacuum oven at 80 to 100 ° C. , remove the air bubbles by vacuuming, put it into the blast drying oven for stage heating and curing, the curing process is 100~120°C / 2~4h+140~170°C / 2~3h, cooling, demoulding, and then at 170~200...

Embodiment 2

[0034] Add γ-(2,3-epoxypropoxy)propyltrimethoxysilane, triethyl phosphate and 1,3-propanediol into a three-necked flask at a molar ratio of 1:1:4.375, under nitrogen protection Stirring in an oil bath, controlling the reaction temperature at 80-150° C., and reacting for 10-12 hours until no distillate is produced, to prepare phosphorus-containing hyperbranched polysiloxane.

[0035] Mix 60 parts of bisphenol A epoxy resin and 5 parts of phosphorus-containing hyperbranched polysiloxane, and stir at room temperature for 10-15 minutes to prepare a resin prepolymer. Then, add 50 parts of acid anhydride curing agent and 1 part of tertiary amine curing accelerator to the above prepolymer, stir for 5 to 10 minutes, pour it into a preheated mold, and put it in a vacuum oven at 80 to 100 ° C. , remove the air bubbles by vacuuming, put it into the blast drying oven for stage heating and curing, the curing process is 100~120°C / 2~4h+140~170°C / 2~3h, cooling, demoulding, and then at 170~200...

Embodiment 3

[0037] Add γ-(2,3-epoxypropoxy)propyltrimethoxysilane, triethyl phosphate and 1,3-propanediol into a three-necked flask at a molar ratio of 1:1:4.375, under nitrogen protection Stirring in an oil bath, controlling the reaction temperature at 80-150° C., and reacting for 10-12 hours until no distillate is produced, to prepare phosphorus-containing hyperbranched polysiloxane.

[0038] Mix 70 parts of bisphenol A epoxy resin, add 3 parts of phosphorus-containing hyperbranched polysiloxane, and stir at room temperature for 10-15 minutes to prepare a resin prepolymer. Then, add 50 parts of acid anhydride curing agent and 1 part of tertiary amine curing accelerator to the above prepolymer, stir for 5 to 10 minutes, pour it into a preheated mold, and put it in a vacuum oven at 80 to 100 ° C. , remove the air bubbles by vacuuming, put it into the blast drying oven for stage heating and curing, the curing process is 100~120°C / 2~4h+140~170°C / 2~3h, cooling, demoulding, and then at 170~20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com