Cherry-mulberry fermented wine and preparation method thereof

A technology for fermenting wine and cherries, applied in the preparation of alcoholic beverages, biochemical equipment and methods, and methods based on microorganisms, etc., can solve problems such as unfavorable industrial production, high energy consumption, exhaust pollution, etc., and reduce methanol residues. , The effect of reducing the production of methanol and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1 A kind of cherry mulberry fermented wine

[0043] Prepared by the following steps:

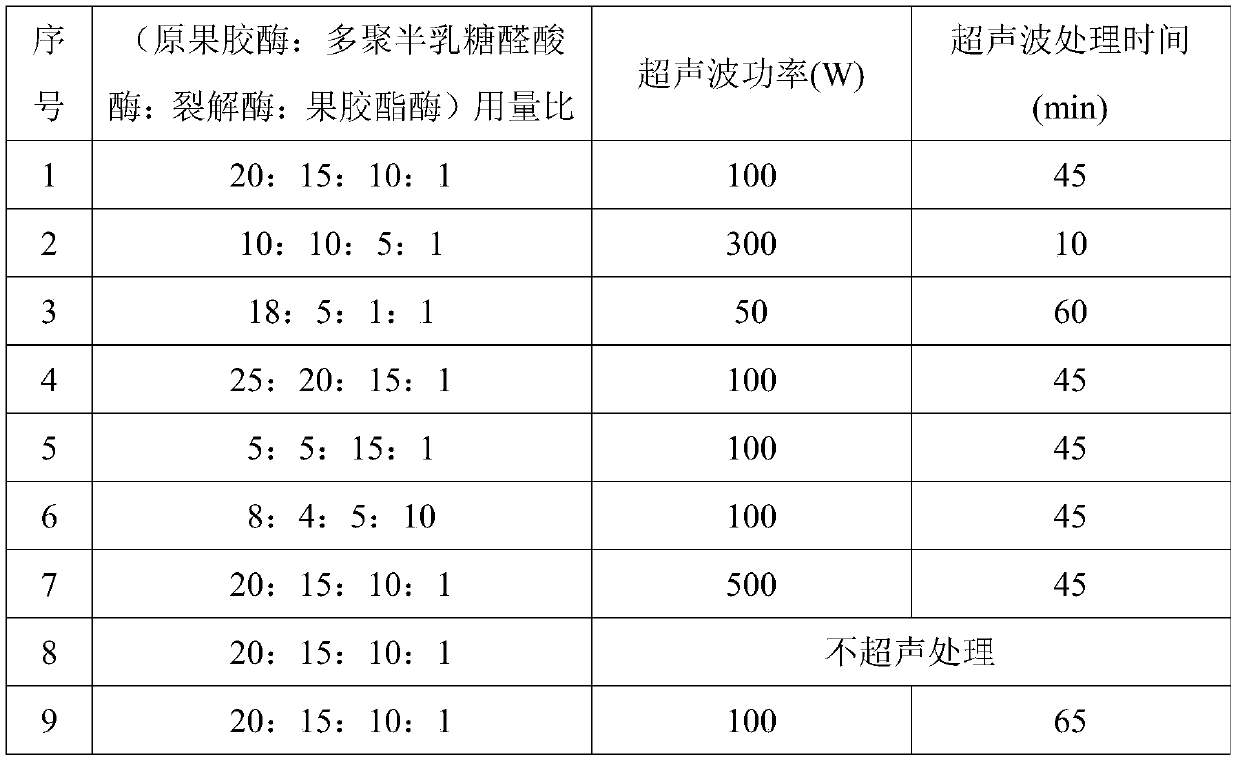

[0044] S1. Make cherries into pulp, add 150mg / L potassium metabisulfite, then add 100mg / L compound pectinase, treat with ultrasonic power 100W for 45min, perform enzymatic hydrolysis at 20°C for 8h, filter , get cherry juice;

[0045] S2. Make mulberries into a pulp, add 200mg / L potassium metabisulfite, then add 50mg / L compound pectinase, treat with ultrasonic power 100W for 45min, perform enzymolysis while ultrasonic treatment, enzymolyze at 20°C for 8h, filter , to get mulberry clear juice;

[0046]S3. Mix the clear cherry juice in step S1 and the clear mulberry juice in step S2 at a volume ratio of 1.75:1, add fructose syrup and white sugar with a weight ratio of 1:1 to adjust the sugar content so that the sugar content is 230g / L, and then inoculate and activate Saccharomyces cerevisiae OFD, the inoculum amount is 250mg / L, fermented at 20°C for 10 days, stirring the s...

Embodiment 2

[0049] Embodiment 2 A kind of cherry mulberry fermented wine

[0050] Prepared by the following steps:

[0051] S1. Make cherries into pulp, add 100mg / L potassium metabisulfite, then add 85mg / L compound pectinase, treat with ultrasonic power 300W for 10min, perform enzymatic hydrolysis while ultrasonic treatment, enzymolyze at 25°C for 5h, filter , get cherry juice;

[0052] S2. Make mulberries into a pulp, add 180mg / L potassium metabisulfite, then add 40mg / L compound pectinase, treat with ultrasonic power 300W for 10min, perform enzymolysis while ultrasonic treatment, enzymolyze at 25°C for 5h, filter , to get mulberry clear juice;

[0053] S3. Mix the clear cherry juice in step S1 and the clear mulberry juice in step S2 at a volume ratio of 1:1, add fructose syrup and white sugar with a weight ratio of 1:2 to adjust the sugar content so that the sugar content is 240g / L, and then inoculate and activate ADT of the beautiful fragrant yeast, the inoculum amount is 150mg / L, fe...

Embodiment 3

[0056] Embodiment 3 A kind of cherry mulberry fermented wine

[0057] Prepared by the following steps:

[0058] S1. Make cherries into pulp, add 160mg / L potassium metabisulfite, then add 120mg / L compound pectinase, treat with ultrasonic power 50W for 60min, perform enzymatic hydrolysis at 20°C for 10h, filter , get cherry juice;

[0059] S2. Make mulberries into pulp, add 190mg / L potassium metabisulfite, then add 20mg / L compound pectinase, treat with ultrasonic power 50W for 60min, perform enzymolysis while ultrasonic treatment, enzymolyze at 20°C for 10h, filter , to get mulberry clear juice;

[0060] S3. Mix the clear cherry juice in step S1 and the clear mulberry juice in step S2 at a volume ratio of 3:1, add fructose syrup and white sugar with a weight ratio of 1:0.5 to adjust the sugar content so that the sugar content is 210g / L, and then inoculate and activate Laffort F33 yeast, the inoculum amount is 300mg / L, ferment for 10 days at 25°C, and stir the skin dregs cap 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com