Lactobacillus rhamnosus 753 and application thereof, silage additive and silage

A technology of Lactobacillus rhamnosus and silage, applied in the agricultural field, can solve the problems of pungent smell, lower pH value, moldy silage, etc., and achieve good aerobic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Isolation and screening of strains

[0035] 1. Raw materials:

[0036] Corn: Whole-plant corn at the milky stage (from three varieties: Yayu 8, Zhongdan 808 and Duoyu 3);

[0037] Hybrid Pennisetum: Hybrid Pennisetum harvested when the height is greater than 1.5m (Guimu No. 1)

[0038] MRS liquid culture medium: Dissolve the raw materials (Table 1) in 1L of distilled water, autoclave at 121°C for 15 minutes, and cool down for later use.

[0039] MRS solid medium: Dissolve the raw materials (Table 1) in 1L of distilled water, add 15g of agar, pour it into a disposable petri dish, autoclave at 121°C for 15min, and cool it for later use.

[0040] Table 1 Medium Raw Materials

[0041] Raw Material Dosage Beefextract 10.00g Yeast Extract Yeastextract 5.00g Sodium acetate anhydrous 5.00g Peptone 10.00g K 2 HPO 4

2.00g Glucose 20.00g Tween-80Tween-80 1.00ml MgSO 4 .H 2 o

0.58g Ammonium citrate 2....

Embodiment 2

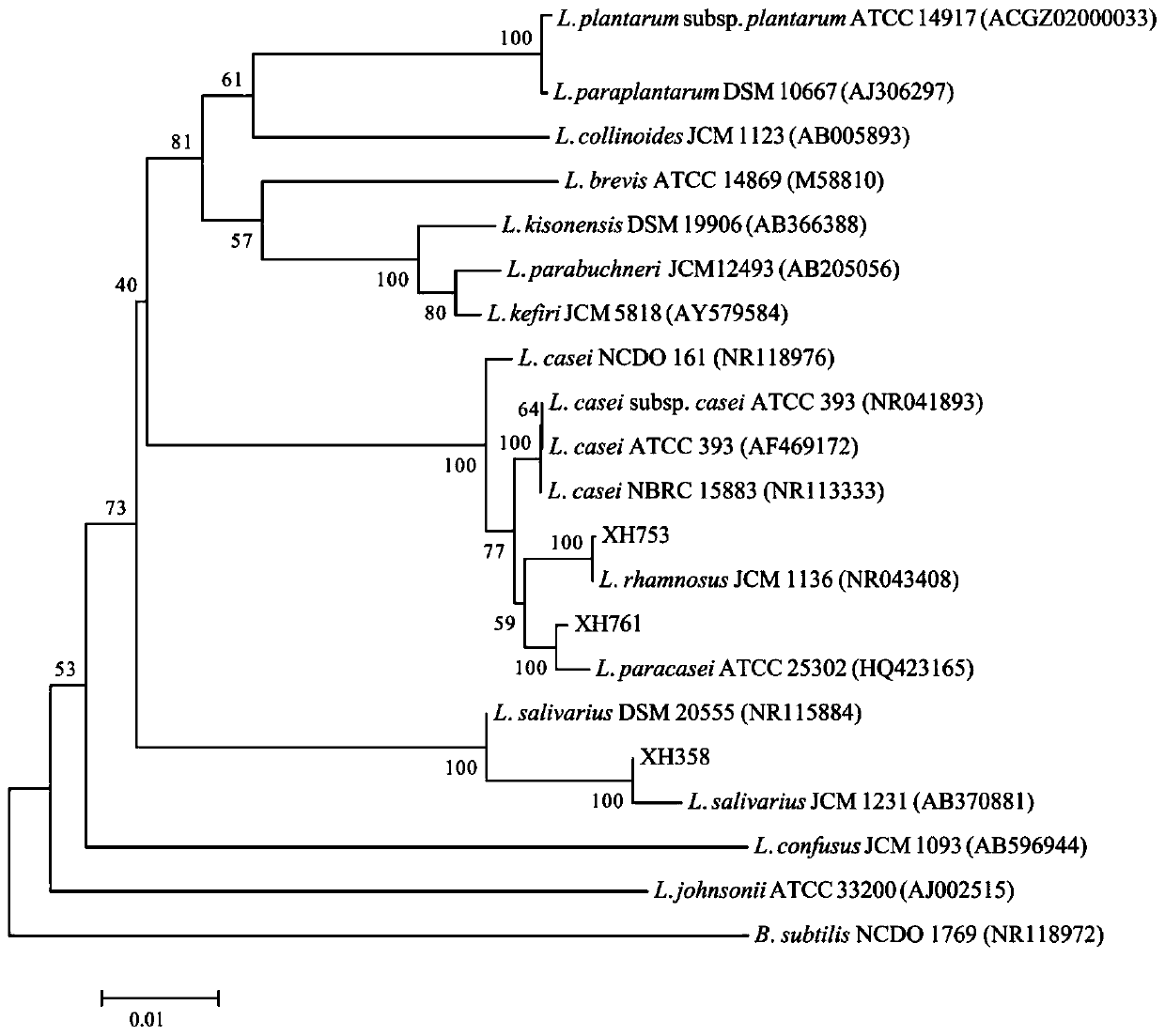

[0063] 2. Identification of strains

[0064] DNA extraction

[0065] Lactobacillus rhamnosus 753 was cultured overnight in 5 mL of MRS medium at 37 °C, centrifuged at 10,000 g for 5 min, and centrifuged in a clean 15 mL microcentrifuge with TE buffer (10 mmol L-1 tri-hcl, 0.1 mmol L-1 EDTA, pH 8.0). The cells were washed twice in the tube and centrifuged again. DNA extraction was performed using TIANamp Bacterial DNA Kit (DP302-02, Tiangen Biotech Co., Ltd., Beijing, China) according to the manufacturer's instructions. The DNA concentration of the strain was measured at 260 nm using a UV-Vis spectrophotometer (Shanghai Sunshine Hengping Scientific Instrument Co., Ltd., Shanghai). DNA extracted from the strains was stored at -20°C until use.

[0066] 16SrRNA Species Identification

[0067] The 16SrDNA coding region was amplified by PCR. Use 1 μL of diluted DNA as template for PCR reactions. PCR primers were 27f (5'-AGAGTTTGA TCC TGG CTCAG-3') and 1492r (5'-tacggctac CTTGT...

Embodiment 3

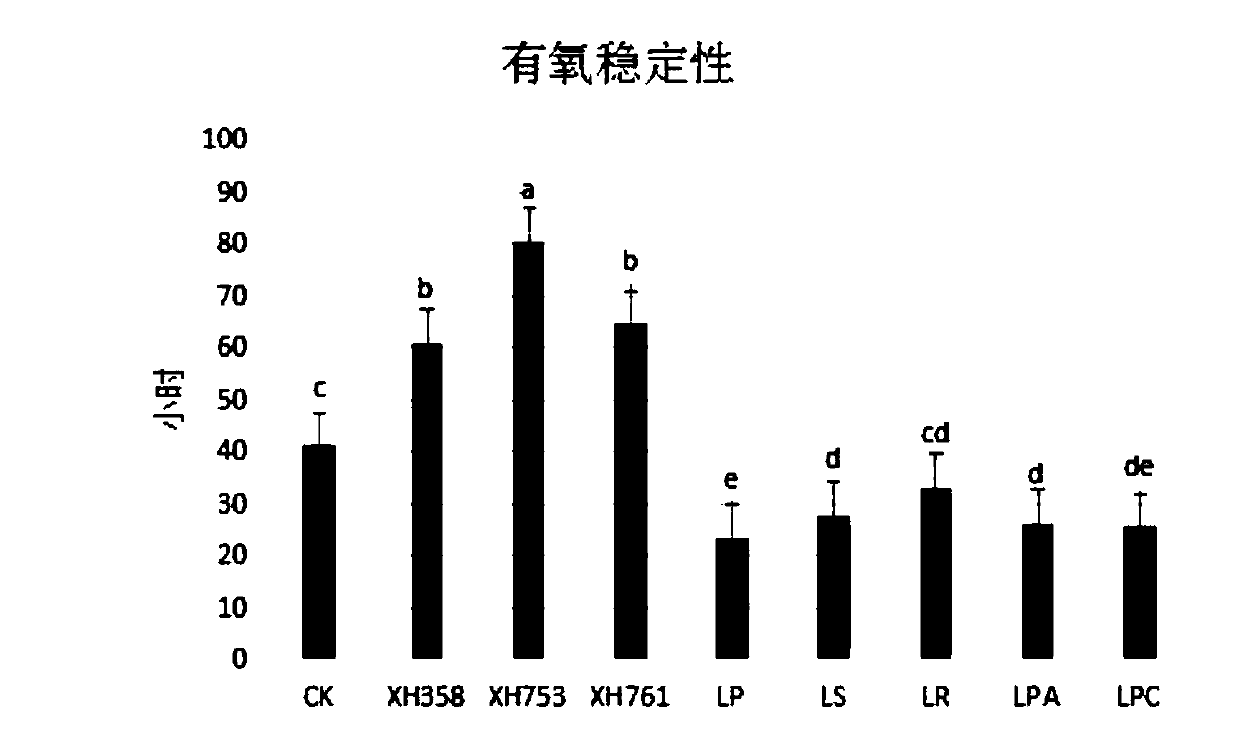

[0073] 3. Lactobacillus rhamnosus 753 (Lactobacillus rhamnosus) (silage corn, silage additive, silage preparation

[0074] Silage raw material: Whole plant corn harvested in the milk ripening stage at Sichuan Agricultural University Experimental Farm (Chongzhou, Sichuan, China)

[0075] experiment material;

[0076] The test materials included 3 screened lactic acid bacteria strains, 4 lactic acid bacteria standard strains, 1 commercial Lactobacillus plantarum (LPC) and 1 commercial Lactobacillus rhamnosus (LRC), and 2 commercial strains were purchased from Sichuan Gaofuji Biotechnology Co., Ltd. company.

[0077] (1) Three strains of lactic acid bacteria screened out

[0078] b. Lactobacillus salivarius 358 (XH358);

[0079] c. Lactobacillus rhamnosus 753 (XH753);

[0080] d. Lactobacillus paracasei 761 (XH761).

[0081] (2) 4 standard strains of lactic acid bacteria

[0082] a'. Lactobacillus plantarum (LP);

[0083] b'. Lactobacillus salivarius (LS);

[0084] c'. La...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com