Method for constructing super-hydrophobic corrosion-resistant conversion film on surface of magnesium-lithium alloy and magnesium-lithium alloy with super-hydrophobic corrosion resistance

A magnesium-lithium alloy and super-hydrophobic technology, applied in the coating process of metal materials, etc., can solve the problems of high price, environmental pollution, unfavorable promotion, etc., and achieve the goal of improving corrosion resistance, good corrosion resistance, and reducing contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

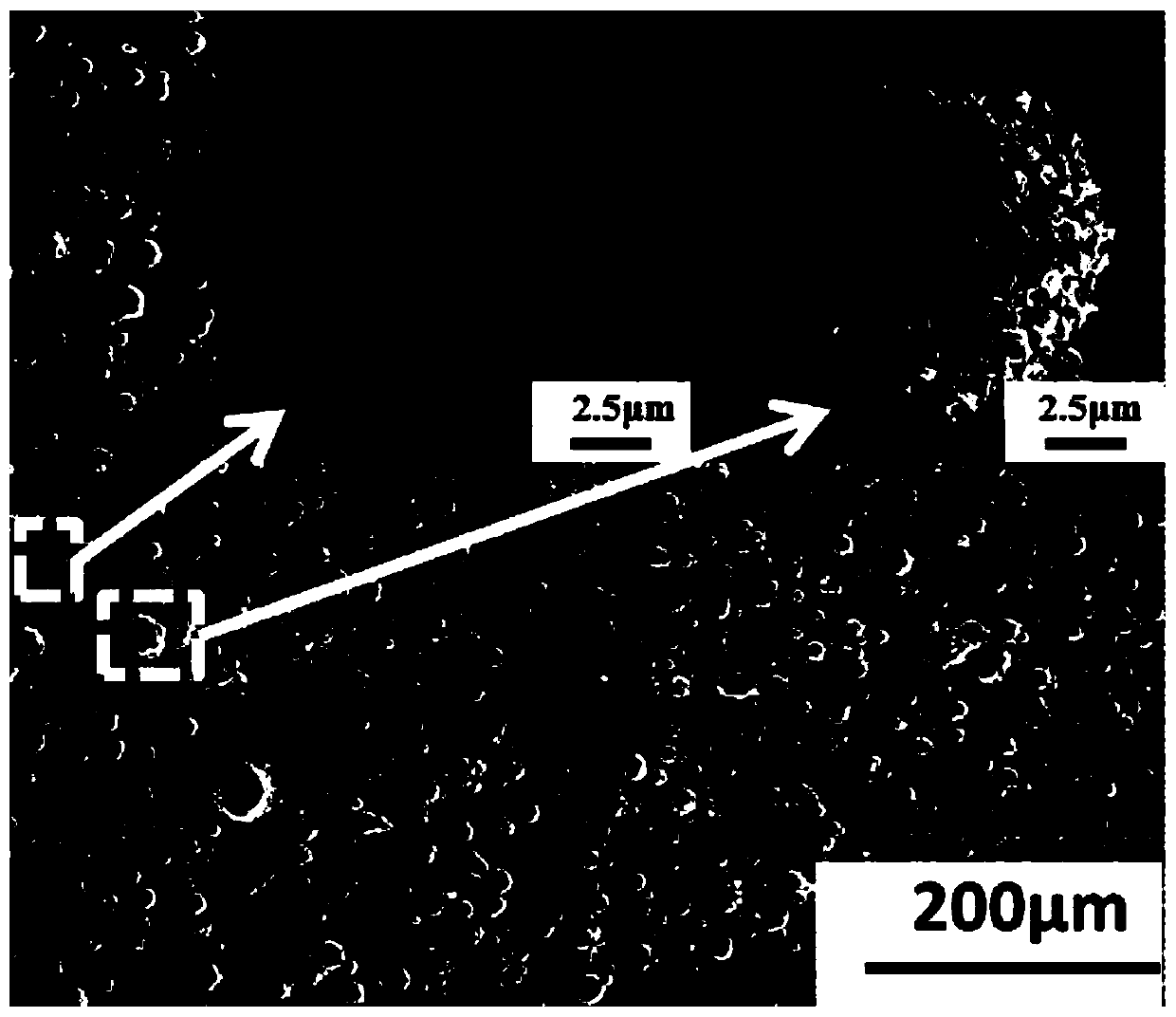

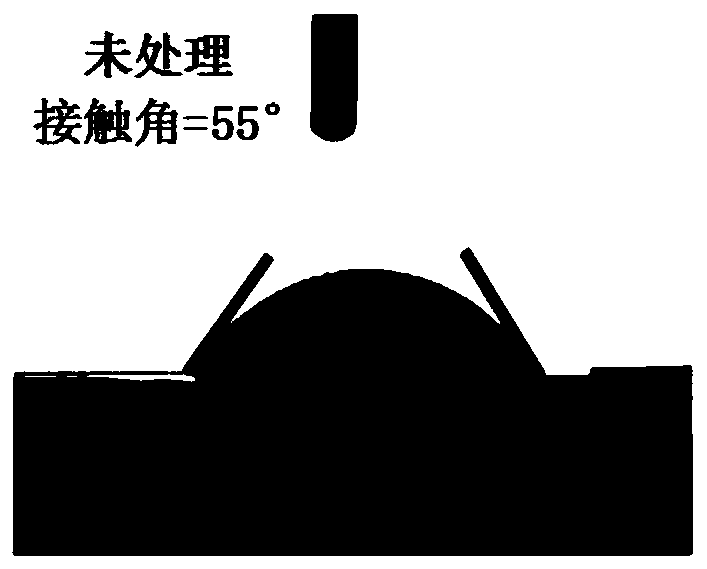

[0040] Process the Mg-9Li alloy into a 10mm×10mm×2mm cube, inlay it with epoxy resin, then polish it with 400, 600, 800, 1000, 1500 mesh sandpaper in turn, and then use 0.05μm alumina polishing powder to suspend The solution was mechanically polished, and finally ultrasonically cleaned with alcohol and acetone for 10 minutes respectively, and dried. Add stearic acid to 50mL of ethanol, add an equal volume of distilled water and stir at the same time to obtain a mixed solution (the concentration of magnesium stearate in the mixed solution is 0.01M); use a graduated cylinder to measure 70mL of the mixed solution and place it in a 100mL reaction In the kettle, put the processed samples into the reaction kettle, then place the reaction kettle in the electric furnace, keep it at 110°C for 2 hours, and finally, cool it to room temperature with the furnace, take it out and dry it.

[0041] Observation by scanning electron microscopy reveals that a conversion film has been constructed...

Embodiment 2

[0044] Process the Mg-9Li alloy into a 10mm×10mm×2mm cube, inlay it with epoxy resin, then polish it with 400, 600, 800, 1000, 1500 mesh sandpaper in turn, and then use 0.05μm alumina polishing powder to suspend The solution was mechanically polished, and finally ultrasonically cleaned with alcohol and acetone for 10 minutes respectively, and dried. Add stearic acid in 50mL ethanol, add distilled water of equal volume and stir simultaneously, obtain mixed liquor (the concentration of magnesium stearate in the mixed liquor is 0.01M); In a 100mL reactor, put the treated sample into the reactor, then place the reactor in an electric furnace, keep it at 130°C for 2 hours, and finally, cool it to room temperature with the furnace, take it out and dry it.

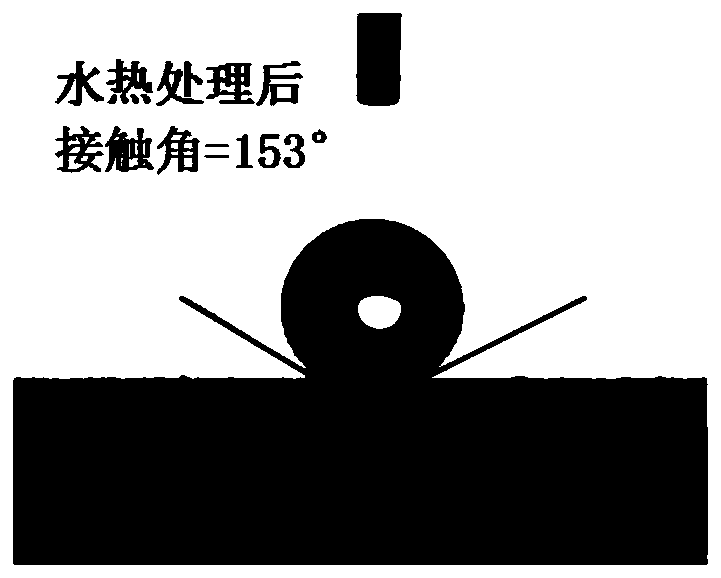

[0045] Observation by scanning electron microscopy shows that a conversion film is formed on the surface of the magnesium-lithium alloy. The conversion film is composed of a spherical substructure and a sheet-like substructure. ...

Embodiment 3

[0047] The difference from Example 2 is that the temperature of the hydrothermal reaction is 120°C.

[0048] Observation by scanning electron microscopy shows that a conversion film is formed on the surface of the magnesium-lithium alloy. The conversion film is composed of a spherical substructure and a sheet-like substructure. The angle is 151°. Through electrochemical tests, the AC impedance of the magnesium-lithium alloy with a superhydrophobic conversion film is 5100 ohm cm 2 (Such as Figure 4 shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Ac impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com