Method for producing hydrogen by syntrophism and interaction of fermentative hydrogen-producing bacteria and electroactive bacteria

An electroactive and bacterial technology is applied in the field of hydrogen production where fermentative hydrogen-producing bacteria and electroactive bacteria interact with each other. , Improve the efficiency of hydrogen production and reduce the effect of metabolic inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0019] Specific embodiment 1: This embodiment provides a method for utilizing Harbin ethanologens (Ethanoligenens harbinense) W1 and Geobacter (Geobacter sulfurreducens) PCA intertrophy interaction and interspecific electron transfer to efficiently produce hydrogen. The operation steps are as follows:

[0020] (1) Cultivate Harbin Ethanologenus W1 by anaerobic culture method: high-purity N with a purity of 99.99% after high temperature boiling 2 The liquid medium A after aeration and high-temperature and high-pressure steam sterilization was used to cultivate Harbin ethanologenic bacteria W1, and the anaerobic bottle inoculated with Harbin ethanologenic bacteria W1 was placed in a constant temperature shaker at 35°C and 170rpm for shaking culture. After 46 hours, In the anaerobic bottle, a light yellow turbid bacterial liquid accompanied by white flocculent bacterial cells was formed, centrifuged at a speed of 5000r / h for 10 minutes, discarded the supernatant, and obtained the...

specific Embodiment approach 2

[0031] Embodiment 2: In this embodiment, a method for producing hydrogen by Ethanoligenensharbinense W1 is provided. The main difference between Embodiment 2 and Embodiment 1 is that only Ethanologens Harbin W1 is inoculated in step (3). The other culture conditions and steps are the same. After 1.5 hours of culture, gas production begins, and the maximum hydrogen production rate is 32.8mL / L-medium h in about 35 hours. The final hydrogen production rate is 1.08mol-hydrogen / mol-glucose.

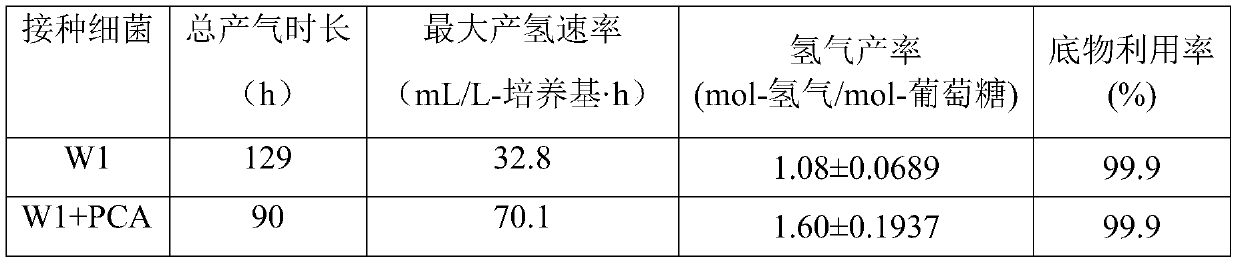

[0032] The hydrogen production effect of specific embodiment 1 and specific embodiment 2 is compared in the following table,

[0033]

[0034] It can be seen from the above table that the co-cultivation of Harbin Ethanologenus W1 and Geobacter PCA can significantly shorten the gas production time, and the maximum hydrogen production rate is significantly increased, and has no adverse effect on the substrate utilization rate. The co-cultivation can obtain higher Hydrogen yield.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com