A kind of high thermal conductivity polyimide multilayer composite film and preparation method thereof

A polyimide, multi-layer composite technology, applied in chemical instruments and methods, layered products, flat products, etc., can solve the problems of uneven performance, film flexibility and toughness decline, etc. Excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

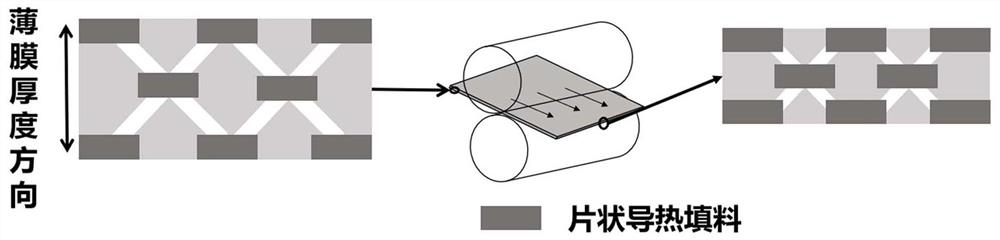

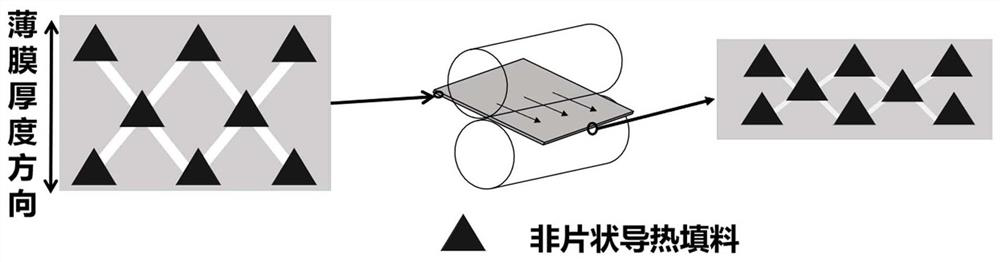

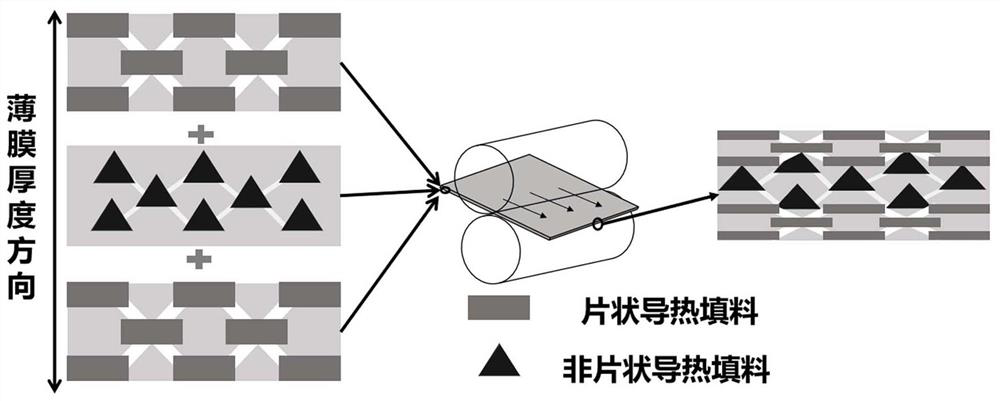

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of a high thermal conductivity polyimide multilayer composite film, comprising the steps of:

[0038] (1) 8.615g diamine 4,4 , - Diaminodiphenyl ether is dissolved in 82g N, N-dimethylacetamide organic solvent, then add 9.385g PMDA in the diamine solution, 9.385g PMDA is respectively according to 50%, 20%, 20%, 8% Adding to the reaction solvent four times, with an interval of 0.5h each time, the remaining 2% PDMA adjusts the viscosity of the system so that the viscosity of the system reaches 50000 MPa·s to obtain a polyamic acid solution;

[0039] (2) Add 3.15g of boron nitride, 3.15g of alumina, and 0.063g of PVP k60 dispersant into the polyamic acid solution, and stir mechanically for about 3 hours to obtain a uniformly mixed solution. Defoaming treatment is carried out under 1Mpa to obtain a polyimide solution containing thermally conductive fillers;

[0040](3) After laying the film with the polyamic acid solution treated with defoaming, put i...

Embodiment 2

[0048] A preparation method of a high thermal conductivity polyimide multilayer composite film, comprising the steps of:

[0049] (1) Diamine 8.615g 4,4 , -Diaminodiphenyl ether was dissolved in 82g of N,N-dimethylacetamide organic solvent, and then 9.385g of PDMA was added to the diamine solution, PMDA was divided into 50%, 20%, 20%, and 8% and added four times In the reaction solvent, each interval is 0.5h, and the remaining 2% PDMA adjusts the viscosity of the system so that the viscosity of the system reaches 50000 MPa·s, and a polyamic acid solution is obtained;

[0050] (2) Add 3.15g of boron nitride, 3.15g of alumina, and 0.063g of PVP k60 dispersant into the polyamic acid solution, and stir mechanically for about 3 hours to obtain a uniformly mixed solution. Defoaming treatment is carried out under 1Mpa to obtain a polyimide solution containing thermally conductive fillers;

[0051] (3) After laying the film with the polyamic acid solution treated with defoaming, put...

Embodiment 3

[0058] A preparation method of a high thermal conductivity polyimide multilayer composite film, comprising the steps of:

[0059] (1) 8.615g diamine 4,4 , - Dissolve diaminodiphenyl ether in 82g of N,N-dimethylacetamide organic solvent, then add 9.385g of PDMA to the diamine solution, PDMA is divided into 50%, 20%, 20%, and 8% in four additions In the reaction solvent, each interval is 0.5h, and the remaining 2% PDMA adjusts the viscosity of the system so that the viscosity of the system reaches 50000 MPa·s, and a polyamic acid solution is obtained;

[0060] (2) Add 3.15g of boron nitride, 3.15g of alumina, and 0.063g of MOK5040 dispersant into the polyamic acid solution, and stir mechanically for about 3 hours to obtain a well-mixed mixture. Put the mixture into a vacuum oven at -1Mpa Carry out defoaming treatment under, make the polyimide solution containing thermally conductive filler;

[0061] (3) After laying the film with the polyamic acid solution treated with defoami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com