Diborane synthesis system and method thereof

A synthesis method and technology of diborane, applied in the field of diborane synthesis system, can solve the problems of difficulty in use, unreasonable design, and low extraction purity, and achieve the effect of reducing investment and improving overall performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

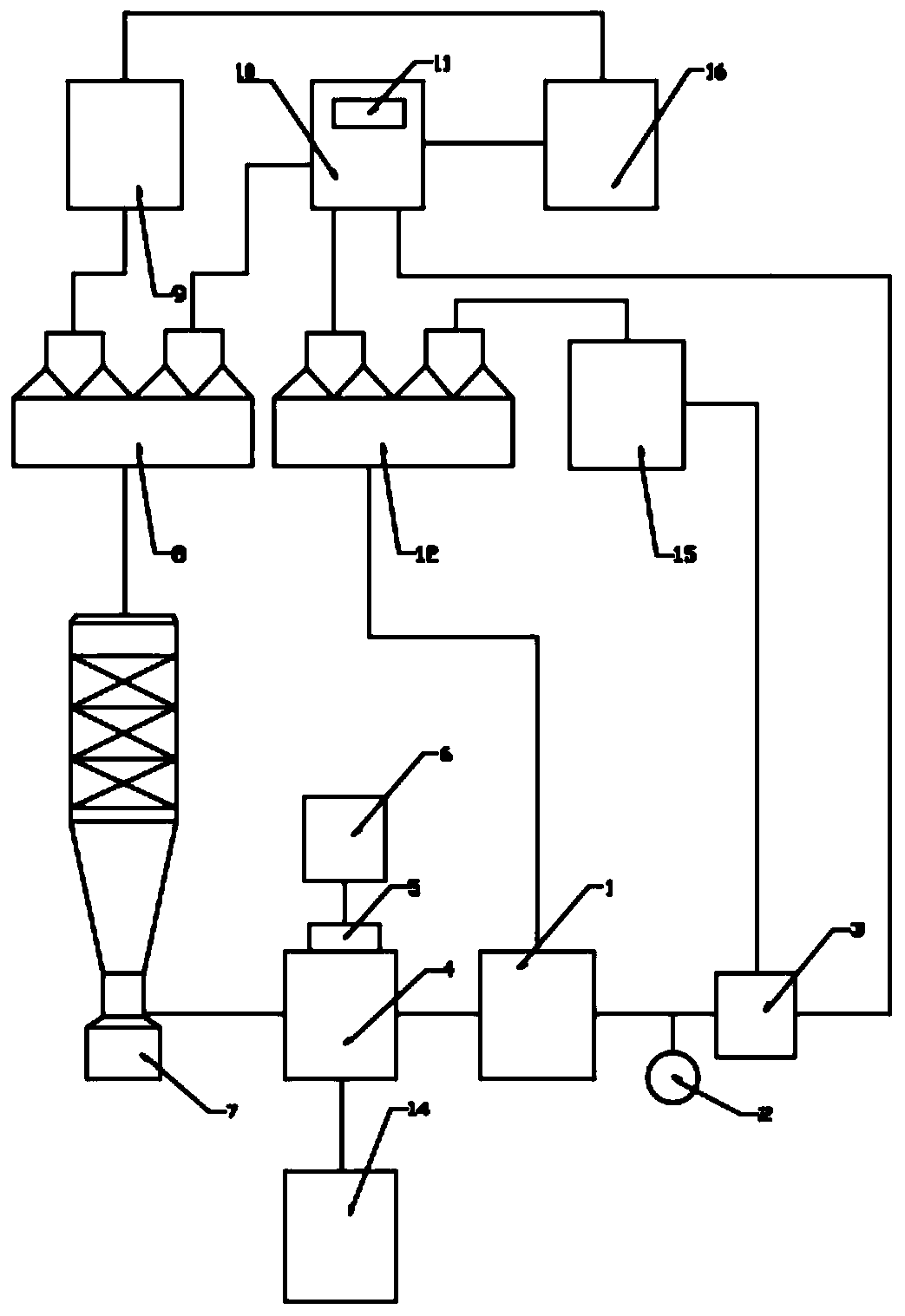

[0029] Such as figure 1 As shown, a diborane synthesis system includes a reactor 1, and the reactor 1 is provided with an air inlet, a first air outlet, a first feeding inlet, a second feeding inlet, and a material outlet. The air inlet pipe is connected with Nitrogen bottle 2 and gas mixing device 3, the discharge port pipe is connected with the feed port of the reactor 4, the reactor 4 is provided with a discharge port, a dripping device 5 and a second gas outlet, and the discharge port pipe is connected with a treatment tank 14. The pipe of the dripping device 5 is connected with the acid tank 6, the second gas outlet pipe is connected with the adsorption tower 7, the top pipe of the adsorption tower 7 is connected with the first cold hydrazine 8, and the first cold hydrazine 8 pipe is connected with the first gas collection tank 9 and the liquid collection tank 10, the liquid collection tank 10 is provided with a heating device 11, the gas outlet pipe is connected with a se...

Embodiment 2

[0039] Diborane synthesis system, the same as in Example 1.

[0040] The method for synthesizing diborane includes the following steps:

[0041] Step 1: Pass inert gas into the reactor 1 to replace the internal environment, set the temperature of the reactor 1 to 20℃, add dimethyl ether polyethylene glycol after 12 minutes of ventilation, stir, and then add it to the reactor 1 Solid sodium borohydride, continue to stir, so that the sodium borohydride and dimethyl ether polyethylene glycol are mixed uniformly;

[0042] Step 2: Pass the mixture gas of diborane and nitrogen into the reactor 1 in step 1 according to the amount of substance 2:3. The inlet speed of diborane gas is 50g / min. The ratio of the amount of substances is 2:1 to generate intermediates and mixed waste gas, and the mixed waste gas is passed into the second cold hydrazine 12 for separation;

[0043] Step 3: Pass the intermediate in step 2 into the reactor 4, and then slowly drop sulfuric acid into the reactor 4 while ...

Embodiment 3

[0048] Diborane synthesis system, the same as in Example 1.

[0049] The method for synthesizing diborane includes the following steps:

[0050] Step 1: Pour inert gas into the reactor 1 to replace the internal environment, set the temperature of the reactor 1 to 40℃, add dimethyl ether polyethylene glycol after 15 minutes of ventilation, stir, and then add it to the reactor 1 Solid sodium borohydride, continue to stir, so that the sodium borohydride and dimethyl ether polyethylene glycol are mixed uniformly;

[0051] Step 2: Pass the mixture gas of diborane and nitrogen into the reactor 1 in step 1 according to the amount of substance 2:3. The inlet speed of diborane gas is 50g / min. The ratio of the amount of substances is 2:1 to generate intermediates and mixed waste gas, and the mixed waste gas is passed into the second cold hydrazine 12 for separation;

[0052] Step 3: Pass the intermediate in step 2 into the reactor 4, and then slowly drop sulfuric acid into the reactor 4 while ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com