Damp-proof heat preservation layer material for floor, and preparation method of damp-proof heat preservation layer material

A technology for thermal insulation layer and floor, applied in the field of foam materials, can solve the problems of poor thermal insulation and moisture-proof performance, and achieve the effects of good moisture-proof effect, light weight and low water absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A floor moisture-proof insulation layer material, made of raw materials including the following parts by weight:

[0037] Ethylene-vinyl acetate copolymer 70-85 parts, methyl vinyl phenyl silicone rubber 14-19 parts, elastomer 18-23 parts, dimethylsiloxane-oxyethylene copolymer 6-9 parts, expanded perlite 4-7 parts of powder, 2-4 parts of aluminum silicate fiber, 1.7-2.4 parts of foaming agent, 0.6-0.8 parts of auxiliary foaming agent, 4-6 parts of other additives;

[0038] The foaming agent is an AC foaming agent; the auxiliary foaming agent is a mixture of zinc diacrylate and zinc diethyldithiocarbamate.

[0039] Preferably, the floor moisture-proof insulation layer material is made of the following raw materials in parts by weight: 78 parts of ethylene-vinyl acetate copolymer, 16.6 parts of methyl vinyl phenyl silicone rubber, 20.5 parts of elastomer, dimethyl silicone 7.6 parts of alkane-oxyethylene copolymer, 5.2 parts of expanded perlite powder, 3 parts of alumin...

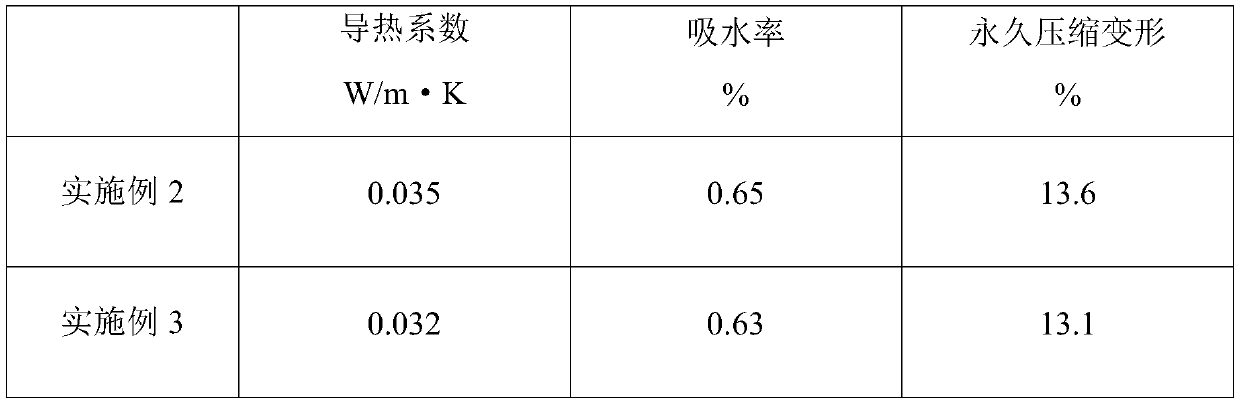

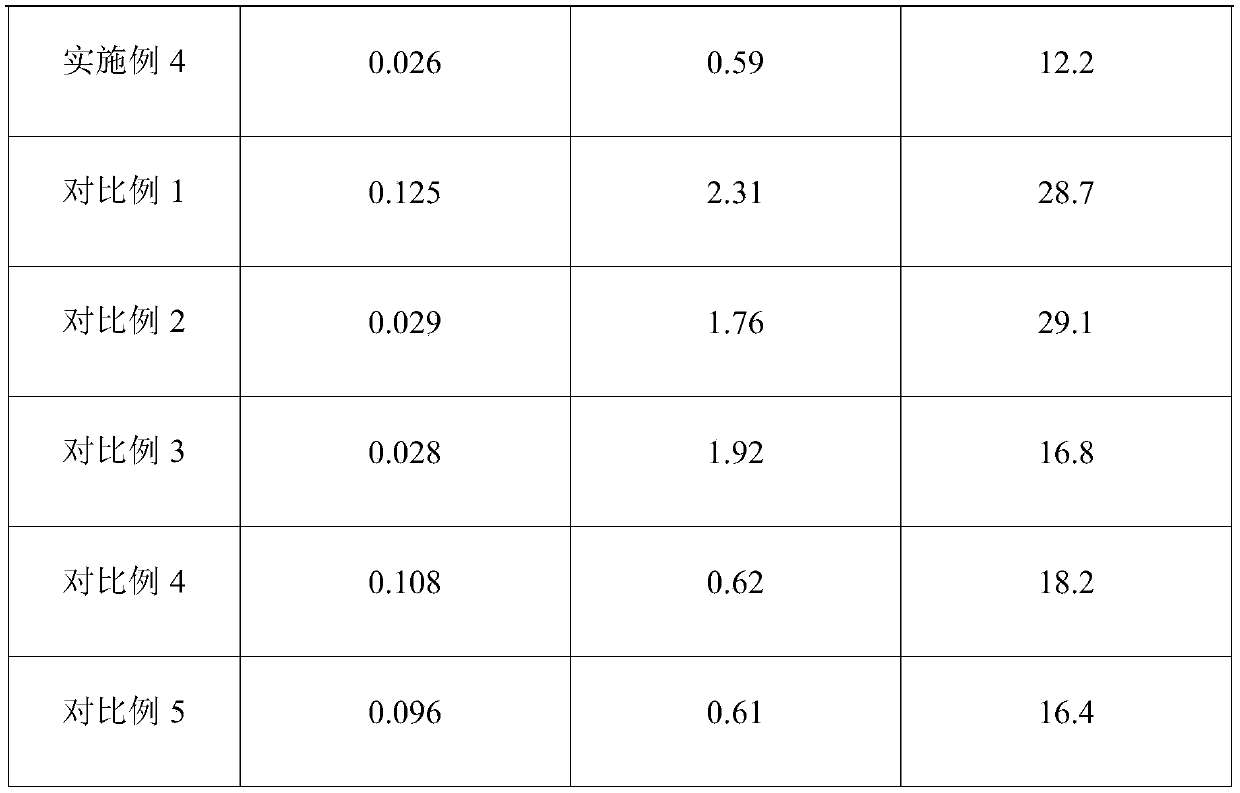

Embodiment 2

[0054] A floor moisture-proof insulation layer material, made of raw materials including the following parts by weight:

[0055] 70 parts of ethylene-vinyl acetate copolymer, 14 parts of methyl vinyl phenyl silicone rubber, 18 parts of elastomer, 6 parts of dimethylsiloxane-oxyethylene copolymer, 4 parts of expanded perlite powder, aluminum silicate fiber 2 parts, 1.7 parts of foaming agent, 0.6 parts of auxiliary foaming agent, 4 parts of other additives;

[0056] The foaming agent is an AC foaming agent; the auxiliary foaming agent is a mixture of zinc diacrylate and zinc diethyldithiocarbamate.

[0057] In this embodiment, the mass ratio of zinc diacrylate and zinc diethyldithiocarbamate in the mixture of zinc diacrylate and zinc diethyldithiocarbamate is 1:0.75.

[0058] In this embodiment, the elastomer is a mixture of oxidized polyethylene and polyether polyurethane elastomer.

[0059] In this embodiment, the mass ratio of the oxidized polyethylene and the polyether po...

Embodiment 3

[0071] A floor moisture-proof insulation layer material, made of raw materials including the following parts by weight:

[0072] 85 parts of ethylene-vinyl acetate copolymer, 19 parts of methyl vinyl phenyl silicone rubber, 23 parts of elastomer, 9 parts of dimethylsiloxane-oxyethylene copolymer, 7 parts of expanded perlite powder, aluminum silicate fiber 4 parts, 2.4 parts of foaming agent, 0.8 parts of auxiliary foaming agent, 6 parts of other additives;

[0073] The foaming agent is an AC foaming agent; the auxiliary foaming agent is a mixture of zinc diacrylate and zinc diethyldithiocarbamate.

[0074] In this embodiment, the mass ratio of zinc diacrylate and zinc diethyldithiocarbamate in the mixture of zinc diacrylate and zinc diethyldithiocarbamate is 1:0.85.

[0075] In this embodiment, the elastomer is a mixture of oxidized polyethylene and polyether polyurethane elastomer.

[0076] In this embodiment, the mass ratio of the oxidized polyethylene and the polyether po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com