Antistatic TPU belt

An antistatic and antistatic agent technology, applied in the field of conveyor belts, can solve the problems affecting the tensile strength and impact strength of TPU conveyor belts, the difficulty of TPU glue-coated lamination, and the reduction of the performance of TPU conveyor belts, etc., to achieve antistatic effects Good, improve the antistatic ability, improve the effect of electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

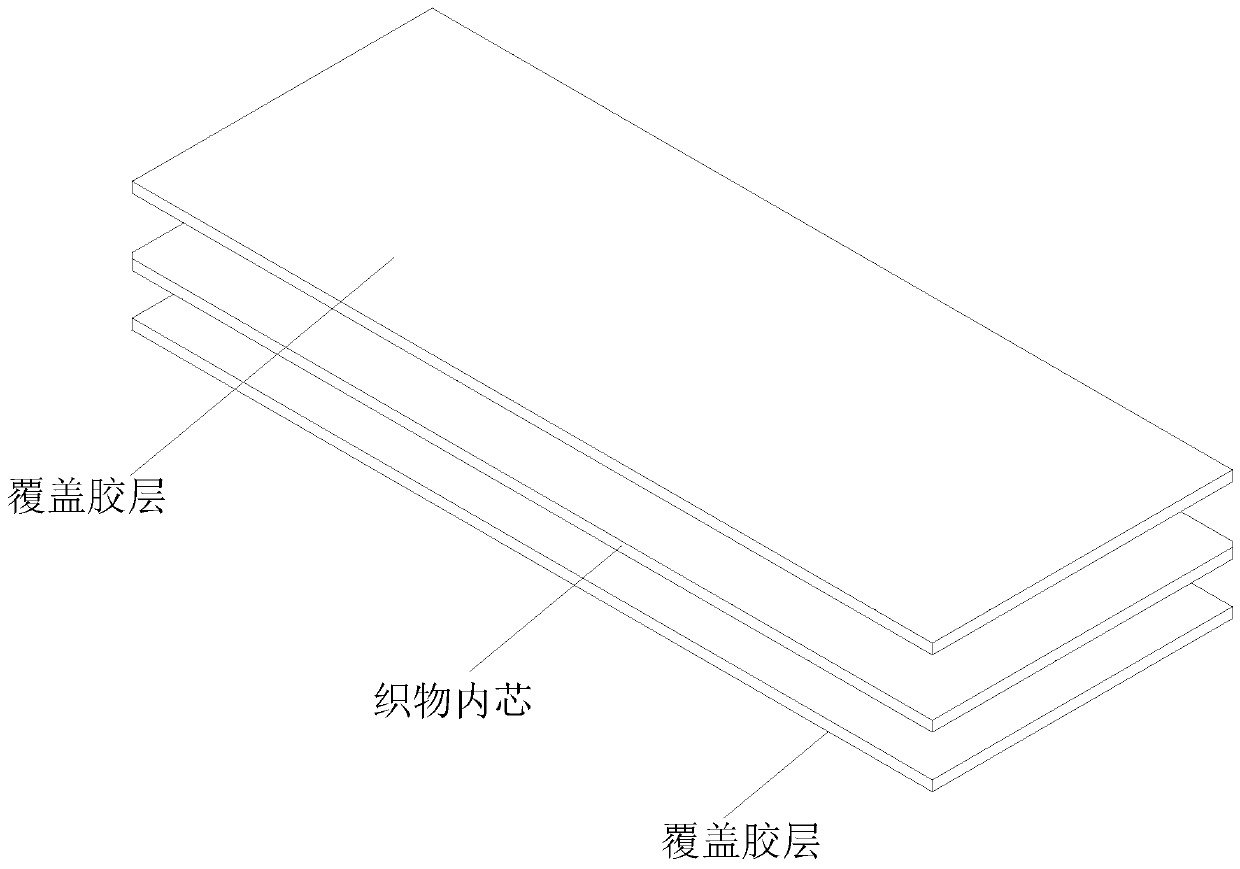

[0047] see figure 1 , the present invention provides the following technical solutions: an antistatic TPU belt, including a fabric inner core and a covering rubber layer;

[0048] The inner core of the fabric is composed of warp and weft, and the warp and weft are woven one by one according to the plain weave method;

[0049] Warp threads consist of polyester or cotton fibers or aramid and polyamide fibers;

[0050] The weft is composed of Ninon-based conductive fiber, hollow glass fiber and polypropylene fiber;

[0051] The cover adhesive layer comprises the following components in parts by weight:

[0052] 56 parts of TPU resin;

[0053] 4 parts of antistatic agent;

[0054] 3 parts of wear-resistant conductive carbon black;

[0055] 3 parts softener;

[0056] 12 parts of plasticizer;

[0057] Anti-aging agent 2 parts;

[0058] 2 parts epoxy resin;

[0059] 2 parts of sulfonic acid aromatic polymer;

[0060] 3 parts silicate;

[0061] 22 parts of PVC resin.

[00...

Embodiment 2

[0079] An antistatic TPU belt, including a fabric inner core and a covering glue layer;

[0080] The inner core of the fabric is composed of warp and weft, and the warp and weft are woven one by one according to the plain weave method;

[0081] Warp threads consist of polyester or cotton fibers or aramid and polyamide fibers;

[0082] The weft is composed of Ninon-based conductive fiber, hollow glass fiber and polypropylene fiber;

[0083] The cover adhesive layer comprises the following components in parts by weight:

[0084] 60 parts of TPU resin;

[0085] 5 parts of antistatic agent;

[0086] 3 parts of wear-resistant conductive carbon black;

[0087] 2 parts softener;

[0088] 11 parts of plasticizer;

[0089] Anti-aging agent 2 parts;

[0090] 2 parts of epoxy resin;

[0091] 3 parts of sulfonic acid aromatic polymer;

[0092] Silicate 2 parts;

[0093] 25 parts of PVC resin.

[0094] Specifically, the antistatic agent is trihydroxyethylmethyl quaternary ammoni...

Embodiment 3

[0111] An antistatic TPU belt, including a fabric inner core and a covering glue layer;

[0112] The inner core of the fabric is composed of warp and weft, and the warp and weft are woven one by one according to the plain weave method;

[0113] Warp threads consist of polyester or cotton fibers or aramid and polyamide fibers;

[0114] The weft is composed of Ninon-based conductive fiber, hollow glass fiber and polypropylene fiber;

[0115] The cover adhesive layer comprises the following components in parts by weight:

[0116] 65 parts of TPU resin;

[0117] 5 parts of antistatic agent;

[0118] Wear-resistant conductive carbon black 4 parts;

[0119] 4 parts softener;

[0120] 12 parts of plasticizer;

[0121] 1 part anti-aging agent;

[0122] 2 parts of epoxy resin;

[0123] 4 parts of sulfonic acid aromatic polymer;

[0124] 3 parts silicate;

[0125] 28 parts of PVC resin.

[0126] Specifically, the antistatic agent is trihydroxyethylmethyl quaternary ammonium m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com