A nitrogen-doped metal oxide gas-sensing material, gas-sensing element, preparation method and application thereof

A technology of gas-sensitive materials and oxides, applied in tin oxide, material resistance, analytical materials, etc., can solve problems such as high working temperature, poor selectivity, and limited applications, and achieve high sensitivity, increased quantity, high sensitivity and selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] In another specific embodiment of the present invention, the preparation method of the above-mentioned metal oxide material is provided, including: uniformly mixing a metal salt and a surfactant with an organic solvent, and solvothermally synthesizing a metal oxide precursor material; the metal oxide The precursor material is separated, dried and calcined to obtain metal oxide porous nanospheres.

[0040] In yet another specific embodiment of the present invention, a method for preparing the above-mentioned nitrogen-doped metal oxide gas-sensing material is provided, the method comprising:

[0041] (1) Dissolving the metal salt raw material and the surfactant in an organic solvent; subjecting the obtained clarified liquid to a compound reaction under high temperature and high pressure conditions to obtain a metal oxide precursor.

[0042] (2) The product obtained in step (1) is centrifuged, washed with methanol, dried and then calcined to obtain metal oxide porous nanos...

Embodiment 1

[0064] 1. Nitrogen-doped metal oxide porous nanosphere gas-sensing material and its preparation

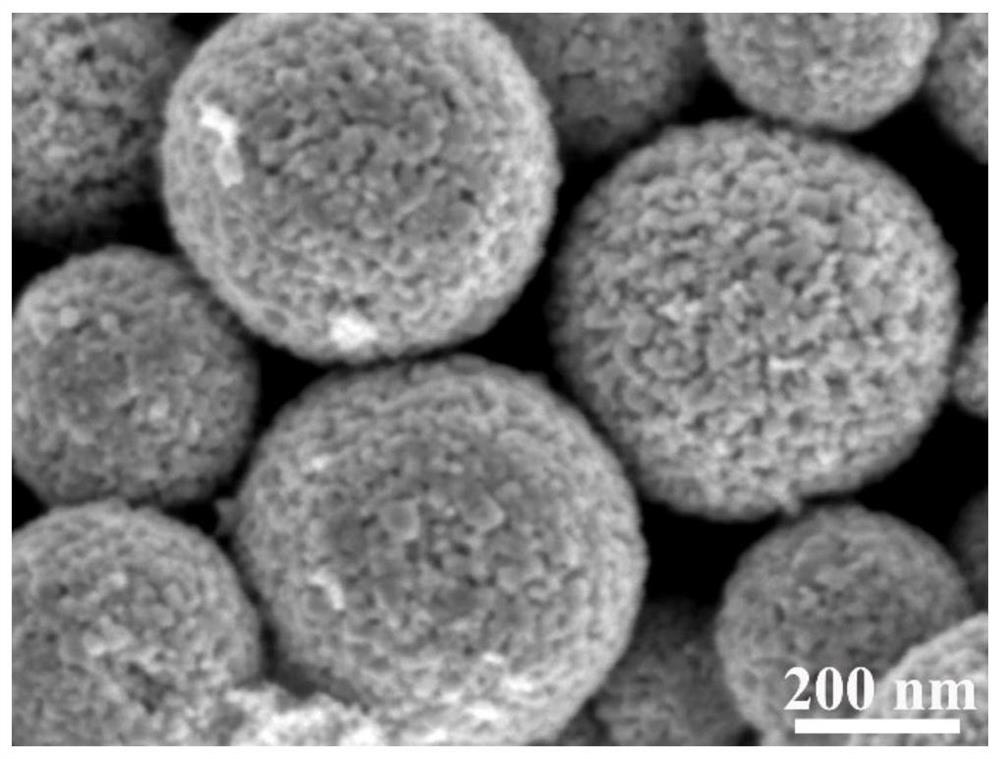

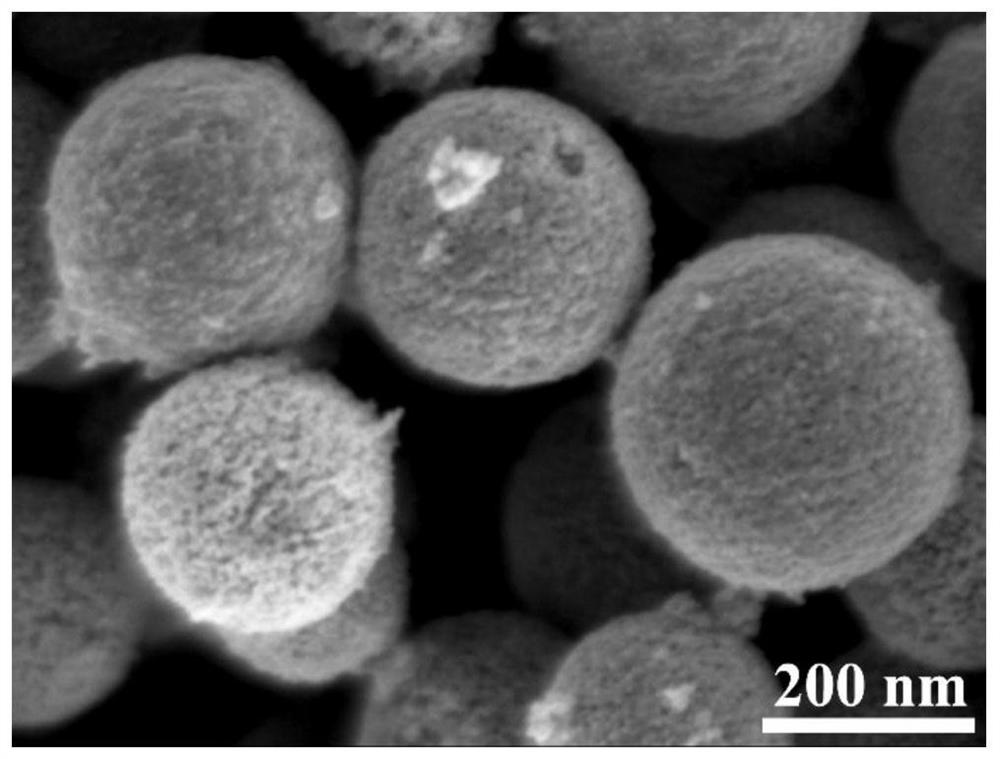

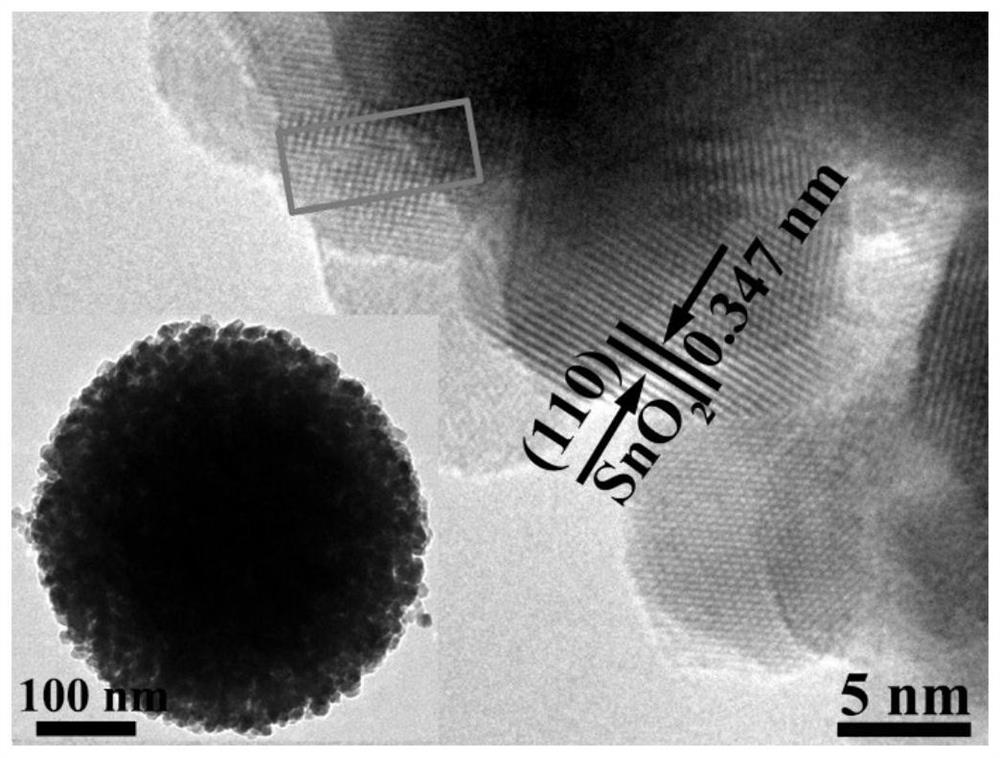

[0065] A low-concentration NO 2 Oxygen vacancies modified metal oxide gas sensing materials for gas detection, the metal oxide is SnO 2 Porous nanospheres; SnO 2 The porous nanospheres are placed in a tube furnace, calcined at different temperatures in an atmosphere of nitrogen provided by a nitrogen source, and the surface of the metal oxide is subjected to different degrees of nitrogen doping treatment. The nitrogen-doped metal oxide is a porous nanosphere composed of small particles, the diameter of the ball is 300-700nm, and the particle size is 10-30nm.

[0066] Preparation steps:

[0067] (1) Add 0.42g of tin tetrachloride and 0.5g of polyvinylpyrrolidone into 60ml of methanol solution and stir until they are completely dissolved. The stirred clear liquid is placed in a high-pressure reactor and heated to 180°C for 3 hours. A compound reaction occurs under high pressure,...

Embodiment 2

[0076] Example 2 Gas-sensitive detection of nitrogen-doped metal oxides prepared by calcining at different temperatures under the condition that the nitrogen-containing source provides nitrogen

[0077] As described in Example 1, the difference is that the calcination temperature of the metal oxide porous nanospheres in the nitrogen-containing atmosphere in step (1) is 100°C, 300°C and 400°C. At 80℃, 5ppm NO 2 Gas sensitivity test results under gas conditions are as follows: Figure 7 As shown, it can be seen from the figure that with the increase of calcination temperature, the gas-sensing properties of nitrogen-doped metal oxide materials have certain changes, but they are all sensitive to 5ppm NO at 80°C. 2 Gas has a relatively good response, and its response range is 39-88.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com