A kind of bio-enzyme composite preparation for oil recovery and its preparation method and application

A compound preparation and biological enzyme technology, applied in chemical instruments and methods, production fluids, earth-moving drilling, etc., can solve the problems of low activation efficiency of anaerobic microorganisms, unstable oil well huff and puff effect, poor adaptability of bacterial strains to oil reservoirs, etc. Achieve the effect of good on-site test effect, wide application range and lower process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation of the biological enzyme composite preparation A of embodiment 1 oil recovery

[0043] (1) Dissolving the functional microbial fermentation liquid in water, using a magnetic stirrer to stir at room temperature for 20 minutes at a speed of 175 rpm, to obtain a functional microbial fermentation liquid solution;

[0044] (2) Add nutrients to the functional microbial fermentation broth solution, and stir for 40 minutes at a rotation speed of 300 rpm and a temperature of 30° C. to obtain a mixed solution;

[0045] (3) The biological enzyme was added to the above mixed solution at a constant speed under the condition of heating while stirring. The stirring speed was 400 rpm, the stirring time was 75 min, and the heating temperature was 40 ° C. After the stirring was completed, the compound preparation A was obtained.

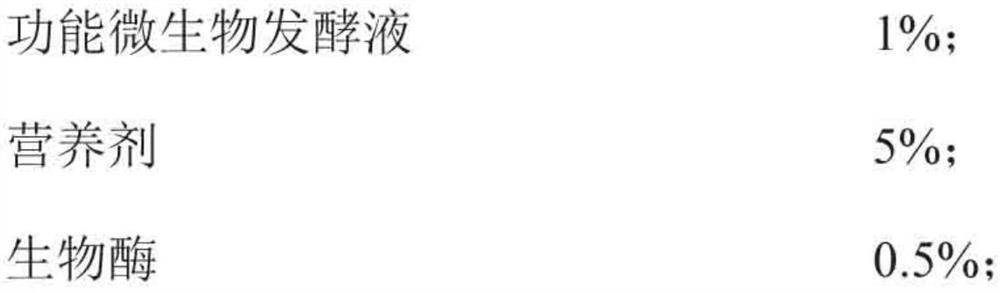

[0046] The composition and components (mass percentage) of the biological enzyme compound preparation A for oil recovery are as follows:

[0047...

Embodiment 2

[0052] The preparation of the biological enzyme compound preparation B of embodiment 2 oil recovery

[0053] (1) Dissolving the functional microbial fermentation liquid in water, using a magnetic stirrer to stir at room temperature for 30 minutes at a speed of 150 rpm, to obtain a functional microbial fermentation liquid solution;

[0054] (2) Add nutrients to the functional microbial fermentation broth solution, and stir for 30 minutes at a rotation speed of 250 rpm and a temperature of 35° C. to obtain a mixed solution;

[0055] (3) The biological enzyme was added to the above mixed solution at a constant speed under the condition of heating while stirring. The stirring speed was 350 rpm, the stirring time was 60 min, and the heating temperature was 35 ° C. After the stirring was completed, the compound preparation B was obtained.

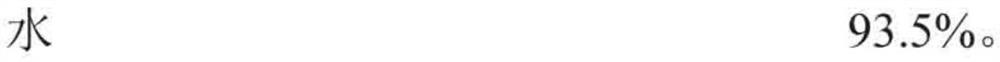

[0056] The composition and components (mass percentage) of the biological enzyme compound preparation B for oil recovery are as follows:

[005...

Embodiment 3

[0061] The preparation of the biological enzyme compound preparation C of embodiment 3 oil recovery

[0062] (1) Dissolving the functional microbial fermentation liquid in water, using a magnetic stirrer to stir at room temperature for 25 minutes at a speed of 200 rpm, to obtain a functional microbial fermentation liquid solution;

[0063] (2) Add nutrients to the functional microbial fermentation broth solution, and stir for 50 minutes at a rotation speed of 200 rpm and a temperature of 32° C. to obtain a mixed solution;

[0064] (3) The biological enzyme was added to the above mixed solution at a constant speed under the condition of heating while stirring. The stirring speed was 375rpm, the stirring time was 90min, and the heating temperature was 37.5°C. Composite preparation C was obtained after the stirring was completed.

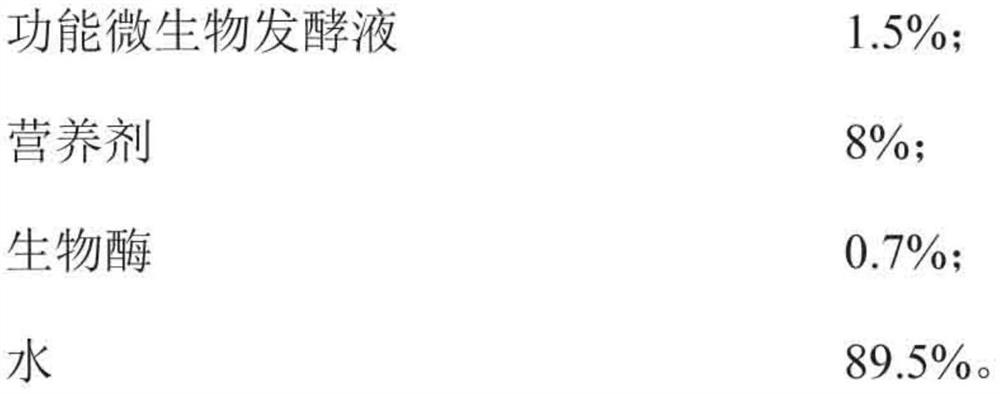

[0065] The composition and components (mass percentage) of the biological enzyme compound preparation C for oil recovery are as follows:

[0066] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com