Wood pulp fiber/nanometer barium sulfate composite lithium battery diaphragm paper and preparation method thereof

A lithium battery separator, nano barium sulfate technology, applied in lithium batteries, battery pack parts, non-aqueous electrolyte batteries, etc. Wetting and other problems, to achieve the effects of excellent wetting performance, moderate pore size, improved wettability and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

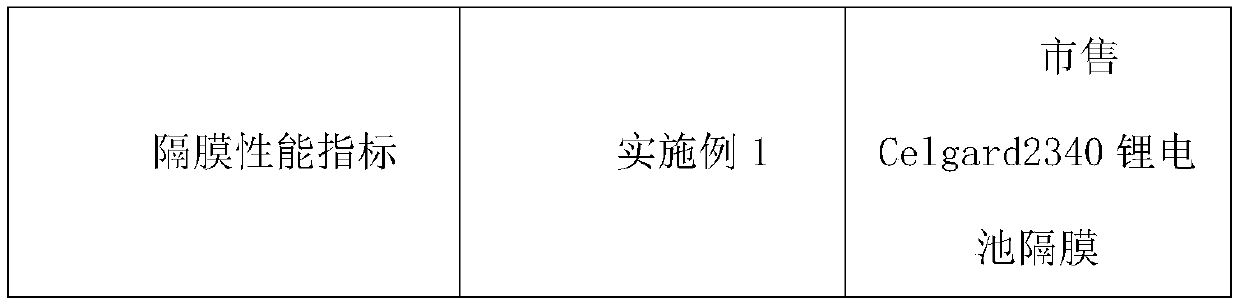

Embodiment 1

[0052] A kind of preparation method of wood pulp fiber / nano barium sulfate composite lithium battery separator paper, its steps are as follows:

[0053] (1) Mix the virgin softwood pulp fiber of 50% by mass and the hardwood pulp of 50% by mass that have been disintegrated, and carry out high-viscosity beating treatment to obtain mixed wood pulp with a beating degree of 80 ° SR Fiber slurry; the paper preparation process of high-density tissue paper is used to prepare a basis weight of 30g / m 2 fiber base paper.

[0054] (2) Mix 50% by mass of nanofibers (30±5nm in diameter, 50±5:1 aspect ratio) and 50% by mass of nanobarium sulfate composite material (30±5nm in diameter), and coat On both sides of the fiber base paper in step (1), the coating amount is 18g / m 2 , and use a hot press machine to carry out hot pressing and drying under the conditions of a temperature of 120 ° C and a pressure of 5 MPa to obtain a semi-finished lithium battery separator paper.

[0055] (3) dissol...

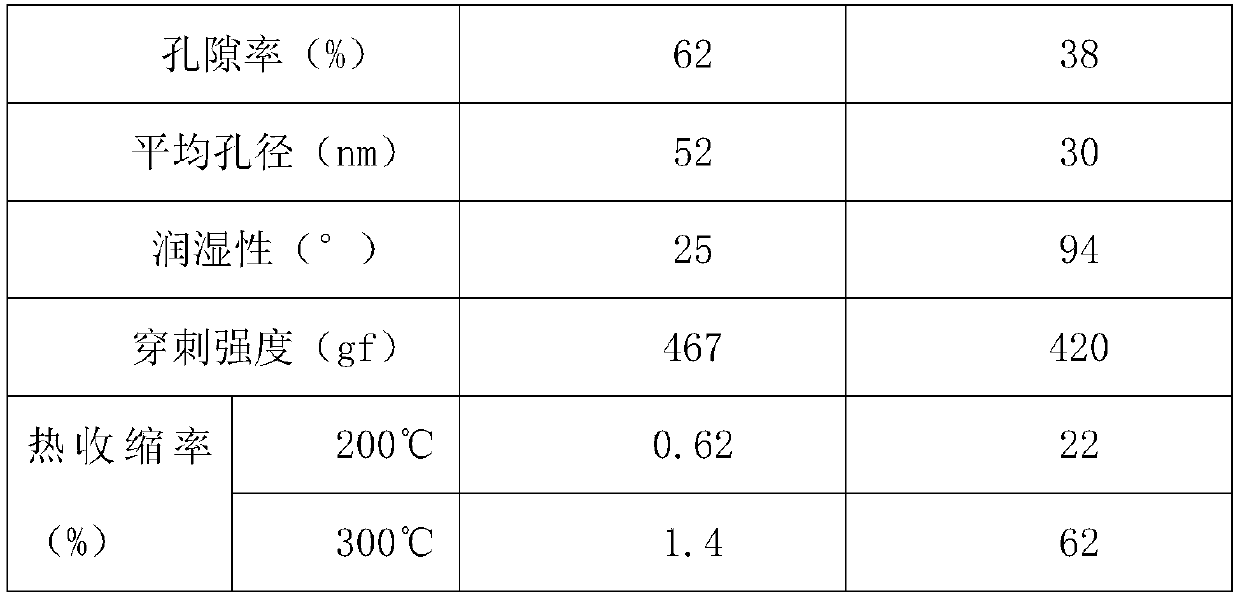

Embodiment 2

[0061] A kind of preparation method of wood pulp fiber / nano barium sulfate composite lithium battery separator paper, its steps are as follows:

[0062] (1) Carry out high-viscosity beating treatment to the original coniferous wood pulp fiber that has been decomposed, and the mixed wood pulp fiber slurry that the degree of beating is obtained is 80 ° SR; The paper preparation process of high-density tissue paper is used to prepare quantitatively 30g / m 2 fiber base paper.

[0063] (2) Mix 50% by mass of nanofibers (30±5nm in diameter, 50±5:1 aspect ratio) and 50% by mass of nano barium sulfate composite material (30±5nm in diameter), and coat On both sides of the fiber base paper in step (1), the coating amount is 18g / m 2 , and use a hot press machine to carry out hot pressing and drying under the conditions of a temperature of 120 ° C and a pressure of 5 MPa to obtain a semi-finished lithium battery separator paper.

[0064] (3) dissolving the polyimide resin with a dioxan...

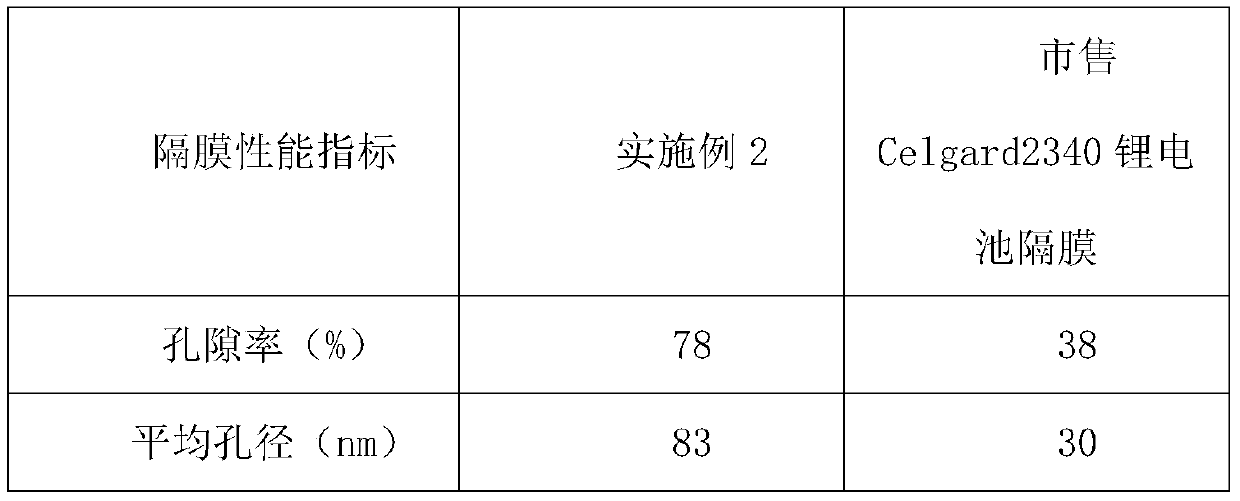

Embodiment 3

[0070] A kind of preparation method of wood pulp fiber / nano barium sulfate composite lithium battery separator paper, its steps are as follows:

[0071] (1) Carry out high-viscosity beating treatment to the original hardwood pulp fiber that has been disintegrated, and the obtained beating degree is 80 ° SR, fiber slurry; the prepared fiber slurry adopts the paper preparation process of high-density tissue paper The preparation quantity is 30g / m 2 fiber base paper.

[0072] (2) Mix 50% by mass of nanofibers (30±5nm in diameter, 50±5:1 aspect ratio) and 50% by mass of nano barium sulfate composite material (30±5nm in diameter), and coat On both sides of the fiber base paper in step (1), the coating amount is 18g / m 2 , and use a hot press machine to carry out hot pressing and drying under the conditions of a temperature of 120 ° C and a pressure of 5 MPa to obtain a semi-finished lithium battery separator paper.

[0073] (3) dissolving the polyimide resin with a dioxane solven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Aperture range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com