Three-dimensional porous graphene/attapulgite composite aerogel and preparation method thereof

A composite aerogel, three-dimensional porous technology, applied in chemical instruments and methods, alkali metal compounds, other chemical processes, etc., can solve the problems of undisclosed attapulgite and graphene, achieve excellent mechanical properties, improve stability, The effect of improving adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

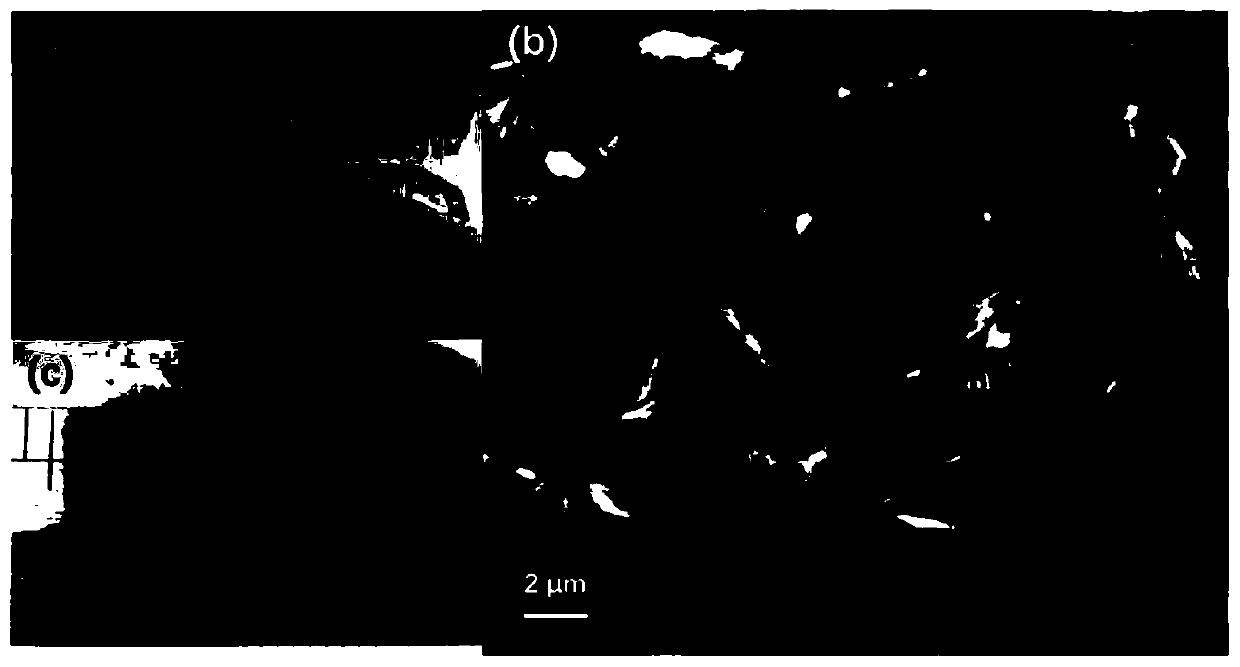

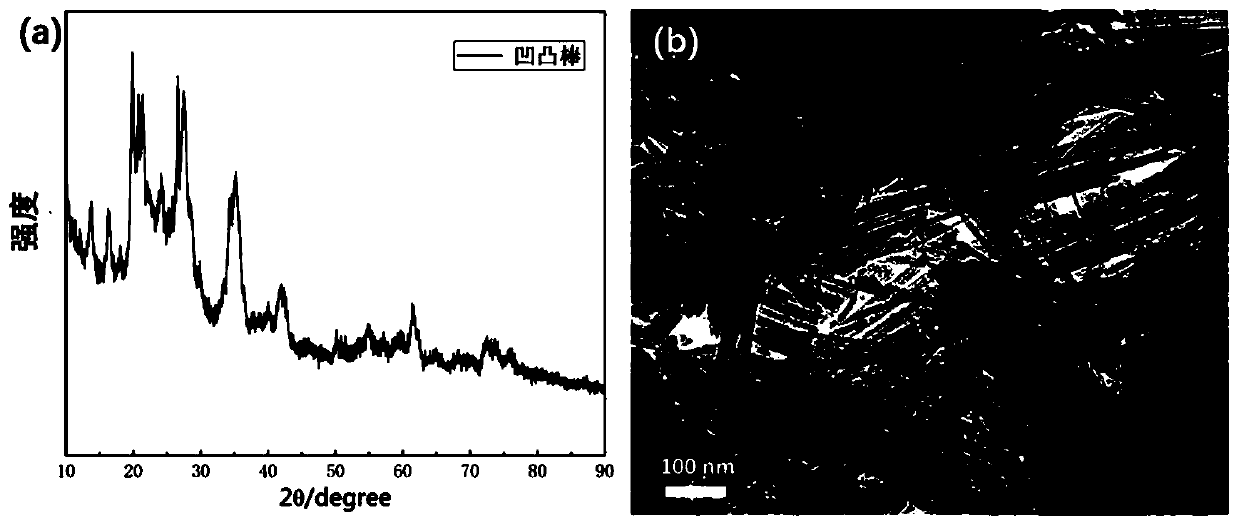

[0033] A preparation method of three-dimensional porous graphene / attapulgite composite airgel mainly adopts the following steps:

[0034] (1) Prepare a graphene oxide dispersion solution with a concentration of 1 to 50 mg / mL by a modified Hammers method;

[0035] (2) Utilize hydrochloric acid, sulfuric acid and / or phosphoric acid solution to modify the surface of the attapulgite, place the attapulgite in the hydrochloric acid, sulfuric acid and / or phosphoric acid solution, stir and centrifuge, the upper suspension is the attapulgite Suspension, the concentration is 1-100mg / mL;

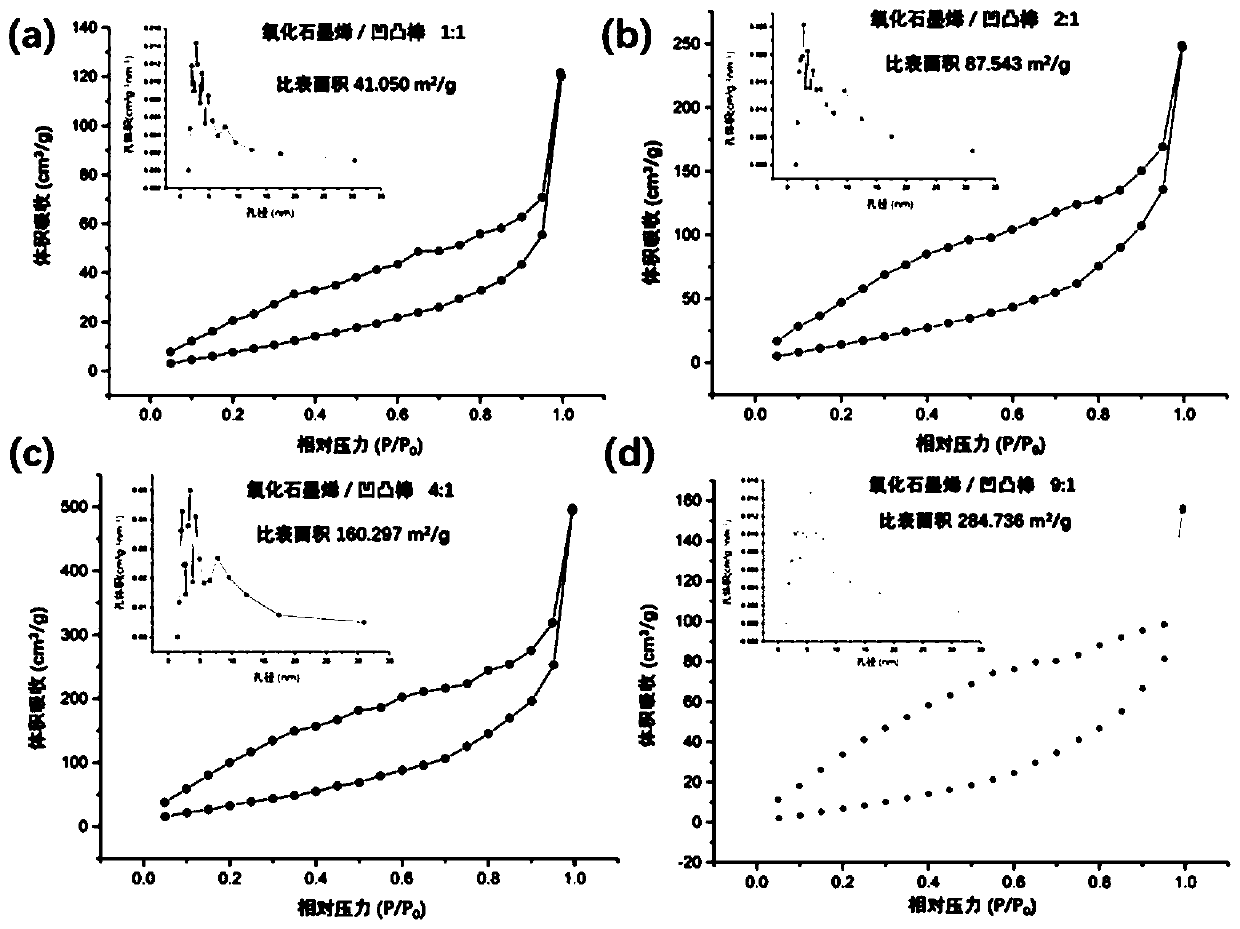

[0036] (3) Mix and stir the graphene oxide dispersion solution and the attapulgite suspension evenly, and the mass ratio of the attapulgite suspension to the graphene aqueous solution in the mixed solution is 1:1~1:10;

[0037] (4) The obtained mixed solution is self-assembled in a reaction kettle or any closed reaction vessel, the reaction temperature is controlled at 80-150°C, and the chemical react...

Embodiment 1

[0042] Add 2g of graphite and 1g of sodium nitrate to 46ml of concentrated sulfuric acid, ice bath and stir for 30min, then gradually add 6g of potassium permanganate, stir for 60min until the solution is purple-green, then stir for two hours at 37°C. Increase the temperature to 90°C, slowly add 92ml of deionized water and stir continuously with a glass rod, stir for 30min, add 124ml of deionized water, keep the temperature at about 35°C, then add 30ml of 30% hydrogen peroxide until no more bubbles are generated, the solution turns yellow. Wash 3 times with dilute hydrochloric acid and deionized water to obtain a graphene oxide solution.

[0043] Add the original attapulgite with a mass of 20mg into 100ml of deionized water, then add 1mol of sulfuric acid, stir for 24 hours, centrifuge and wash the solution 3 times, and finally take out the upper suspension, as a modified attapulgite suspension, the concentration is 40mg / mL.

[0044] Mix the prepared graphene oxide aqueous ...

Embodiment 2

[0048] Add 2g of graphite and 1g of sodium nitrate to 46ml of concentrated sulfuric acid, ice bath and stir for 30min, then gradually add 6g of potassium permanganate, stir for 60min until the solution is purple-green, then stir for two hours at 37°C. Increase the temperature to 100°C, slowly add 92ml of water and stir continuously with a glass rod, stir for 30min, add 124ml of deionized water, keep the temperature at about 35°C, then add 30ml of 30% hydrogen peroxide until no more bubbles are generated, and the solution becomes yellow. Wash 3 times with dilute hydrochloric acid and deionized water to obtain a graphene oxide solution.

[0049] The original attapulgite with a mass of 20mg was added to 100ml of deionized water, then 1.5mol of phosphoric acid was added, after stirring for 24 hours, the solution was centrifuged and cleaned 3 times, and then the upper suspension was taken out as a modified attapulgite suspension with a concentration of 40mg / mL.

[0050] Mix the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Channel diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com