Acidic-basic solid catalyst, preparation and application thereof in production of biodiesel

A solid catalyst, amphoteric technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc. The problem of easy leaching of active sites, etc., achieves the effect of universality, not easy to fall off, and high catalytic reaction yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

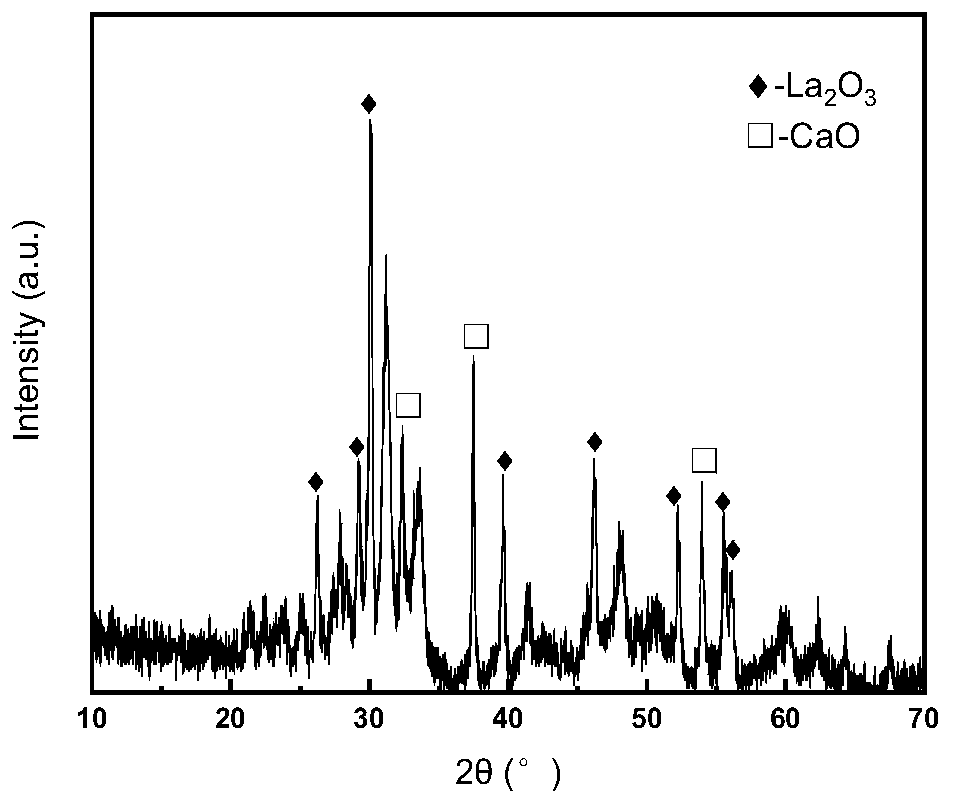

[0059] Weigh successively 3g halloysite, 12.63g Ca(NO 3 ) 2 4H 2 O, 8.98g La(NO 3 ) 3 and 34.21g of urea were mixed in deionized water, and stirred evenly to obtain a suspension. The suspension was placed in a hydrothermal reaction kettle, aged at 120° C. for 24 hours, and then cooled to room temperature. After filtration, the obtained solid was dried at 105°C for 14 hours, and then the product was calcined at a rate of 5°C / min from 50°C to 850°C for 5 hours to obtain a mass ratio of calcium oxide to halloysite of 1, And the acid-base amphoteric solid catalyst with a mass ratio of lanthanum oxide / calcium oxide of 1.5.

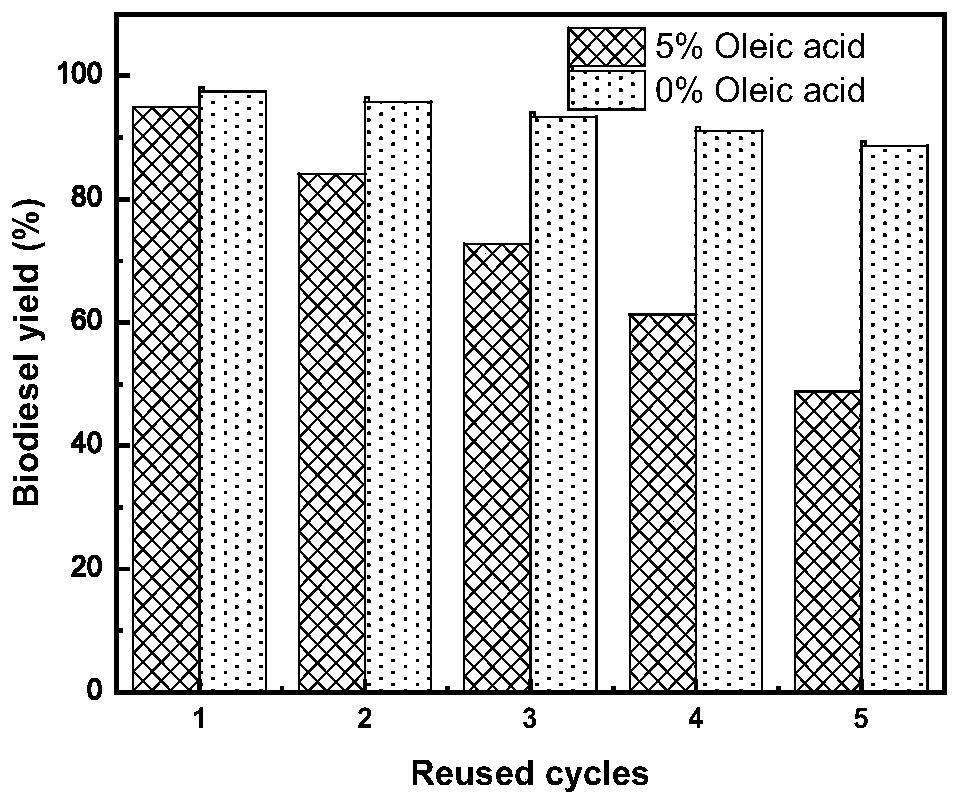

[0060] 12.64g of methanol, 20g of palm oil, 1g of oleic acid and 1.4g of catalyst were successively added into the autoclave, heated to 150°C under constant stirring at a rotational speed of 1200r / min and maintained for 2 hours. The reaction product is separated by a centrifuge to separate the solid catalyst, and the liquid product is placed in a separato...

Embodiment 2

[0062] Weigh successively 3g halloysite, 12.63g Ca(NO 3 ) 2 4H 2 O, 11.97g La(NO 3 ) 3 and 39.19g of urea were mixed in deionized water, and stirred evenly to obtain a suspension. The suspension was placed in a hydrothermal reaction kettle, aged at 120° C. for 24 hours, and then cooled to room temperature. After filtration, the obtained solid was dried at 105°C for 14 hours, and then the product was calcined at a rate of 5°C / min from 50°C to 850°C for 5 hours to obtain a mass ratio of calcium oxide to halloysite of 1, And the acid-base amphoteric solid catalyst with the mass ratio of lanthanum oxide / calcium oxide being 2.

[0063] 12.64g of methanol, 20g of palm oil, 1g of oleic acid and 1.4g of catalyst were successively added into the autoclave, heated to 150°C under constant stirring at a rotational speed of 1200r / min and maintained for 2 hours. The reaction product is separated by a centrifuge to separate the solid catalyst, and the liquid product is placed in a sepa...

Embodiment 3

[0065] Weigh successively 3g halloysite, 12.63g Ca(NO 3 ) 2 4H 2 O, 5.98g La(NO 3 ) 3 and 29.23g of urea were mixed in deionized water, and stirred evenly to obtain a suspension. The suspension was placed in a hydrothermal reaction kettle, aged at 120° C. for 24 hours, and then cooled to room temperature. After filtration, the obtained solid was dried at 105°C for 14 hours, and then the product was calcined at a rate of 5°C / min from 50°C to 850°C for 5 hours to obtain a mass ratio of calcium oxide to halloysite of 1, And the acid-base amphoteric solid catalyst with the mass ratio of lanthanum oxide / calcium oxide being 1.

[0066] 12.64g of methanol, 20g of palm oil, 1g of oleic acid and 1.4g of catalyst were successively added into the autoclave, heated to 150°C under constant stirring at a rotational speed of 1200r / min and maintained for 2 hours. The reaction product is separated by a centrifuge to separate the solid catalyst, and the liquid product is placed in a separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com