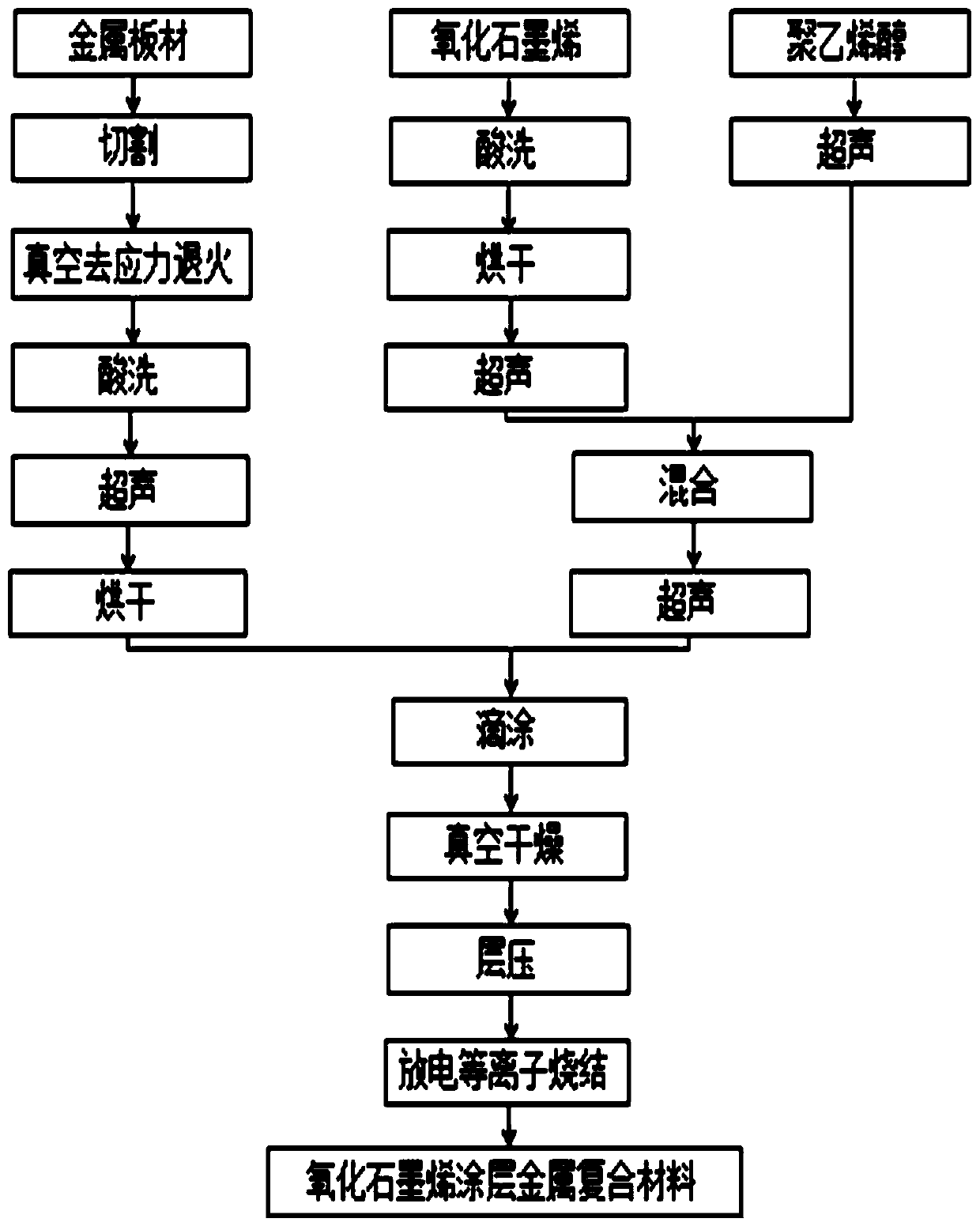

Preparation method of graphene oxide coating metal laminated composite material

A composite material, graphene technology, applied in metal layered products, chemical instruments and methods, coatings, etc., can solve problems such as complex interface bonding, improve corrosion resistance, structure and function integration, high densification, improve The effect of space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment includes the following steps:

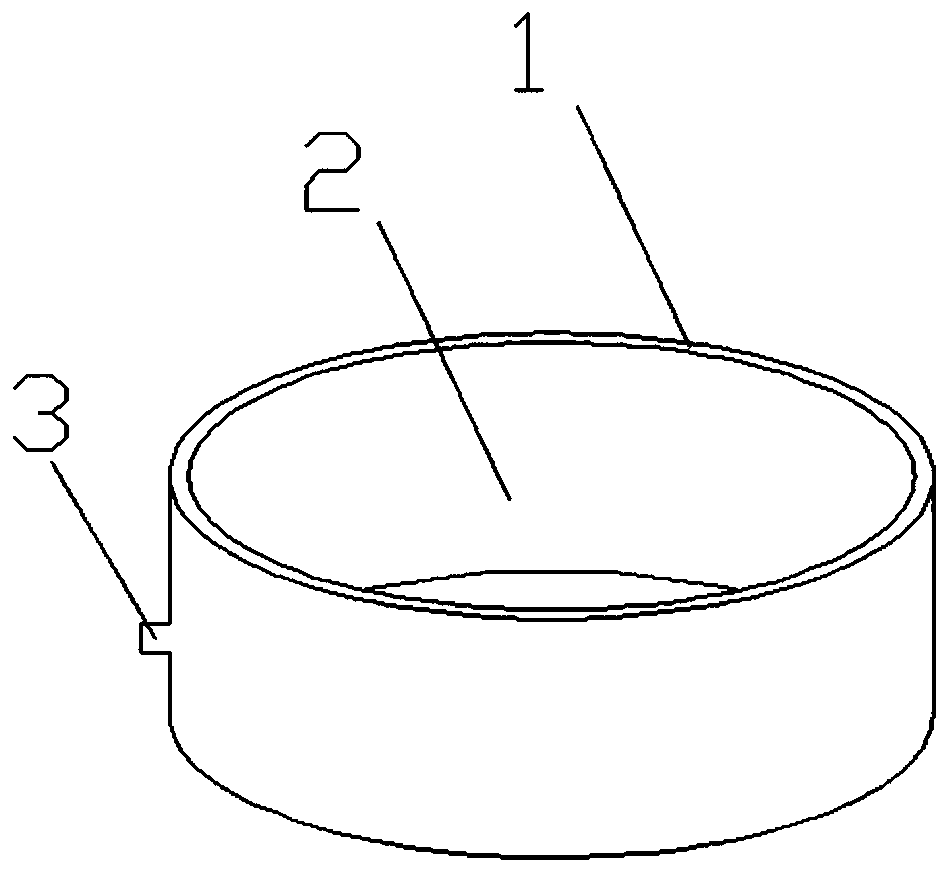

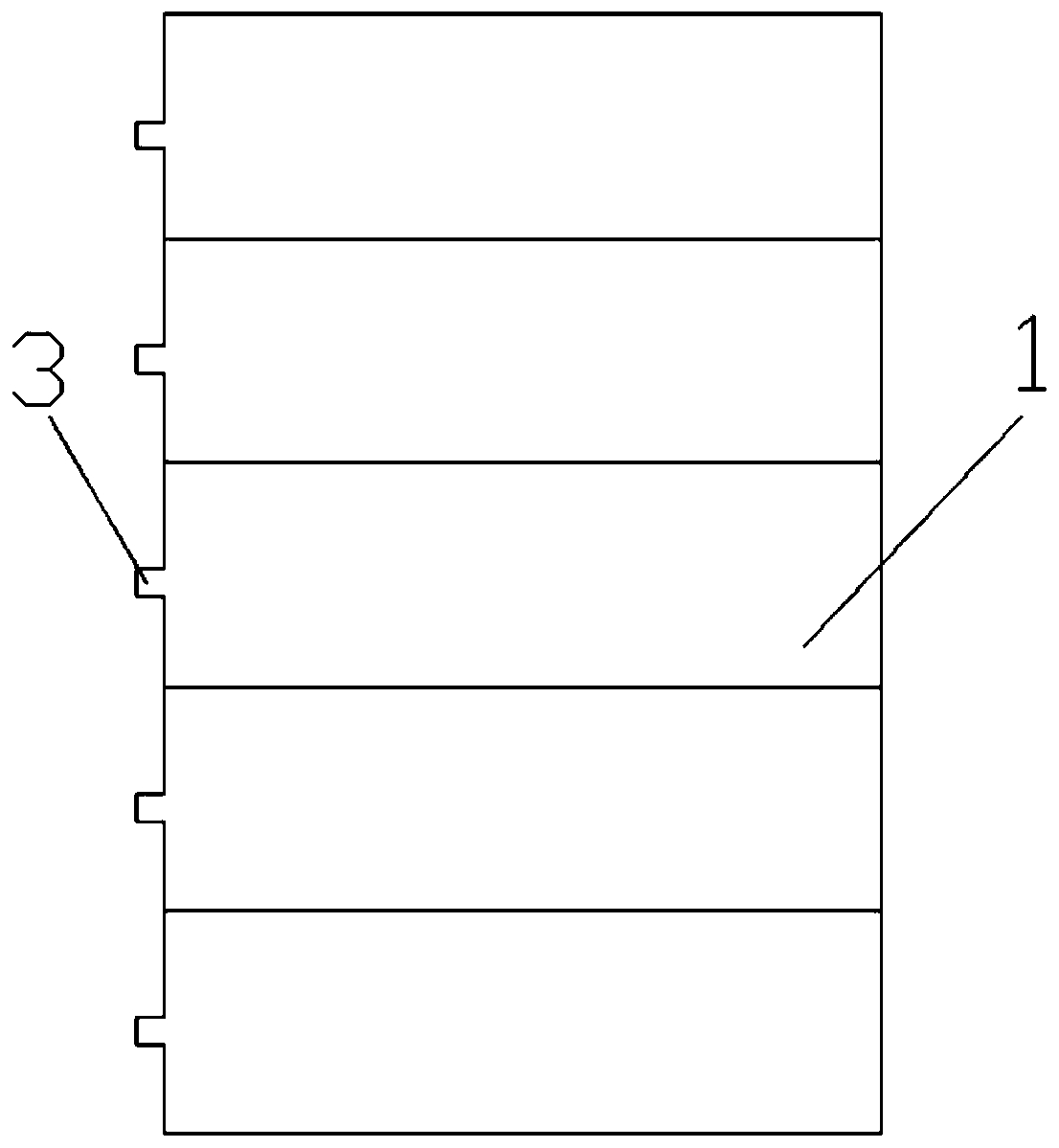

[0037] Step 1. Cut the titanium plate into circular titanium sheets with a thickness of 0.5mm and a diameter of 50mm by wire cutting, and then perform vacuum stress relief annealing treatment; the conditions for the vacuum stress relief annealing treatment are: under the condition of -0.1MPa, heating Keep warm for 4 hours after reaching 550°C;

[0038] Step 2. Put the titanium sheet after the vacuum stress relief annealing treatment in step 1 into the surface treatment solution for pickling for 3 minutes, then place it in acetone and ultrasonicate for 20 minutes at 42° C., and then perform drying treatment; the surface treatment solution It consists of 1mL hydrofluoric acid solution with a mass concentration of 20%, 1.5mL nitric acid solution with a mass concentration of 60%, and 5000mL deionized water;

[0039] Step 3, place the graphene oxide prepared by the Hummers method in the surface treatment solution described in ...

Embodiment 2

[0045] This embodiment includes the following steps:

[0046] Step 1. Cut the TC4 titanium alloy plate into circular TC4 titanium alloy sheets with a thickness of 1 mm and a diameter of 50 mm by wire cutting, and then perform vacuum stress relief annealing treatment; the conditions for the vacuum stress relief annealing treatment are: at -0.1MPa , heated to 570°C and then kept for 3 hours;

[0047] Step 2. Put the TC4 titanium alloy sheet after the vacuum stress relief annealing treatment in step 1 into the surface treatment solution for pickling for 4 minutes, then place it in acetone and ultrasonicate for 30 minutes at 50° C., and then perform drying treatment; the surface The treatment solution is composed of 1.5mL hydrofluoric acid solution with a mass concentration of 20%, 3mL nitric acid solution with a mass concentration of 60%, and 2000mL deionized water;

[0048] Step 3, place the graphene oxide prepared by the Hummers method in the surface treatment solution describ...

Embodiment 3

[0053] This embodiment includes the following steps:

[0054] Step 1. Cut the aluminum sheet into circular aluminum sheets with a thickness of 0.1mm and a diameter of 10mm by wire cutting, and then perform vacuum stress relief annealing treatment; the conditions for the vacuum stress relief annealing treatment are: under the condition of -0.1MPa, heating Keep warm at 400°C for 1 hour;

[0055] Step 2. Put the aluminum sheet after the vacuum stress relief annealing treatment in step 1 into the surface treatment solution for pickling for 3 minutes, then place it in acetone and ultrasonicate for 10 minutes at 30° C., and then perform drying treatment; the surface treatment solution It consists of 1mL hydrofluoric acid solution with a mass concentration of 20%, 1mL nitric acid solution with a mass concentration of 60%, and 1000mL deionized water;

[0056] Step 3, place the graphene oxide prepared by the Hummers method in the surface treatment solution described in step 2 and pick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com