Ultrathin graphene and preparation method thereof

A graphene and ultra-thin technology, applied in the field of graphene, can solve the problems of low quality of graphene materials, unsuitable for mass production, complicated process flow, etc., and achieve the effects of simple method, uniform size, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

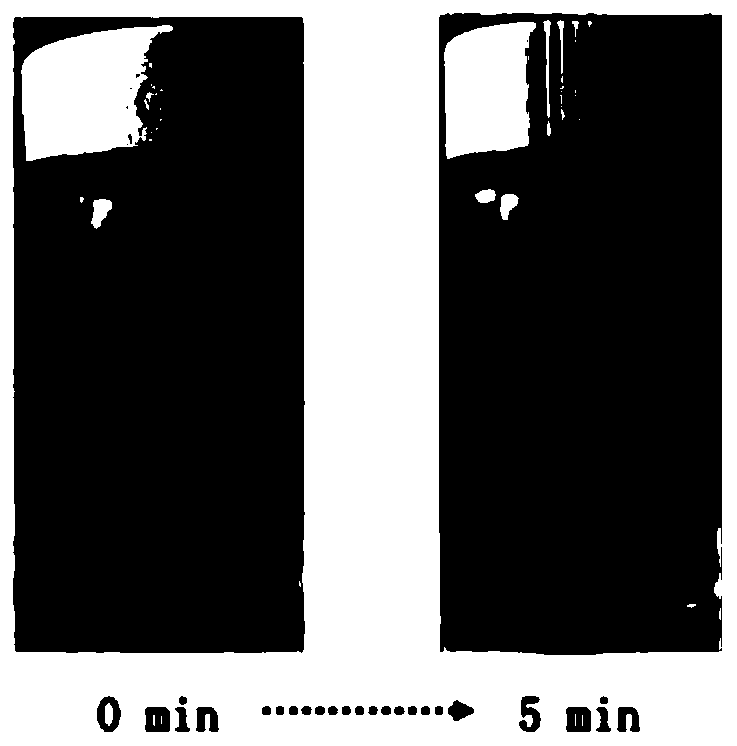

Image

Examples

preparation example Construction

[0030] A kind of preparation method of ultrathin graphene is characterized in that, it comprises the following steps:

[0031] S1 raw material mixing: solid organic matter composed of one or more of glucose, citric acid, and fructose in any proportion, and one or more of sodium chloride, potassium chloride, and calcium chloride in any proportion The combined molten salt is uniformly mixed in a weight ratio of 1:5 to 100 to obtain a mixture;

[0032] S2 thermal polymerization reaction: move the obtained mixture to a corundum boat at the bottom of the arc, and place it in a horizontal high-temperature tube furnace. In an inert gas environment composed of the above kinds in any proportion, the temperature is raised to 1000-1400°C at a heating rate of 1-10°C / min for 3-10h, and high-temperature thermal polymerization is carried out to generate graphene.

[0033] The graphene prepared by the present invention has a layer thickness less than 3nm.

Embodiment 1

[0035] The preparation method of graphene, it may further comprise the steps:

[0036] S1 Mixing of raw materials: Mix solid organic matter and molten salt at a weight ratio of 1:50 to obtain a mixture; wherein, the solid organic matter is made by mixing glucose, citric acid, and fructose at a weight ratio of 1:1:1; wherein, the molten salt It is formed by mixing sodium chloride, potassium chloride and calcium chloride at a ratio of 1:1:1 by weight;

[0037] S2 thermal polymerization reaction: move the obtained mixture to a corundum boat at the bottom of the arc, and place it in a horizontal high-temperature tube furnace with a flow rate of 400mL / min in an inert gas environment, and raise the temperature to 1200°C at a rate of 6°C / min Keeping the temperature for 7 hours, performing high-temperature thermal polymerization to generate ultra-thin graphene; wherein, the inert gas is nitrogen, argon, and helium mixed in a ratio of 1:1:1 by weight.

[0038] The graphene prepared in...

Embodiment 2

[0040] The preparation method of ultrathin graphene, it comprises the following steps:

[0041] S1 raw material mixing: glucose and sodium chloride molten salt are uniformly mixed at a weight ratio of 1:5 to obtain a mixture;

[0042] S2 thermal polymerization reaction: move the obtained mixture into a corundum boat at the bottom of the arc, and place it in a horizontal high-temperature tube furnace, and raise the temperature to 1000°C at a rate of 1°C / min under a nitrogen atmosphere with a flow rate of 100mL / min Insulate for 3 hours, and carry out high-temperature thermal polymerization to generate graphene.

[0043] The graphene prepared in this embodiment has a layer thickness of 2 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com