System and method for advanced treatment of wastewater containing high-concentration organic amines

An advanced treatment, organic amine technology, applied in water/sewage treatment, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve problems such as inapplicability, and achieve the effects of improving utilization, preventing damage, and simple regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

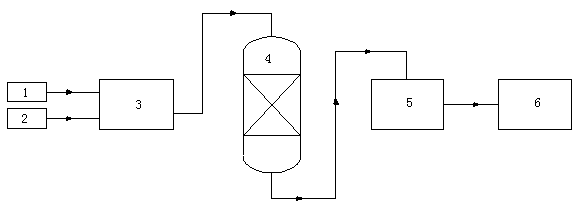

[0038] 10L of organic amine industrial wastewater is transported from waste water storage tank 1 to ozone compound oxidation pool 3 through pipelines, and 6g of compound oxidants (3g hydrogen peroxide, 3g sodium hypochlorite) are transported from compound oxidizer storage tank 2 to ozone compound oxidation pool 3 through pipelines, and ozone compound The pH of the solution in the oxidation tank 3 is adjusted to 2 with formic acid, the reaction temperature is 45°C, the wastewater solution is reacted in the ozone composite oxidation tank 3 for 60 minutes, the dosage of ozone is 120g / h, and then transported to the heterogeneous catalytic oxidation reactor through the pipeline 4 top inlet, modified molecular sieve (100g) is used as the carrier in the heterogeneous catalytic oxidation reactor 4, and the flow rate is 3L / h, and the waste water solution is transported to the sedimentation tank 5 from the bottom outlet of the heterogeneous catalytic oxidation reactor 4 through pipelines,...

Embodiment 2

[0040] 15L of methylamine industrial wastewater is transported from waste water storage tank 1 to ozone compound oxidation pool 3 through pipelines, and 10g of compound oxidants (4g of chlorine dioxide, 6g of sodium perchlorate) is transported from compound oxidizer storage tank 2 to ozone compound oxidation pool 3 through pipelines , the pH of the solution in the ozone composite oxidation tank 3 was adjusted to 3 with acetic acid, the reaction temperature was 55°C, the wastewater solution was reacted in the ozone composite oxidation tank 3 for 45min, and the dosage of ozone was 150g / h, and then transported to the heterogeneous catalyst via pipeline Oxidation reactor 4 top inlet, modified molecular sieve (100g) is used as carrier in heterogeneous catalytic oxidation reactor 4, flow rate is 4L / h, waste water solution is transported to sedimentation tank from the bottom outlet of heterogeneous catalytic oxidation reactor 4 through pipeline 5. Wastewater enters the biochemical sys...

Embodiment 3

[0042]20L methylamine industrial wastewater is transported from waste water storage tank 1 to ozone composite oxidation pool 3 through pipelines, and 15g composite oxidant (6g hydrogen peroxide, 9g sodium chlorate) is transported from composite oxidation storage tank 2 to ozone composite oxidation pool 3 through pipelines, The pH of the solution in the ozone composite oxidation tank 3 is adjusted to 4 with hydrochloric acid, the reaction temperature is 65°C, the wastewater solution is reacted in the ozone composite oxidation tank 3 for 50 minutes, and the dosage of ozone is 170g / h, and then transported to the heterogeneous catalytic oxidation through the pipeline Reactor 4 top inlet, modified molecular sieve (100g) is used as carrier in heterogeneous catalytic oxidation reactor 4, flow rate is 3.5L / h, waste water solution is transported to sedimentation tank through pipeline from the bottom outlet of heterogeneous catalytic oxidation reactor 4 5. Waste water is treated with pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com